Imagine a world where materials bend to our will, where strength and resilience are at our fingertips. In this captivating blog post, we dive into the fascinating realm of metal hardness comparison. Uncover the secrets behind Vickers, Brinell, and Rockwell scales, as our expert mechanical engineer guides you through the intricacies of this essential topic. Get ready to expand your knowledge and master the art of material selection.

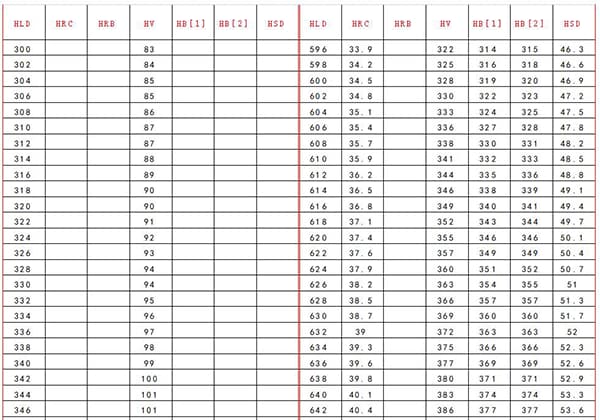

Hardness testing is the simplest and most straightforward method among mechanical property tests. In order to replace certain mechanical property tests with hardness tests, a relatively accurate conversion relationship between hardness and strength is needed in production.

Experience has shown that there is an approximate corresponding relationship between the various hardness values of metal materials, and between hardness values and strength values. This is because the hardness value is determined by the initial plastic deformation resistance and the continued plastic deformation resistance. The higher the strength of the material, the higher the plastic deformation resistance, and thus the higher the hardness value.

| Tensile strength N/mm2 | Vickers hardness | Brinell hardness | Rockwell hardness |

