What makes high-strength bolts so critical in modern engineering? As machines and structures grow more powerful and complex, the demands on bolts increase exponentially. This article delves into the materials and mechanisms behind high-strength bolts, examining their performance under extreme conditions and highlighting the latest advancements. Discover how these bolts are engineered to withstand the highest stresses, ensuring safety and reliability in everything from skyscrapers to automotive engines. Explore the future of bolt materials and what it means for the next generation of engineering challenges.

Abstract: The increasing demands for high-strength bolts, along with their expanding application fields, have led to higher performance requirements for high-strength bolt steel. The steel must not only exhibit high strength but also ensure reliable performance.

This paper explores the current research status, strengthening mechanisms, and commonly used materials for high-strength bolts, and highlights the future trends in their development.

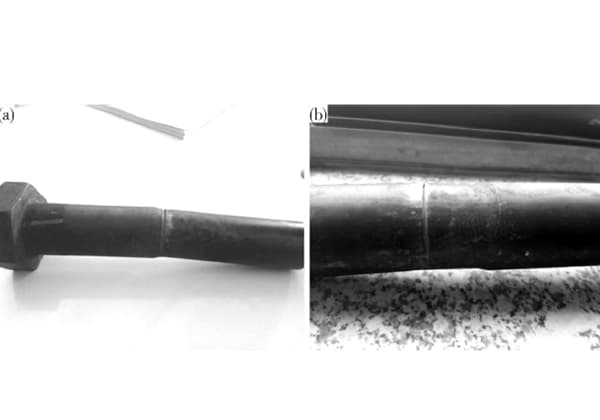

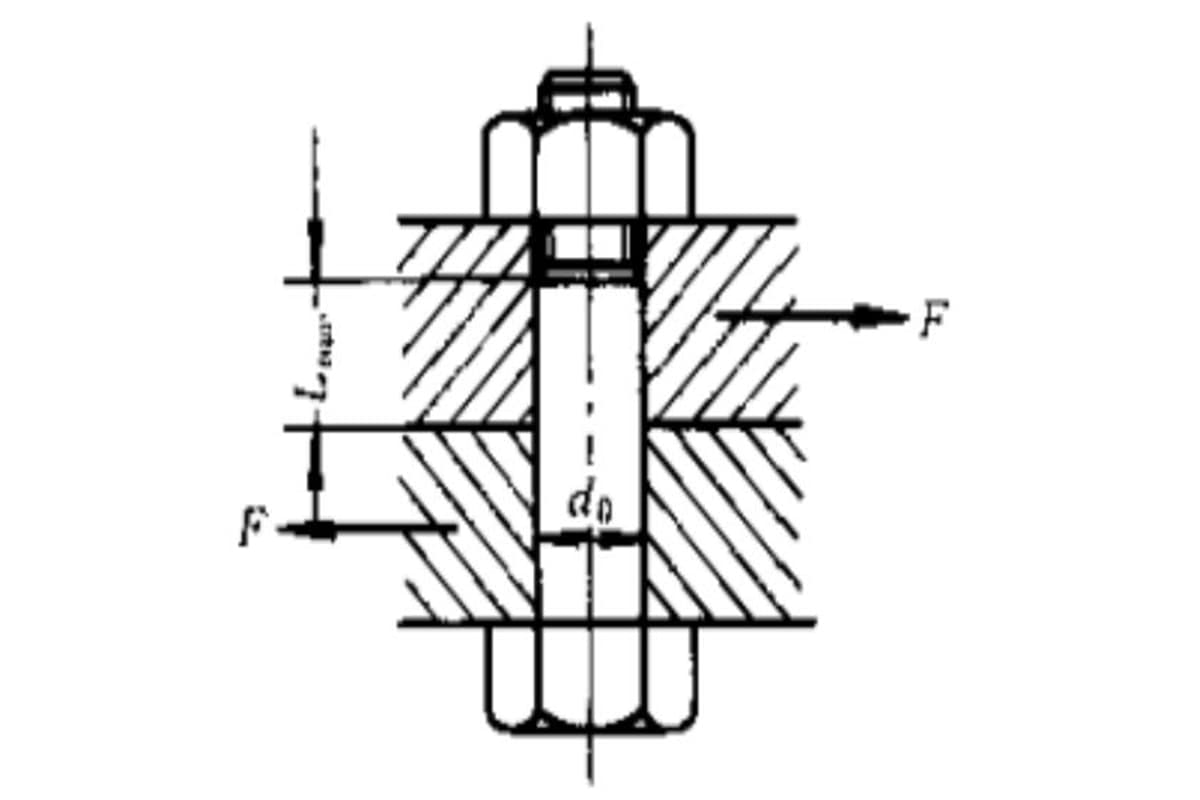

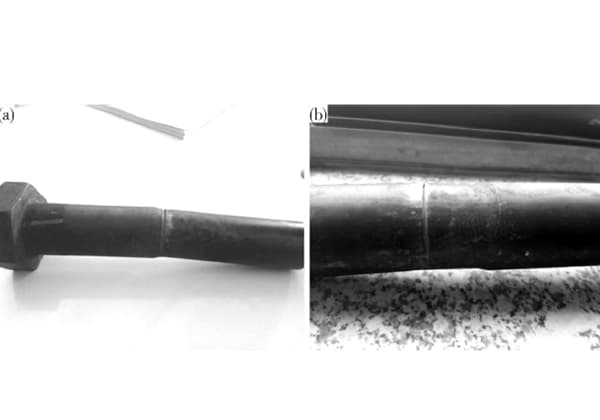

Fasteners, such as bolts, play a critical role in connecting, positioning, and sealing mechanical components. Bolts are the most widely used type of fastener.

As machinery, equipment, and construction projects continue to expand and improve in terms of power and speed, the working conditions and stress levels of bolts have become increasingly demanding. This has resulted in a need for higher strength bolt steel.

For instance, high-pressure feed water pumps used in supercritical and ultra-supercritical generating units require stronger bolts to ensure their sealing and pressure-bearing functions can meet the increasing water supply pressure requirements.

High-strength bolts are also crucial components in the construction of large building grid structures, such as those found in public buildings. These bolts transfer alternating internal forces caused by alternating loads and are directly related to public safety.

The original bolts used in automobiles and motorcycles, especially engine bolts, are struggling to meet the high stress requirements of engines. High-strength bolts can reduce the size and mass of the bolts, which can help reduce vehicle weight and energy consumption.

