Have you ever struggled with a plasma cutter that just won’t strike an arc? As an experienced mechanical engineer, I’ll share insider tips to troubleshoot this frustrating issue. From voltage instability to air pressure problems, we’ll dive into the common culprits behind arc failure and provide practical solutions to get your plasma cutter back in action. Get ready to master the art of plasma cutting and achieve flawless results every time!

Various factors may cause a plasma cutting machine not to generate an arc.

Firstly, voltage instability is a common issue, as plasma power sources typically need to be connected to a three-phase 380V voltage. Phase absence or inadequate voltage capacity can result in an inability to strike an arc. Secondly, air intake issues are another significant factor.

Lack of intake or insufficient air pressure can affect the normal arc initiation of the plasma cutting machine.

Solutions to these problems include checking the power supply, replacing the contactor, repairing the internal wiring, and closely monitoring the air compressor’s output pressure display to ensure sufficient pressure.

If you encounter issues with inadequate air pressure, it may be due to insufficient air input from the air compressor, too low pressure regulation by the air regulator valve, blockages in the solenoid valve, or a non-smooth air path.

Therefore, addressing the issue of a plasma cutting machine not generating an arc requires considering all these possibilities and taking appropriate measures.

The stability of the arc in an NC plasma cutting machine is crucial for the quality of the cuts produced.

If the plasma arc is unstable, it can lead to problems such as uneven cuts, the buildup of edges, decreased performance of the control system components, and the need for frequent replacements of nozzles and electrodes.

Based on the analysis of this phenomenon, the solutions proposed are as follows:

If the input air pressure exceeds 0.45Mpa, it can have a negative impact on the plasma cutting process.

The excessive airflow will cause the plasma arc to disperse, weakening the concentration and intensity of the arc column, and reducing its cutting power.

Causes of high air pressure include:

The solution to the problem is:

When using a plasma cutting machine, if the working pressure is significantly lower than the required pressure specified in the specifications, this can negatively impact the cutting quality.

A low working pressure means a weakened plasma arc ejection speed and reduced input airflow, which will prevent the formation of a high-energy and high-speed plasma arc.

This can result in poor cutting quality, incomplete cuts, and the buildup of unwanted material on the cutting edge.

The causes of low air pressure include:

The solution to the problem is:

Before operating the plasma cutting machine, it is crucial to inspect the air compressor’s output pressure display and make any necessary adjustments.

If the air pressure input meets the required standards, it is equally important to confirm that the air filter pressure relief valve is properly adjusted and the pressure display meets the plasma cutting requirements.

Proper maintenance of the air filter pressure relief valve must be performed regularly to guarantee the input air is clean and oil-free.

Contaminated air can cause oil buildup in the solenoid valve, making it challenging to open the valve core and leading to an insufficiently opened valve port.

When the torch nozzle pressure is too low, replacing the electromagnetic valve may be necessary.

A reduction in the gas channel cross-section can also lead to low air pressure. In such cases, the air tube can be replaced following the provided instructions.

Proper grounding is an essential step before using a plasma cutting machine.

If the appropriate grounding tool is not utilized, or if the workpiece surface is not properly grounded, the connection between the ground wire and the workpiece will be weak.

It is advisable to use specialized grounding tools to detect any insulation that could negatively impact the connection between the ground wire and the workpiece surface.

Using worn or old ground wires should be avoided.

The causes of premature damage of nozzle:

The solution to the problem is:

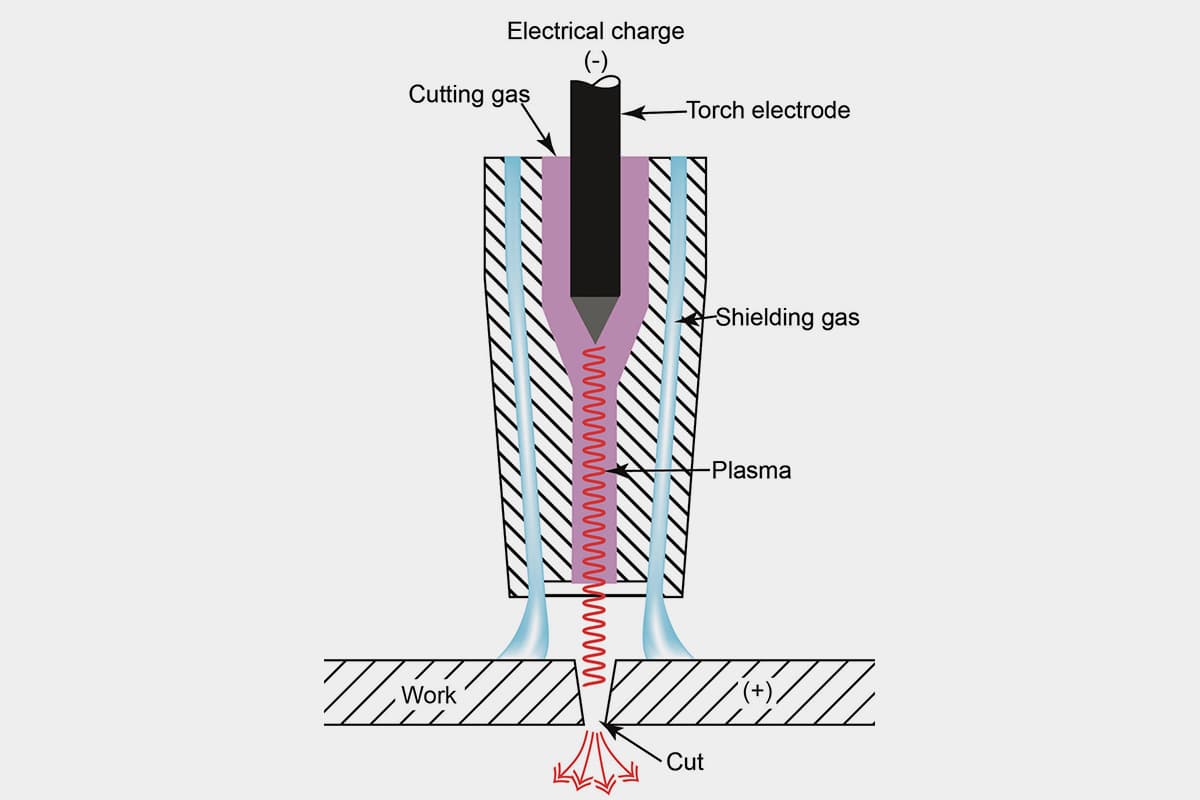

When the plasma cutting machine is in use, the first step is to ignite the plasma arc.

The high-frequency oscillator triggers the gas between the electrode and the nozzle’s inner wall to form a high-frequency discharge that partially ionizes the gas and creates a small arc.

This small arc is then expelled from the nozzle by the compressed air, igniting the plasma arc.

This is the main function of the spark generator.

Typically, the spark generator operates for only 0.5 to 1 second.

If the arc cannot be automatically broken, it is usually because the components of the control circuit board are imbalanced or the gap between the spark generator’s discharge electrode is not set optimally.

The solution to the problem is:

There are significant electrical facilities located on the site where the plasma cutting machine is used.

The malfunction of critical circuit components in the plasma cutting machine can result in an input AC voltage that is insufficient.

To address this problem, the following steps should be taken:

It is important to verify that the power grid connected to the plasma cutting machine has adequate load capacity and complies with the necessary power line specifications.

The plasma cutting machine should be located in a place that is distant from large electrical equipment and areas with electrical interference.

It is recommended to regularly clean dust and debris from components within the plasma cutter and check for worn wires during use.

Aside from the previously mentioned causes, the stability of the plasma arc can also be impacted by factors such as a cutting speed that is too slow, the angle of the cutting torch in relation to the workpiece, and the operator’s level of expertise in using the plasma cutter. It is essential for users to keep these factors in mind.