| Rm | HV | HB | HRC |

| 250 | 80 | 76 | |

| 270 | 85 | 80.7 | |

| 285 | 90 | 85.2 | |

| 305 | 95 | 90.2 | |

| 320 | 100 | 95 | |

| 335 | 105 | 99.8 | |

| 350 | 110 | 105 | |

| 370 | 115 | 109 | |

| 380 | 120 | 114 | |

| 400 | 125 | 119 | |

| 415 | 130 | 124 | |

| 430 | 135 | 128 | |

| 450 | 140 | 133 | |

| 465 | 145 | 138 | |

| 480 | 150 | 143 | |

| 490 | 155 | 147 | |

| 510 | 160 | 152 | |

| 530 | 165 | 156 | |

| 545 | 170 | 162 | |

| 560 | 175 | 166 | |

| 575 | 180 | 171 | |

| 595 | 185 | 176 | |

| 610 | 190 | 181 | |

| 625 | 195 | 185 | |

| 640 | 200 | 190 | |

| 660 | 205 | 195 | |

| 675 | 210 | 199 | |

| 690 | 215 | 204 | |

| 705 | 220 | 209 | |

| 720 | 225 | 214 | |

| 740 | 230 | 219 | |

| 755 | 235 | 223 | |

| 770 | 240 | 228 | 20.3 |

| 785 | 245 | 233 | 21.3 |

| 800 | 250 | 238 | 22.2 |

| 820 | 255 | 242 | 23.1 |

| 835 | 260 | 247 | 24 |

| 850 | 265 | 252 | 24.8 |

| 865 | 270 | 257 | 25.6 |

| 880 | 275 | 261 | 26.4 |

| 900 | 280 | 266 | 27.1 |

| 915 | 285 | 271 | 27.8 |

| 930 | 290 | 276 | 28.5 |

| 950 | 295 | 280 | 29.2 |

| 965 | 300 | 285 | 29.8 |

| 995 | 310 | 295 | 31 |

| 1030 | 320 | 304 | 32.2 |

| 1060 | 330 | 314 | 33.3 |

| 1095 | 340 | 323 | 34.4 |

| 1125 | 350 | 333 | 35.5 |

| 1115 | 360 | 342 | 36.6 |

| 1190 | 370 | 352 | 37.7 |

| 1220 | 380 | 361 | 38.8 |

| 1255 | 390 | 371 | 39.8 |

| 1290 | 400 | 380 | 40.8 |

| 1320 | 410 | 390 | 41.8 |

| 1350 | 420 | 399 | 42.7 |

| 1385 | 430 | 409 | 43.6 |

| 1420 | 440 | 418 | 44.5 |

| 1455 | 450 | 428 | 45.3 |

| 1485 | 460 | 437 | 46.1 |

| 1520 | 470 | 447 | 46.9 |

| 1557 | 480 | 456 | 47 |

| 1595 | 490 | 466 | 48.4 |

| 1630 | 500 | 475 | 49.1 |

| 1665 | 510 | 485 | 49.8 |

| 1700 | 520 | 494 | 50.5 |

| 1740 | 530 | 504 | 51.1 |

| 1775 | 540 | 513 | 51.7 |

| 1810 | 550 | 523 | 52.3 |

| 1845 | 560 | 532 | 53 |

| 1880 | 570 | 542 | 53.6 |

| 1920 | 580 | 551 | 54.1 |

| 1955 | 590 | 561 | 54.7 |

| 1995 | 600 | 570 | 55.2 |

| 2030 | 610 | 580 | 55.7 |

| 2070 | 620 | 589 | 56.3 |

| 2105 | 630 | 599 | 56.8 |

| 2145 | 640 | 608 | 57.3 |

| 2180 | 650 | 618 | 57.8 |

| 660 | 58.3 | ||

| 670 | 58.8 | ||

| 680 | 59.2 | ||

| 690 | 59.7 | ||

| 700 | 60.1 | ||

| 720 | 61 | ||

| 740 | 61.8 | ||

| 760 | 62.5 | ||

| 780 | 63.3 | ||

| 800 | 64 | ||

| 820 | 64.7 | ||

| 840 | 65.3 | ||

| 860 | 65.9 | ||

| 880 | 66.4 | ||

| 900 | 67 | ||

| 920 | 67.5 | ||

| 940 |

| Rockwell | Rockwell | Vickers | Brinell | Tensile strength |

| HRC | HRA | HV | HB | N/mm2 |

| 17 | — | 211 | 211 | 710 |

| 17.5 | — | 214 | 214 | 715 |

| 18 | — | 216 | 216 | 725 |

| 18.5 | — | 218 | 218 | 730 |

| 19 | — | 221 | 220 | 735 |

| 19.5 | — | 223 | 222 | 745 |

| 20 | — | 226 | 225 | 750 |

| 20.5 | — | 229 | 227 | 760 |

| 21 | — | 231 | 229 | 765 |

| 21.5 | — | 234 | 232 | 775 |

| 22 | — | 237 | 234 | 785 |

| 22.5 | — | 240 | 237 | 790 |

| 23 | — | 243 | 240 | 800 |

| 23.5 | — | 246 | 242 | 810 |

| 24 | — | 249 | 245 | 820 |

| 24.5 | — | 252 | 248 | 830 |