Additionally, the high strength of bolts contributes to the miniaturization and compactness of other automobile structures.

In conclusion, high-strength bolts have significant practical value and a promising future for a broad range of applications.

The strength levels of high-strength bolts are divided into four categories: 8.8, 9.8, 10.9, and 12.9. Please refer to Table 1 for the mechanical properties of bolts at each level.

Based on the quality of high-strength bolt steel, it can be divided into three categories: current quality, potential quality, and final quality.

Bolts working in humid or corrosive atmospheres must have low delayed fracture sensitivity. Bolts bearing alternating and impact loads must have higher fatigue resistance and multiple impact tensile resistance to resist fatigue and multiple impact fractures. For bolts operating in severely cold areas, low ductile brittle transition temperatures are necessary for bolt materials.

Table.1 Indexes of high strength bolt‘s mechanical properties

| Mechanical properties | Bolt grade | ||||

| 8.8 | 9.81040-1180 | 10.9 | 12.9 | ||

| ≤M16mm | >M16mm | ||||

| Tensile strength/MPa | 800-980 | 830~980 | 32~39 | 1040-1180 | 1220~1380 |

| Rockwell hardness/HRC | 22~32 | 23~34 | 10.9 | 32~39 | 39~44 |

According to the service conditions of high-strength bolts, there are generally the following requirements for their mechanical properties:

The use of high-strength bolts in China is relatively recent. It was first used on some railway bridges in the 1960s and later on boiler steel structures in the 1980s.

In the 1990s, China started to introduce foreign cars and production technologies and discovered bolts with a strength grade of 12.9, tensile strength of 1200 MPa, and yield strength of 1080 MPa. At that time, these bolts were the highest strength level among automotive bolts.

After FAW Group imported the Chrysler 488 engine from the United States, the flywheel bolts were dependent on imports. To achieve localization, FAW Group identified the materials used for flywheel bolts in the United States and the high-strength bolts used for German Audi cars, both of which were equivalent to ML35MnMo and ML35CrMo, respectively, by comparing the composition of foreign high-strength bolt materials with the existing materials in China.