Firstly, it’s crucial to check if the power supply of the plasma cutting machine is operating normally, ensuring the voltage is stable.

In addition, the grounding of the plasma cutting machine should be inspected to confirm it’s well-grounded. This is because proper grounding can enhance the stability of arc initiation.

On-site, if there are large power-consuming facilities or internal main circuit component failures within the cutting machine, it may result in an excessively low input AC voltage. Therefore, it’s necessary to inspect these situations.

Lastly, further assurance of voltage stability can be achieved by checking the voltage detector or motor regulator for proper functioning. Through these steps, we can more accurately detect and ensure the voltage stability of the plasma cutting machine.

The common issues with the air intake system of a plasma cutting machine primarily include solenoid valve malfunctions, improper air pressure adjustments, insufficient air pressure, interrupted or inadequate gas supply, and intake blockage or moisture. The solutions to these issues are as follows:

Solenoid Valve Issues: If the plasma cutter isn’t emitting air, the intake solenoid valve should be checked for damage. If the valve is faulty, it needs to be replaced.

Improper Air Pressure Adjustment: Check the air pressure adjustment filter on the back panel of the air plasma cutter, ensuring that the air pressure is neither too high nor too low. Generally, the air pressure should be maintained at about 0.35MPa to ensure the normal formation and arcing of the plasma.

Insufficient Air Pressure: Causes for insufficient air pressure might include inadequate air input from the air compressor, excessively low pressure adjustment of the cutting machine’s air control valve, oil contamination inside the solenoid valve, or an obstructed air path. The solution is to monitor the output pressure of the air compressor before use, adjust the air control valve’s pressure setting as needed, clean the oil contamination inside the solenoid valve, and ensure an unobstructed air path.

Interrupted or Insufficient Gas Supply: Check and reconnect the gas pipeline, increase gas pressure to ensure the continuity and adequacy of the gas supply.

Intake Blockage or Moisture: If the intake is blocked or slightly damp, it needs to be cleaned or replaced to ensure smooth entry of gas into the interior of the cutting machine.

To determine if the input air pressure of a plasma cutter is appropriate, you first need to understand the air pressure range required for the normal operation of a plasma cutter. According to various sources, the air pressure of an air plasma cutter is generally adjusted between 0.4~0.6MPa, but it is also suggested to adjust the back pressure to 0.2-0.3MPa according to the actual situation.

This indicates that the specific requirements for air pressure may vary depending on the type, thickness of the cutting material, and the cutting speed.

In practical operations, if you encounter situations where the arc does not cut or the cutting effect is poor, it may be due to inappropriate input air pressure.

For example, if the input air pressure is significantly lower than the normal range, it may cause the arc not to start. Therefore, checking the air compressor’s output pressure display to ensure it meets the requirement is an important step in determining whether the air pressure is appropriate.

Also, pay attention to whether the adjustment of the air filter pressure reducer is correct and whether there are any failures, which could cause the air pressure to be too high or too low.

The appropriateness of the input air pressure of a plasma cutter can be determined through the following steps:

By following these steps, you can accurately determine whether the input air pressure of a plasma cutter is appropriate, thus ensuring the smooth progress of the cutting process.

What are the common causes of damage to the plasma cutter torch and electrode, and what is the guide for their replacement?

These factors can severely affect the function of the plasma system, leading to damage to the torch and electrode.

Regarding the replacement guide, the first step is to turn off the plasma cutter and disconnect the power supply to ensure the equipment is in a safe state.

Then, based on the instructions in the equipment manual, determine the type and location of the consumable parts that need to be replaced, and use appropriate tools such as wrenches and screwdrivers for gentle disassembly.

Consumables like electrodes and nozzles that are prone to wear should be replaced regularly for efficient cutting. During the replacement process, you can consider replacing the entire machine torch and cable assembly, or replace individual components. In addition, using a clean lint cloth to wipe the inside of the nozzle can eliminate oxides, which is an important measure to prevent torch damage.