| 25 | — | 255 | 251 | 835 |

| 25.5 | — | 258 | 254 | 850 |

| 26 | — | 261 | 257 | 860 |

| 26.5 | — | 264 | 260 | 870 |

| 27 | — | 268 | 263 | 880 |

| 27.5 | — | 271 | 266 | 890 |

| 28 | — | 274 | 269 | 900 |

| 28.5 | — | 278 | 273 | 910 |

| 29 | — | 281 | 276 | 920 |

| 29.5 | — | 285 | 280 | 935 |

| 30 | — | 289 | 283 | 950 |

| 30.5 | — | 292 | 287 | 960 |

| 31 | — | 296 | 291 | 970 |

| 31.5 | — | 300 | 294 | 980 |

| 32 | — | 304 | 298 | 995 |

| 32.5 | — | 308 | 302 | 1010 |

| 33 | — | 312 | 306 | 1020 |

| 33.5 | — | 316 | 310 | 1035 |

| 34 | — | 320 | 314 | 1050 |

| 34.5 | — | 324 | 318 | 1065 |

| 35 | — | 329 | 323 | 1080 |

| 35.5 | — | 333 | 327 | 1095 |

| 36 | — | 338 | 332 | 1110 |

| 36.5 | — | 342 | 336 | 1125 |

| 37 | — | 347 | 341 | 1140 |

| 37.5 | — | 352 | 345 | 1160 |

| 38 | — | 357 | 350 | 1175 |

| 38.5 | — | 362 | 355 | 1190 |

| 39 | 70 | 367 | 360 | 1210 |

| 39.5 | 70.3 | 372 | 365 | 1225 |

| 40 | 70.8 | 382 | 375 | 1260 |

| 40.5 | 70.5 | 377 | 370 | 1245 |

| 41 | 71.1 | 388 | 380 | 1280 |

| 41.5 | 71.3 | 393 | 385 | 1300 |

| 42 | 71.6 | 399 | 391 | 1320 |

| 42.5 | 71.8 | 405 | 396 | 1340 |

| 43 | 72.1 | 411 | 401 | 1360 |

| 43.5 | 72.4 | 417 | 407 | 1385 |

| 44 | 72.6 | 423 | 413 | 1405 |

| 44.5 | 72.9 | 429 | 418 | 1430 |

| 45 | 73.2 | 436 | 424 | 1450 |

| 45.5 | 73.4 | 443 | 430 | 1475 |

| 46 | 73.7 | 449 | 436 | 1500 |

| 46.5 | 73.9 | 456 | 442 | 1525 |

| 47 | 74.2 | 463 | 449 | 1550 |

| 47.5 | 74.5 | 470 | 455 | 1575 |

| 48 | 74.7 | 478 | 461 | 1605 |

| 48.5 | 75 | 485 | 468 | 1630 |

| 49 | 75.3 | 493 | 474 | 1660 |

| 49.5 | 75.5 | 501 | 481 | 1690 |

| 50 | 75.8 | 509 | 488 | 1720 |

| 50.5 | 76.1 | 517 | 494 | 1750 |

| 51 | 76.3 | 525 | 501 | 1780 |

| 51.5 | 76.6 | 534 | — | 1815 |

| 52 | 76.9 | 543 | — | 1850 |

| 52.5 | 77.1 | 551 | — | 1885 |

| 53 | 77.4 | 561 | — | 1920 |

| 53.5 | 77.7 | 570 | — | 1955 |

| 54 | 77.9 | 579 | — | 1995 |

| 54.5 | 78.2 | 589 | — | 2035 |

| 55 | 78.5 | 599 | — | 2075 |

| 55.5 | 78.7 | 609 | — | 2115 |

| 56 | 79 | 620 | — | 2160 |

| 56.5 | 79.3 | 631 | — | 2205 |

| 57 | 79.5 | 642 | — | 2250 |

| 57.5 | 79.8 | 653 | — | 2295 |

| 58 | 80.1 | 664 | — | 2345 |

| 58.5 | 80.3 | 676 | — | 2395 |

| 59 | 80.6 | 688 | — | 2450 |

| 59.5 | 80.9 | 700 | — | 2500 |

| 60 | 81.2 | 713 | — | 2555 |

| 60.5 | 81.4 | 726 | — | — |

| 61 | 81.7 | 739 | — | — |

| 61.5 | 82 | 752 | — | — |

| 62 | 82.2 | 766 | — | — |

| 62.5 | 82.5 | 780 | — | — |

| 63 | 82.8 | 795 | — | — |

| 63.5 | 83.1 | 810 | — | — |

| 64 | 83.3 | 825 | — | — |

| 64.5 | 83.6 | 840 | — | — |

| 65 | 83.9 | 856 | — | — |

| 65.5 | 84.1 | 872 | — | — |

| 66 | 84.4 | 889 | — | — |

| 66.5 | 84.7 | 906 | — | — |

| 67 | 85 | 923 | — | — |

| 67.5 | 85.2 | 941 | — | — |

| 68 | 85.5 | 959 | — | — |

| 68.5 | 85.8 | 978 | — | — |

| 69 | 86.1 | 997 | — | — |

| 69.5 | 86.3 | 1017 | — | — |

| 70 | 86.6 | 1037 | — | — |

| Rockwell hardness | Surface Rockwell hardness | Vickers | Brinell | Shore | |||||