Therefore, ML35CrMo was selected as the material for the domestic trial production of 12.9 grade flywheel bolt material. The decarburized layer on the surface of raw materials was removed by material peeling technology. After cold upset forging and end quenching tests, annealing, quenching and tempering process tests, finished product performance tests, bench tests, and loading tests, high-strength bolts with properties equivalent to those of CA488 engine flywheel bolts were successfully developed.

Wang Rongbin et al. used lath martensite structure to improve the performance of high-strength bolts. They can also obtain high-performance bolts above grade 10.9 and partially replace quenched and tempered high-quality structural steel. Low carbon martensite (lath martensite) steel is widely used for its high strength, plasticity, toughness, and low notch sensitivity.

Taiyuan Iron and Steel Co., Ltd. has developed a series of low carbon martensite fastener steels for the automobile and standard parts industries. For example, ML15MnVB, ML20MnVB, ML15MnB, and ML15Mn are used to make grade 8.8, 9.8, and 10.9 high-strength bolts, which have achieved good results.

Leng Guangrong and his team have successfully controlled the properties of low-carbon medium-alloy steel (22Cr2Ni4MoV) to achieve a tensile strength of 1560 MPa, elongation of 12%, hardness of 45 HRC, and impact energy of 60 J through an appropriate heat treatment process.

However, high-strength bolts made of this material can only barely meet the requirements of the 2500 mm four-high rolling mill for the mechanical properties of bolt materials. Moreover, the average service life of the bolts is only two months, which is not satisfactory in terms of durability.

In order to improve the material’s strength, Pan Zuyi et al. utilized the 22Cr2Ni4MoV material and controlled the chemical composition, structure, and properties through the quenching+low-temperature tempering or quenching+high-temperature tempering heat treatment process. This resulted in the steel’s strength, plasticity, and toughness being well matched.

The newly developed high-strength bolt steel has a long service life for the 2500 mm universal joint bolt of the four-high reversing mill.

However, when the tensile strength exceeds 1200 MPa, the delayed fracture becomes a significant problem. High-strength bolts are notched parts and have high notch sensitivity, making them susceptible to delayed fracture at the notch stress concentration position. As a result, their application scope is limited.

To address this issue, Hui Weijun et al. increased the Mo content and added microalloying elements V and Nb, while reducing Mn and impurity elements P and S content, in the 42CrMo material composition. They developed a high-strength bolt steel ADF1, which has good delayed fracture resistance at the strength level of 1300 MPa.

Further analysis indicates that the grain size of the steel has been refined from about 12 μm to about 5 μm. This refinement, combined with the secondary hardening effect of Mo and V carbides and the cyclic heat treatment, has significantly increased the notch tensile critical stress.

Therefore, it can be concluded that the delayed fracture resistance of high-strength bolts can be improved by adjusting the alloy content, adding corrosion-resistant alloy elements, refining grains, reducing grain boundary segregation, increasing tempering temperature, and neutralizing invading hydrogen.

Thanks to these measures, the ADS series from Sumitomo Metal, the KNDS series from Kobe Iron, and the ADF series from China Iron and Steel Research Institute have successfully developed high-strength bolt steel with good delayed fracture resistance.

However, compared to developed countries, the research and development level of high-strength bolt steel in China is still relatively backward. Currently, only materials such as ML20MnVB, ML35CrMoV, and 35CrMo can meet the requirements for 12.9 grade high-strength bolts.

In 2005, China was still importing the 12.9 grade connecting rod bolts used in automobile engines due to the lack of domestically produced high-strength bolt steel.

Although Hui Weijun and others have developed a 1300 MPa high-strength bolt material, 42CrMoVNb, based on 42CrMo, its performance in practical applications needs further investigation.

The material properties required for high-strength bolts vary according to the service environments.

Yang Xinglin and his colleagues discovered that the 35CrMnSiA material used for high-strength bolts in the marine environment is prone to fracture during service.

Analysis revealed that the fracture of the bolt was not due to ordinary hydrogen embrittlement, but to stress corrosion caused by the severe corrosion of the marine atmosphere and seawater on the bolt materials.

It was suggested that replacing the coating and improving the detection level of finished products would enhance the bolt’s resistance to stress corrosion cracking, but the problem of material performance defects remained unresolved.

After considering the service environment, Fang Dong and his team chose 16Co14Ni10Cr2Mo material to replace 35CrMnSiA.

This steel boasts high strength, good plasticity, toughness, and excellent overall performance.

