Ever wonder why your press brake isn’t descending in sync? This article dives into the common causes of desynchronization in hydraulic press brakes, such as internal leakage in the piston cylinder and issues in the oil pipeline. It also offers practical solutions, ensuring your machine operates smoothly and efficiently. Learn how to troubleshoot and fix these issues to maintain the quality and productivity of your metalworking processes.

The WC67Y-250/4000 hydraulic press brake is designed for bending metal sheets with high labor productivity and bending accuracy. It offers stability, reliability, and ease of operation, with inching or continuous travel options.

This hydraulic press brake maintains consistent pressure throughout the entire working stroke, ensuring uniform force distribution. Users can easily equip it with different molds to achieve the required sheet metal bending shape.

However, it’s important to note that the return movement speed of this press brake is several times faster than the bending process, allowing for improved production efficiency. However, it’s crucial to ensure that the cylinder of the press brake doesn’t fall too quickly, causing it to fall out of sync and potentially affecting the quality of the final product.

The primary reason for the issue is internal leakage in the piston cylinder. The gap between the piston and the oil cylinder is too large, causing leakage. However, the leakage in the left and right cylinders is not uniform, resulting in different movement speeds of the two cylinders.

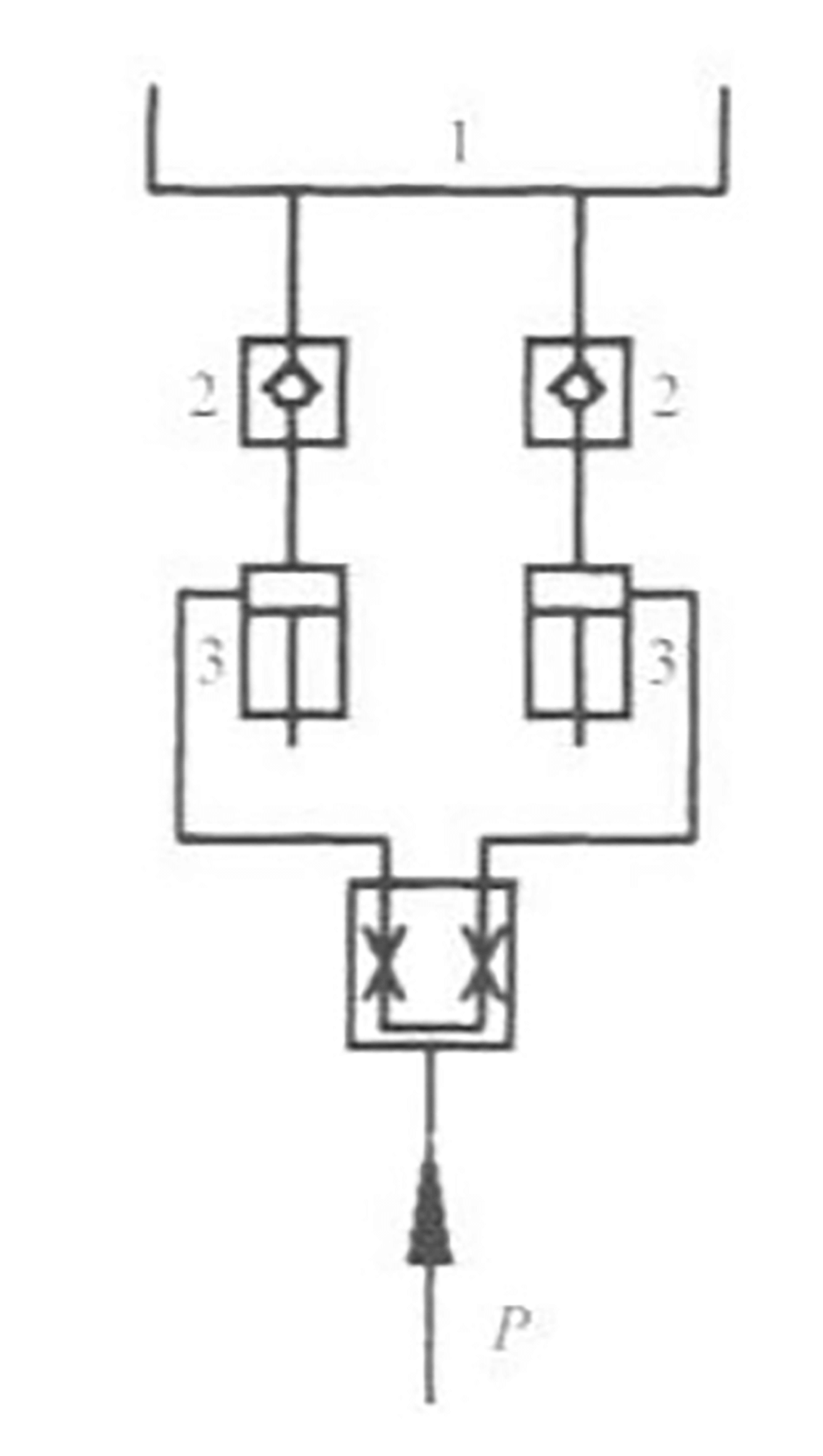

Figure 1 illustrates the process of the press brake descending rapidly. The oil pump supplies oil to the oil cylinder through the synchronous valve, while the top oil tank 1 feeds oil to the oil cylinder through the one-way valve 2 via the natural height difference. These two types of oil supply oil to the upper chamber of the oil cylinder, which causes the oil cylinder to descend rapidly.

Due to the approximate flow in the valve circuit after the synchronization valve, only the flow from the tank through check valve 2 into the oil cylinder 3 is taken into account.

1- Oil tank; 2 – Check valve; 3 – Oil cylinder.

Fig. 1 Oil supply analysis of oil cylinder

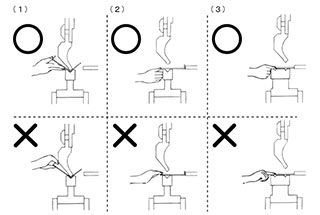

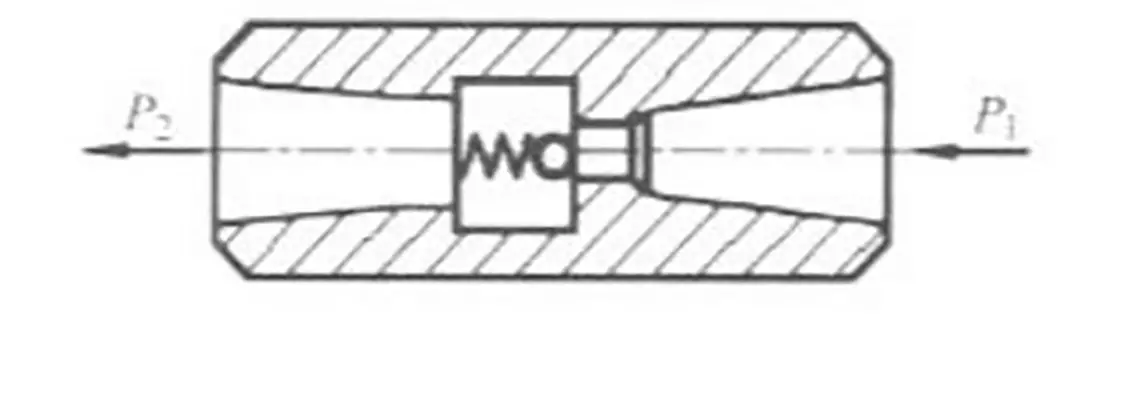

Figure 2 displays the structure of check valve 2.

P1 denotes the inlet pressure while P2 represents the outlet pressure.

Considering the inlet pressure for both check valves, P1 can be considered as atmospheric pressure, making them equal.

Given that P1 is constant, the flow rate Q through the check valve increases with an increase in pressure difference (P-P2).

Fig. 2 Check valve structure

It is evident from the above that the two hydraulic cylinders will not be completely synchronized when started. As a result, the pressure in the upper chamber of the two cylinders, denoted as P, will not be the same. This pressure difference between the front and rear of the two check valves will also not be the same.