| HRA | HRB | HRC | HRD | 15N | 30N | 45N | HV | HB | HS |

| 60kgf | 100kgf | 150kgf | 100kgf | 15kgf | 30kgf | 45kgf | 50kgf | 3000kgf | JIS |

| 85.6 | 68 | 76.9 | 93.2 | 84.4 | 75.4 | 940 | 97.6 | ||

| 85.3 | 67.5 | 76.5 | 93 | 84 | 74.3 | 920 | 96.4 | ||

| 85 | 67 | 76.1 | 92.9 | 83.6 | 74.2 | 900 | 95.2 | ||

| 84.7 | 66.5 | 75.7 | 92.7 | 83.1 | 73.6 | 880 | 94 | ||

| 84.4 | 65.9 | 75.3 | 92.5 | 82.7 | 73.1 | 860 | 92.8 | ||

| 84.1 | 65.3 | 74.8 | 92.3 | 82.2 | 72.2 | 840 | 91.5 | ||

| 83.8 | 64.7 | 74.3 | 92.1 | 81.7 | 71.8 | 820 | 90.2 | ||

| 83.4 | 64 | 73.8 | 91.8 | 81.1 | 71 | 800 | 88.9 | ||

| 83 | 63.3 | 73.3 | 91.5 | 80.4 | 70.2 | 780 | 87.5 | ||

| 82.6 | 62.5 | 72.6 | 91.2 | 79.7 | 69.4 | 760 | 86.2 | ||

| 82.2 | 61.8 | 72.1 | 91 | 79.1 | 68.6 | 740 | 84.8 | ||

| 81.8 | 61 | 71.5 | 90.7 | 78.4 | 67.7 | 720 | 83.3 | ||

| 81.3 | 60.1 | 70.8 | 90.3 | 77.6 | 66.7 | 700 | 81.8 | ||

| 81.1 | 59.7 | 70.5 | 90.1 | 77.2 | 66.2 | 690 | 81.1 | ||

| 80.8 | 59.2 | 70.1 | 89.8 | 76.8 | 65.7 | 680 | 80.3 | ||

| 80.6 | 58.8 | 69.8 | 89.7 | 76.4 | 65.3 | 670 | 79.6 | ||

| 80.3 | 58.3 | 69.4 | 89.5 | 75.9 | 64.7 | 660 | 78.8 | ||

| 80 | 57.8 | 69 | 89.2 | 75.5 | 64.1 | 650 | 78 | ||

| 79.8 | 57.3 | 68.7 | 89 | 75.1 | 63.5 | 640 | 77.2 | ||

| 79.5 | 56.8 | 68.3 | 88.8 | 74.6 | 63 | 630 | 76.4 | ||

| 79.2 | 56.3 | 67.9 | 88.5 | 74.2 | 62.4 | 620 | 75.6 | ||

| 78.9 | 55.7 | 67.5 | 88.2 | 73.6 | 61.7 | 610 | 74.7 | ||

| 78.6 | 55.2 | 67 | 88 | 73.2 | 61.2 | 600 | 73.9 | ||

| 78.4 | 54.7 | 66.7 | 87.8 | 72.7 | 60.5 | 590 | 73.1 | ||

| 78 | 54.1 | 66.2 | 87.5 | 72.1 | 59.9 | 580 | 72.2 | ||

| 77.8 | 53.6 | 65.8 | 87.2 | 71.7 | 59.3 | 570 | 71.3 | ||

| 77.4 | 53 | 65.4 | 86.9 | 71.2 | 58.6 | 560 | 70.4 | ||

| 77 | 52.3 | 64.8 | 86.6 | 70.5 | 57.8 | 550 | 505 | 69.6 | |

| 76.7 | 51.7 | 64.4 | 86.3 | 70 | 57 | 540 | 496 | 68.7 | |

| 76.4 | 51.1 | 63.9 | 86 | 69.5 | 56.2 | 530 | 488 | 67.7 | |

| 76.1 | 50.5 | 63.5 | 85.7 | 69 | 55.6 | 520 | 480 | 66.8 | |

| 75.7 | 49.8 | 62.9 | 85.4 | 68.3 | 54.7 | 510 | 473 | 65.9 | |

| 75.3 | 49.1 | 62.2 | 85 | 67.7 | 53.9 | 500 | 465 | 64.9 | |