While it has been widely used in aviation, this is the first time it is being utilized for manufacturing large section bolts and being applied in the marine environment.

The simulated marine environment test has shown that the M56 bolt made of 16Col4Nil0Cr2MoE steel does not break due to low-temperature brittleness or notch brittleness. Furthermore, stress corrosion cracking and overload fracture do not occur in the pre-tightening state, even if the coating is worn, and normal operation does not cause overload fracture.

The bolt product is safely applicable for one year in practical use. The study of Chinese scholars on high-strength bolts has focused on the hydrogen embrittlement fracture mechanism, improvement of the heat treatment process, and failure analysis of high-strength bolts. This research provides a crucial foundation for the development of high-strength bolt materials in the future.

The performance of high-strength bolt materials heavily relies on the alloy and trace elements. Research has shown that adding microalloying elements, such as 0.02% Ti, to non-quenched and tempered steel can precipitate a phase that prevents grain growth during heating and hot working, and strengthens the matrix during cooling, improving the overall properties of steel.

However, not all precipitates enhance the comprehensive properties of steel. Using Thermo scale and Dicta software, the precipitation in microalloyed steel 40MnV was calculated.

The composition, morphology, and distribution of the precipitates were studied through electrolytic analysis, X-ray diffraction, and transmission electron microscopy. The results indicate that a small amount of N and Ti in the steel can cause the precipitation of coarse TiN particles, 50 nm in size, in the solid-liquid two-phase zone.

Gladman’s theory suggests that (Ti, V) (C, N) particles precipitated in the solid-liquid two-phase zone cannot prevent grain growth during heating. Instead, these coarse particles harm the steel’s properties.

By reducing the content of N or Ti, the precipitation temperature and quantity of TiN in the solid-liquid two-phase zone can be effectively reduced, ensuring more VN precipitation. About 0.02% Ti in microalloyed steel should be reduced to an appropriate range, and the N content should also be controlled in the appropriate range.

By studying the influence of alloy elements on the properties of materials, we can establish a basis for developing new high-strength bolt materials. However, a proper alloy composition alone cannot guarantee that the developed bolts will meet the actual performance requirements. Only through a reasonable heat treatment process and coordination of material hardness, strength, plasticity, and toughness can bolts with excellent performance be developed.

30NCD16 is a high-strength alloy steel with robust heat resistance and high strength and toughness after medium-high temperature tempering. Liu Xiangjiang and Liu Hua studied the influence of quenching and tempering temperature on the structure and properties of 30NCD16.

They determined that the optimal heat treatment process for the high-strength steel 30NCD16 is between 840 and 870 ℃. After quenching and tempering at 560 ℃, a fine and uniform sorbite structure can be obtained. The tensile strength of the steel is greater than 1200 MPa, and the impact energy Akus is greater than 50 J.

Wang Genji et al. studied the effect of different heat treatment processes on the microstructure and mechanical properties of Q390 low-alloy, high-strength steel thick plate using microstructure observation and mechanical property measurement.

The results show that normalizing at 920 ℃ for 36 min can fully austenitize the mixed crystal structure in the hot-rolled Q390 low-alloy, high-strength steel plate, achieving grain refinement. Subsequent cooling transforms it into polygonal ferrite and pearlite, resulting in excellent comprehensive mechanical properties.

The elongation and impact toughness of CrNiMoBNb16-16 steel are significantly higher than those in the hot rolled state, and the tensile fracture delamination phenomenon is completely eliminated. This high alloy steel is an important material for industrial production, primarily used as bolt material in applications requiring high temperature strength, such as steam turbines, gas turbines, engines, chemical reactors, and high-pressure thermal equipment.

He Wei et al. analyzed the relationship between the structure and mechanical properties of CrNiMoBNb16-16 steel from two perspectives: the influence of heat treatment processes on tensile properties at room and high temperatures and the influence of test temperature on tensile properties.

The test results indicate that with the increase of test temperature (20 ~ 650 ℃), the strength and plasticity of the material decrease significantly. For this material, warm forging exhibits better comprehensive performance than high temperature forging. Consequently, warm forging is determined to be the optimal thermomechanical treatment for this material, resulting in the best match of strength and toughness.

For most alloy structural steels, the tensile strength can be increased to 1200MPa by adjusting the alloy composition and performing proper heat treatment. However, further increasing the strength may reduce the material’s use value and cause greater insecurity due to delayed fracture.