Consequently, the flow from the oil cylinder through the one-way valve into the two cylinders will not be equal. This imbalance in flow will result in the movement of the two cylinders being unsynchronized.

When the press brake rapidly descends, the motion damping in the return oil circuit may not be equal, causing a difference in back pressure in the lower chamber of the piston. Consequently, the return flow rate of the two cylinders may not be the same, resulting in the rapid descent speed of the two cylinders being unequal and therefore out of synchronization.

(1) In order to ensure equal leakage in both hydraulic cylinders, it is important to maintain consistency in the selection accuracy of left and right pistons, cylinders, and other parts (including dimensional accuracy and position accuracy such as coaxiality, roundness, etc.). Additionally, the hydraulic circuits of the two hydraulic cylinders should be designed as similarly as possible.

(2) To ensure equal flow through the two check valves in the oil inlet pipeline, it is necessary to strive for the center of gravity of the movable frame to be located at the geometric center of the two cylinders. Additionally, the mechanical damping between the piston and the piston rod, and between the piston rod and the end cover should be as close as possible to ensure similar mechanical damping of the two piston cylinders when they drop rapidly.

(3) For the oil return pipeline, it is necessary to ensure that the return flow of the two cylinders is equal by making the return oil resistance of the oil return pipeline similar. This involves ensuring that the pipe diameter, pipe length, pipe bending number, and pipe bending angle are basically the same.

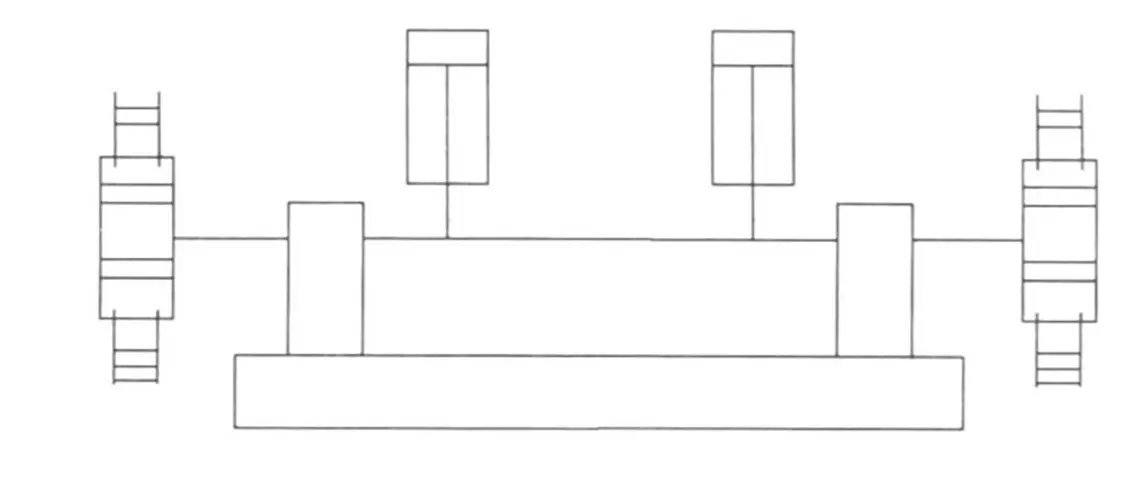

(4) The press brake utilizes a mechanical rack and pinion drive for force synchronization. The device is shown in Figure 3, with the rack installed on both sides of the connecting frame and meshed with the gear on the rack. The rack serves as the guiding device and error correction is made through the gear meshing. As long as the manufacturing accuracy of the rack and gear is guaranteed, the two working cylinders of the press brake can achieve a very high level of synchronous accuracy.

Fig. 3 Schematic diagram of gear rack drive with forced synchronization

Through the collaboration of users, designers, and manufacturers, the entire process of manufacturing, assembly, and commissioning has been significantly improved. As observed in current usage, the structure is simple and compact, and the operation is stable with minimal noise. As a result, the quality of the bent steel plates is ensured, and the bending efficiency meets the required standards.