| 74.9 | 48.4 | 61.6 | 84.7 | 67.1 | 53.1 | 490 | 456 | 64 | |

| 74.5 | 47.7 | 61.3 | 84.3 | 66.4 | 52.2 | 480 | 448 | 63 | |

| 74.1 | 46.9 | 60.7 | 83.9 | 65.7 | 51.3 | 470 | 441 | 62 | |

| 73.6 | 46.1 | 60.1 | 83.6 | 64.9 | 50.4 | 460 | 433 | 61 | |

| 73.3 | 45.3 | 59.4 | 83.2 | 64.3 | 49.4 | 450 | 425 | 60 | |

| 72.8 | 44.5 | 58.8 | 82.8 | 63.5 | 48.4 | 440 | 415 | 59 | |

| 72.3 | 43.6 | 58.2 | 82.3 | 62.7 | 47.4 | 430 | 405 | 58 | |

| 71.8 | 42.7 | 57.5 | 81.8 | 61.9 | 46.4 | 420 | 397 | 56.9 | |

| 71.4 | 41.8 | 56.8 | 81.4 | 61.1 | 45.3 | 410 | 388 | 55.9 | |

| 70.8 | 40.8 | 65 | 81 | 60.2 | 44.1 | 400 | 379 | 54.8 | |

| 70.3 | 39.8 | 55.2 | 80.3 | 59.3 | 42.9 | 390 | 369 | 53.7 | |

| 69.8 | 110 | 38.8 | 54.4 | 79.8 | 58.4 | 41.7 | 380 | 360 | 52.6 |

| 69.2 | 37.7 | 53.6 | 79.2 | 57.4 | 40.4 | 370 | 350 | 51.5 | |

| 68.7 | 109 | 36.6 | 52.8 | 78.6 | 56.4 | 39.1 | 360 | 341 | 50.4 |

| 68.1 | 35.5 | 51.9 | 78 | 55.4 | 37.8 | 350 | 331 | 49.3 | |

| 67.6 | 108 | 34.4 | 51.1 | 77.4 | 54.4 | 36.5 | 340 | 322 | 48.1 |

| 67 | 33.3 | 50.2 | 76.8 | 53.6 | 35.2 | 330 | 313 | 47 | |

| 66.4 | 107 | 32.2 | 49.4 | 76.2 | 52.3 | 33.9 | 320 | 303 | 45.8 |

| 65.8 | 31.6 | 48.4 | 75.8 | 51.8 | 32.8 | 310 | 294 | 44.6 | |

| 65.2 | 105.5 | 29.8 | 47.5 | 74.9 | 50.2 | 31.1 | 300 | 284 | 43.4 |

| 64.8 | 29.2 | 47.1 | 74.6 | 49.7 | 30.4 | 295 | 280 | 42.8 | |

| 64.5 | 104.5 | 28.5 | 46.5 | 74.2 | 49 | 29.5 | 290 | 275 | 42.2 |

| 64.2 | 27.8 | 46 | 73.8 | 48.4 | 28.7 | 285 | 270 | 41.6 | |

| 63.8 | 103.5 | 27.1 | 45.3 | 73.4 | 47.8 | 27.9 | 280 | 265 | 40.9 |

| 63.5 | 26.4 | 44.9 | 73 | 47.2 | 27.1 | 275 | 261 | 40.3 | |

| 63.1 | 102 | 25.6 | 44.3 | 72.6 | 46.4 | 26.2 | 270 | 256 | 39.7 |

| 62.7 | 24.8 | 43.7 | 72.1 | 45.7 | 25.2 | 265 | 252 | 39 | |

| 62.4 | 101 | 24 | 43.1 | 71.6 | 45 | 24.3 | 260 | 247 | 38.4 |

| 62 | 23.1 | 42.2 | 71.1 | 44.2 | 23.2 | 255 | 243 | 37.8 | |

| 61.6 | 99.5 | 22.2 | 41.7 | 70.6 | 43.4 | 22.2 | 250 | 238 | 37.2 |

| 61.2 | 21.3 | 41.1 | 70.1 | 42.5 | 21.1 | 245 | 233 | 36.5 | |

| 60.7 | 98.1 | 20.3 | 40.3 | 69.6 | 41.7 | 19.9 | 240 | 228 | 35.9 |