The results show that delayed fracture resistance of high strength steel can be improved by reducing grain boundary segregation, refining grains, increasing tempering temperature, adjusting alloying elements, reducing the amount of hydrogen intrusion on the surface, and making the hydrogen intrusion harmless.

Low alloy steels typically contain a medium amount of carbon. The alloy composition includes Cr, Cr Mo, Cr Ni, Ni Cr Mo, Mn, and Mn Cr series.

Table 2 shows that low alloy bolt steel has a wide range of applications, and the strength grade can be selected from 700 to 1000 MPa.

However, when the strength exceeds 1200 MPa, the problem of delayed failure of bolts made of low alloy steel becomes prominent and needs to be addressed.

Currently, low alloy steel is still the main high-strength bolt material.

Bolts made of low alloy steel require quenching and tempering, meaning they must first be quenched and then tempered.

Moreover, due to the high carbon and alloy element content, the steel has high hardness and deformation resistance.

Therefore, spheroidizing annealing treatment is necessary before cold forging.

Since low alloy steel contains various alloy elements, finding ways to save the alloy in bolt steel and reduce costs is a critical issue to consider.

Additionally, due to the relatively high carbon and alloy element content, the plasticity and toughness of the steel are poor.

To further enhance the strength and ensure necessary plasticity, this issue requires further research.

Tab.2 Some bolt steels’ strength grade MPa

| Type of Steel | 400 | 500~600 | 700~800 | 900~1000 | 1100 |

| carbon steel | √ | √ | √ | ||

| non-quenched and tempered steel | √ | ||||

| boron steel | √ | √ | √ | ||

| low-alloy steel | √ | √ | √ |

With the development of cold forging technology, there has been a significant increase in the demand for cold forging bolt steel.

High-strength bolts were traditionally made of medium carbon steel and medium carbon alloy steel. However, these steels have high hardness and significant cold deformation resistance, requiring spheroidizing annealing treatment before cold forging. This process consumes a lot of energy.

To address this issue, low-carbon boron steel has been developed. The basic principle of the low carbon boron steel composition design is to reduce the carbon content and improve the cold deformation ability of the steel. A small amount of boron is added to compensate for the loss of strength and hardenability caused by carbon reduction. Additionally, small amounts of Cr, Mn, and other alloy elements can be added as required to further improve the hardenability.

The characteristics of low carbon boron steel are as follows:

Boron steel bolts have been increasingly used in the automobile, construction, machinery, and other industries. As Table 2 illustrates, bolts with strength ranging from 700 MPa to 1100 MPa can be made of boron steel.

Non-quenched and tempered steel contains a small amount of alloy elements and does not require quenching and tempering. By controlling the hot working deformation and subsequent cooling rate, the necessary mechanical properties can be ensured, saving energy consumption for heat treatment, shortening the production cycle, and reducing the cost of steel.

Currently, non-quenched and tempered steel bolts are mainly used in automobile manufacturing, but their total number is still small, and their application scope is not wide. Although their cost is lower than that of quenched and tempered steel, their toughness is lower, the strength level is not stable enough, and the die life is shorter during cold forging. These limitations restrict the application scope of non-quenched and tempered steel.

Non-quenched and tempered steel is mainly used for bolts of 700-800 MPa grade, and sometimes for bolts above 900 MPa grade. Typically, non-quenched and tempered C-Mn systems with a carbon content of about 0.25% or C-Mo systems with a carbon content of about 0.10% are used for bolts of 700-800 MPa grade. Trace amounts of Nb, V, Ti, and other elements are added, and the structure is ferrite+pearlite.

When the strength level is above 900 MPa, Cr, Ti, B, and other elements are usually added to the C-Mo Si system containing about 0.10% carbon to improve hardenability and ensure satisfactory strength and toughness. The structure is ferrite+bainite.

To improve the toughness of non-quenched and tempered steel and achieve a well-matched strength and toughness, adjusting the processing technology (such as hot working temperature, rolling deformation, and controlled cooling after rolling) in addition to controlling the chemical composition can also be a solution.

All unalloyed steel (carbon steel) or low-carbon low-alloy structural steel with a carbon content of less than 0.25% can obtain over 80% and sometimes even 100% low-carbon martensite structure after intensive quenching.

This type of steel is commonly referred to as low-carbon martensite steel. It has a hardness of 45-50 HRC, a yield strength of 1000-1300 MPa, and a tensile strength of 1200-1600 MPa.