| 96.7 | 18 | 230 | 219 | 34.1 | |||||

| 95 | 15.7 | 220 | 209 | 33.2 | |||||

| 93.4 | 13.4 | 210 | 200 | 31.8 | |||||

| 91.5 | 11 | 200 | 190 | 30.4 | |||||

| 89.5 | 8.5 | 190 | 181 | 29 | |||||

| 87.1 | 6 | 180 | 171 | 27.7 | |||||

| 85 | 3 | 170 | 162 | 26.5 | |||||

| 81.7 | 0 | 160 | 152 | 25 | |||||

| 78.7 | 150 | 143 | 23.7 | ||||||

| 78 | 140 | 133 | 22.1 | ||||||

| 71.2 | 130 | 124 | 20.6 | ||||||

| 66.7 | 120 | 114 | 19.1 | ||||||

| 62.3 | 110 | 105 | 17.6 | ||||||

| 56.2 | 100 | 95 | 16.1 | ||||||

| Rockwell hardness | Surface Rockwell hardness | Vickers hardness | |||

| HRB | HRF | 15T | 30T | 45T | HV |

| 100kgf | 60kgf | 15kgf | 30kgf | 45kgf | 50kgf |

| 93.5 | 110 | 90 | 77.5 | 66 | 196 |

| 109.5 | 65.5 | 194 | |||

| 93 | 77 | 65 | 192 | ||

| 92.5 | 109 | 76.5 | 64.5 | 190 | |

| 92 | 89.5 | 64 | 188 | ||

| 91.5 | 108.5 | 76 | 63.5 | 186 | |

| 91 | 75.5 | 63 | 184 | ||

| 90.5 | 108 | 89 | 62.5 | 182 | |

| 90 | 107.5 | 75 | 62 | 180 | |

| 89 | 74.5 | 61.5 | 178 | ||

| 88.5 | 107 | 61 | 176 | ||

| 88 | 88.5 | 74 | 60.5 | 174 | |

| 87.5 | 106.5 | 73.5 | 60 | 172 | |

| 87 | 59.5 | 170 | |||

| 86 | 106 | 88 | 73 | 59 | 168 |

| 85.5 | 72.5 | 58.5 | 166 | ||

| 85 | 105.5 | 72 | 58 | 164 | |

| 84 | 105 | 87.5 | 57.5 | 162 | |

| 83.5 | 71.5 | 56.7 | 160 | ||

| 83 | 104.5 | 71 | 56 | 158 | |

| 82 | 104 | 87 | 70.5 | 55.5 | 156 |

| 81.5 | 103.5 | 70 | 54.5 | 154 | |

| 80.5 | 103 | 54 | 152 | ||

| 80 | 86.5 | 69.5 | 53.5 | 150 | |

| 79 | 102.5 | 69 | 53 | 148 | |

| 78 | 102 | 68.5 | 52.5 | 146 | |

| 77.5 | 101.5 | 86 | 68 | 51.5 | 144 |

| 77 | 101 | 67.5 | 51 | 142 | |

| 76 | 100.5 | 85.5 | 67 | 50 | 140 |

| 75 | 100 | 66.5 | 49 | 138 | |

| 74.5 | 99.5 | 85 | 66 | 48 | 136 |

| 73.5 | 99 | 65.5 | 47.5 | 134 | |

| 73 | 98.5 | 84.5 | 65 | 46.5 | 132 |

| 72 | 98 | 84 | 64.5 | 45.5 | 130 |

| 71 | 97.5 | 63.5 | 45 | 128 | |

| 70 | 97 | 83.5 | 63 | 44 | 126 |

| 69 | 96.5 | 62.5 | 43 | 124 | |

| 68 | 96 | 83 | 62 | 42 | 122 |

| 67 | 95.5 | 61 | 41 | 120 | |

| 66 | 95 | 82.5 | 60.5 | 40 | 118 |

| 65 | 94.5 | 82 | 60 | 39 | 116 |

| 64 | 94 | 81.5 | 59.5 | 38 | 114 |

| 63 | 93 | 81 | 58.5 | 37 | 112 |

| 62 | 92.6 | 80.5 | 58 | 35.5 | 110 |

| 61 | 92 | 57 | 34.5 | 108 | |

| 59.5 | 91.2 | 80 | 56 | 33 | 106 |

| 58 | 90.5 | 79.5 | 55 | 32 | 104 |

| 57 | 89.8 | 79 | 54.5 | 30.5 | 102 |

| 56 | 89 | 78.5 | 53.5 | 29.5 | 100 |

| 54 | 88 | 78 | 52.5 | 28 | 98 |

| 53 | 87.2 | 77.5 | 51.5 | 26.5 | 96 |

| 61.6 | 86.6 | 77 | 50.5 | 24.5 | 94 |

| 49.5 | 85.4 | 76.5 | 49 | 23 | 92 |

| 47.5 | 84.4 | 75.5 | 48 | 21 | 90 |

| 46 | 83.5 | 75 | 47 | 19 | 88 |

| 44 | 82.3 | 74.5 | 45.5 | 17 | 86 |

| 42 | 81.2 | 73.5 | 44 | 14.5 | 84 |

| 40 | 80 | 73 | 43 | 12.5 | 82 |

| 37.5 | 78.6 | 72 | 41 | 10 | 80 |

| 35 | 77.4 | 71.5 | 39.5 | 7.5 | 78 |

| 32.5 | 76 | 70.5 | 38 | 4.5 | 76 |

| 30 | 74.8 | 70 | 36 | 1 | 74 |

| 27.5 | 73.2 | 69 | 34 | 72 | |

| 24.5 | 71.6 | 68 | 32 | 70 | |

| 21.5 | 70 | 67 | 30 | 68 | |

| 18.5 | 68.5 | 66 | 28 | 66 | |

| 15.5 | 66.8 | 65 | 25.5 | 64 | |

| 12.5 | 65 | 63.5 | 23 | 62 | |

| 10 | 63 | 62.5 | 20.5 | 60 | |

| 61 | 61 | 18 | 58 | ||

| 58.8 | 60 | 15 | 56 | ||

| 56.5 | 58.5 | 12 | 54 | ||

| 53.5 | 57 | 52 | |||

| 50.5 | 55.5 | 50 | |||

| 49 | 54.5 | 49 | |||

| 47 | 53.5 | 48 | |||

| 45 | 47 | ||||

| 43 | 46 | ||||

| 40 | 45 | ||||

Note: When considering cutting processing, a general conversion of 1HRC ≈ 10HB applies (the hardness of the workpiece material may vary slightly).

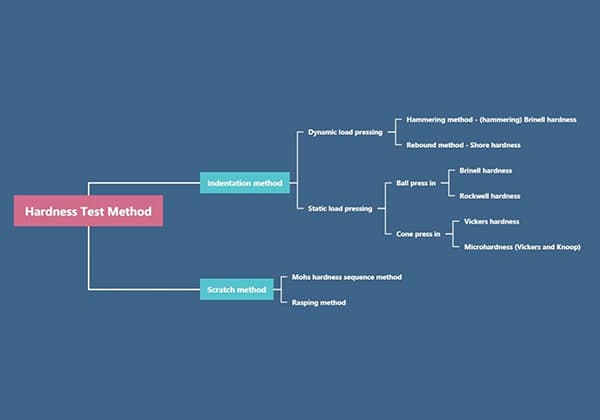

The most commonly used indentation hardness tests for metal materials are Brinell, Rockwell, and Vickers hardness tests.

The hardness value indicates a material’s ability to resist plastic deformation caused by the intrusion of another object.

When measuring hardness using the rebound method, the hardness value represents the extent of the metal’s elastic deformation function.

Hardness is a metric that measures a material’s resistance to local deformations, such as plastic deformation, indentations, or scratches.

It is a crucial factor in determining the hardness of a material.

According to the different test methods, there are three types of hardness.