It exhibits good plasticity (A ≥ 10%, Z ≥ 40%) and toughness (Axv ≥ 59 J), along with excellent cold workability, weldability, and minimal heat treatment distortion.

As a result, the use of low-carbon martensite steel is increasingly widespread, and it has become a crucial way to unlock the strength and toughness potential of steel and extend the lifespan of machine parts.

Materials commonly utilized in the production of high-strength bolts include 15MnVB, 20MnSi, 20 steel, 20MnTiB, and so on.

The mechanisms that strengthen and toughen high-strength steel mainly include fine-grain strengthening, solution strengthening, precipitation and dispersion strengthening, and dislocation strengthening.

1) Fine grain strengthening.

By increasing the grain boundaries to obstruct dislocation movement and restricting plastic deformation within a certain range, it is possible to improve the plasticity of steel. This not only effectively enhances strength but also significantly optimizes plasticity and toughness.

Currently, the technology of controlled rolling and controlled cooling (TMCP) is widely used in the industry. It involves refining the final structure through austenite recrystallization, deformation-induced ferrite transformation (DIFT), accelerated cooling, and ferrite recrystallization.

2) Solution strengthening

The metal matrix (solvent metal) can be strengthened by utilizing the internal point defects of metal materials, such as interstitial atoms and replacement atoms.

As the difference in atomic diameters increases, the degree of distortion also increases, which leads to a greater strengthening effect.

Furthermore, adding elements such as Mn, Si, Ni, Mo to Fe can cause displacement-type solid solution strengthening.

3) Precipitation and dispersion strengthening

When particles of the second phase precipitate, they create a stress field and a high-energy region in the matrix, resulting in a sharp increase in strength, hardness, and overall strengthening.

It can be concluded that:

4) Dislocation strengthening

It is challenging to move dislocations due to their high density.

One mechanical property of metals is improved strength. Dislocation multiplication can strengthen actual metals with crystal defects.

The movement of dislocations is the main reason for solution strengthening, fine grain strengthening, precipitation, and dispersion strengthening.

The micro defects of the matrix structure, including grain boundaries, precipitation particles, dislocation substructure, and solution distortion, mainly affect the strength and toughness of high-strength bolt materials.

The above-mentioned micro defect structures can improve the strength of steel. However, while an increase in grain boundaries (i.e., fine grain strengthening) can increase toughness, other micro defect structures can reduce toughness.

To strengthen high-strength bolt materials, it is necessary to fully utilize these strengthening mechanisms.

With the advancement of energy, automobile, machinery, construction, light industry, and other sectors, there is a growing demand for materials to produce various types of fastening bolts, leading to an urgent need for high-strength bolt materials.

Over the past decade, significant emphasis has been placed on the advancement of this technology both domestically and internationally. In China, the “Major basic research on new generation steel materials” project (973) has been initiated, which includes high-strength bolt steel research and development as one of its critical areas.

The development trend of high-strength bolt steel can be summarized as follows:

1) High strength and high performance steel

With the increase in steel strength, its susceptibility to delayed fracture also increases. Specifically, when the tensile strength exceeds 900 MPa and the hardness is equal to or greater than 31 HRC, the sensitivity to delayed fracture gradually increases. In addition, the greater the service stress, the more extensive the damage caused by fracture.

For this reason, it is crucial to develop high-strength bolt steel with exceptional resistance to delayed fracture. Doing so will help safeguard people’s lives and property, while also expanding the range of applications for high-strength bolts.

2) Reduce cost and energy consumption

To reduce costs, consider substituting cheap boron steel for high-priced alloy steel containing Ni, Cr, Mo, etc.

In addition, the following techniques can help reduce energy consumption, improve yield of bolts, and minimize decarburization tendency of thread tips:

3) Improving the quality and reliability of bolt steel

The reliability and service life of bolt parts are closely related to the metallurgical quality and surface condition of bolt steel, as well as some processing properties.

By increasing the purity of steel and reducing the content of S and P, the deformation ability of steel can be improved. This reduces grain boundary embrittlement and the presence of non-metallic inclusions, thereby enhancing the toughness and plasticity of steel. It also improves the delayed fracture resistance of steel.

Moreover, the manufacturing accuracy, fastening technology, and testing methods of finished bolts are crucial factors that affect the reliability of high-strength bolts.