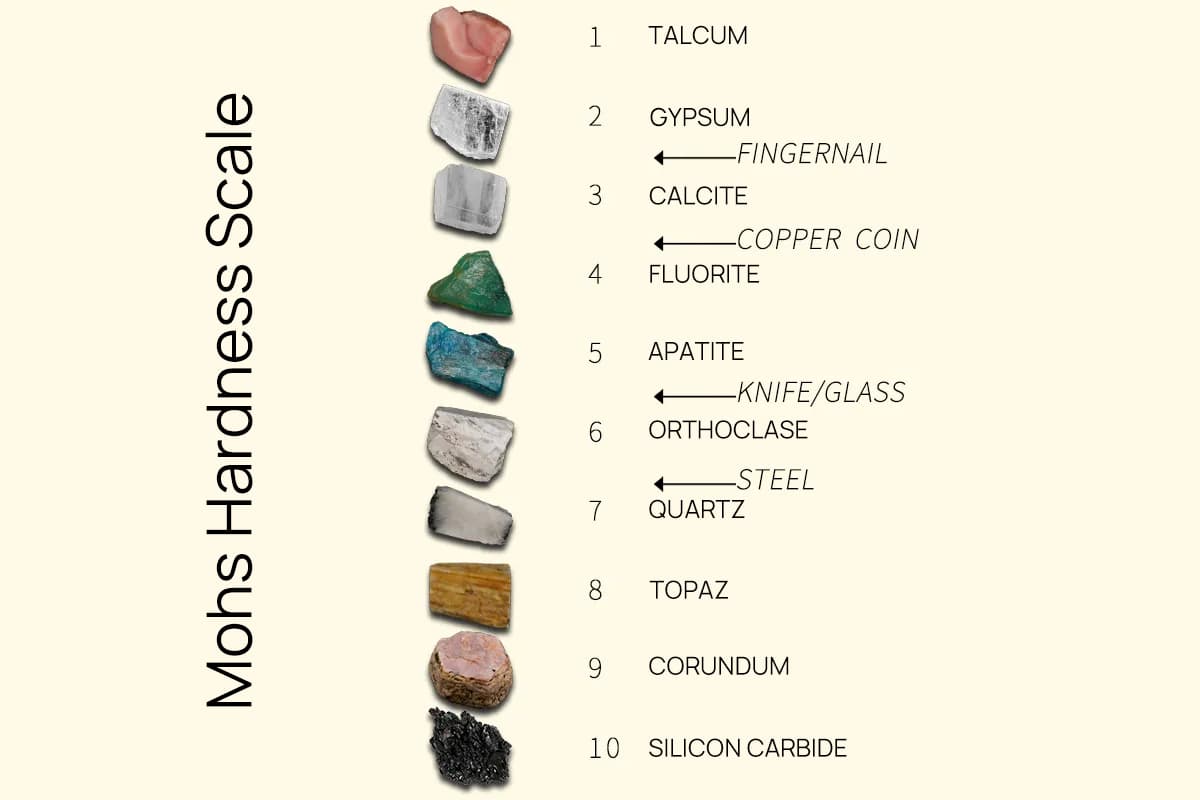

① Scratch hardness

Hardness is primarily utilized to compare the resistance to local deformation of various minerals.

The process involves using a rod with a hard and soft end to test the material by sliding it along the rod.

The material’s softness or hardness is determined based on the length of the scratch it leaves on the rod.

Typically, scratches made by harder materials are longer and those made by softer materials are shorter.

② Indentation hardness

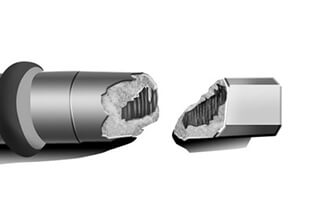

Indentation hardness testing is primarily used to evaluate metal materials. It involves applying a specified indenter to the surface of the material under test with a specific load.

The material’s hardness is determined by comparing the amount of local plastic deformation on the material’s surface.

There are several types of indentation hardness tests, including Brinell hardness, Rockwell hardness, Vickers hardness, and micro-hardness, which differ in terms of the indenter used, the applied load, and the duration of the load.

③ Rebound hardness

Rebound hardness testing is primarily used for metal materials. The method involves using a special small hammer that is dropped from a specific height to impact the material sample being tested.

The material’s hardness is determined by the amount of strain energy stored in and then released from the sample during the impact, which is measured by the rebound height of the hammer.