Have you ever wondered what sets high-strength bolts apart from ordinary ones? High-strength bolts are engineered to handle extreme loads using static friction, making them essential in construction and machinery where durability and safety are paramount. This article explains their unique design, differences from regular bolts, and why they are crucial for robust and resilient structures. Discover how these bolts contribute to enhanced performance and reliability in demanding applications.

The Ultra High-Strength Friction Grip Bolt can reduce weight and increase installation space by decreasing its own size while maintaining the same clamping force. This optimization of function and volume in the connected parts leads to an overall reduction in equipment weight and an improvement in performance.

What is a High-Strength Friction Grip Bolt, you may ask? Allow me to explain.

Physical fasteners of grade 16.8 and 19.8

A High-Strength Bolt is also known as a High-Strength Friction Grip Bolt, abbreviated as HSFG. In construction, the term “High-Strength Bolt” is often used as an abbreviation for “High-Strength Friction Grip Bolt.”

However, in daily communication, the words “friction” and “grip” are often omitted, leading to misunderstandings about the basic definition of a High-Strength Friction Grip Bolt among many engineering and technical personnel.

Myth 1:

Bolts with material grade more than 8.8 are “high strength bolts”?

The key difference between high-strength bolts and regular bolts is not the strength of the materials used, but the form of stress they can handle. High-strength bolts are designed to apply preload and use static friction to resist shear, while regular bolts may not have these capabilities.

It is important to note that in British standard specifications, high-strength bolts (HSFG BOLT) refer to grades 8.8 and 10.9 (BS EN 14399 / ASTM-A325 & ASTM-490), while regular bolts include grades 4.6, 5.6, 8.8, 10.9, 12.9, and others (as specified in Table 2 of Clause 11 of BS 3692).

Thus, it becomes clear that material strength is not the sole factor in distinguishing high-strength bolts from regular bolts.

Table2 Strength grade designations of steel bolts and screws

| Strength grade designation | 4.6 | 4.8 | 5.6 | 5.8 | 6.8 | 8.8 | 10.9 | 12.9 |

| Tensile strength Rm min.N/mm2 | 400 | 400 | 500 | 500 | 600 | 800 | 1000 | 1200 |

| Yield stress Re min.N/mm2 | 240 | 320 | 300 | 400 | 480 | – | – | – |

| Stress at permanent set limit R0.2 N/mm2 | – | – | – | – | – | 640 | 900 | 1080 |

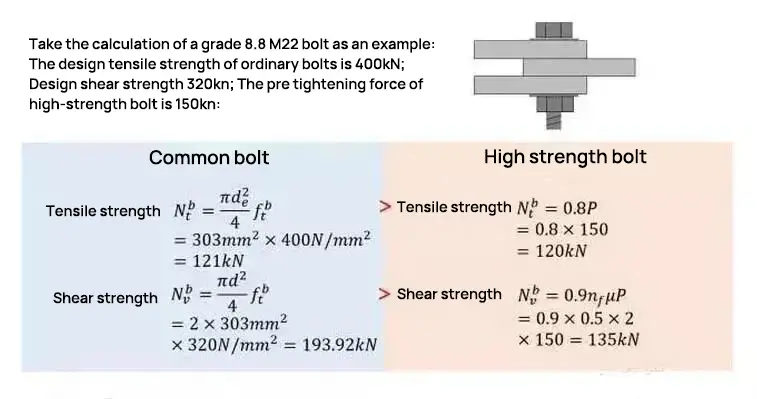

According to GB50017, calculate the tensile and shear strength of a single ordinary class B bolt of grade 8.8 and a high-strength bolt of grade 8.8.

To answer the question of where the “strength” of high-strength bolts lies, it is important to first understand the design working conditions and the laws of elastic-plastic deformation for both ordinary and high-strength bolts.

By studying the limit state of design failure, we can see that while the design values of tensile and shear strength may be higher for ordinary bolts under the same grade, the true strength of high-strength bolts lies in their ability to withstand more extreme loads without failing.

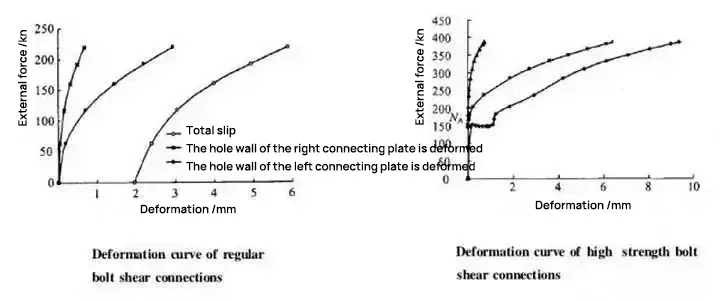

Stress-strain curves of ordinary bolts and high-strength bolts under working conditions

Limit state at design failure

For an ordinary bolt connection, the bolt itself undergoes plastic deformation that exceeds the design limit, resulting in shearing of the bolt. During this process, relative slip occurs between the connecting plates before the bolt begins to bear shear. This results in elastic-plastic deformation and bearing of the shear force.

In contrast, for a high-strength bolt connection, the static friction between the effective friction surfaces is the initial factor that bears the shear force.

As the load increases, the friction force may become insufficient to resist the shear force, and the static friction force is overcome. This results in relative displacement of the two steel plates, which is considered a failure in design considerations.

However, even when this occurs, the bolt rod can still use its own elastic-plastic deformation to bear the shear when it contacts the connecting plate.

Myth 2:

High bearing capacity is high strength bolt?

According to calculations for a single bolt, the tensile and shear design strength of high-strength bolts are lower than those of ordinary bolts. However, the true strength of high-strength bolts lies in their design joint properties.

When the joint is in normal working conditions, no relative slip is allowed, meaning that the elastic-plastic deformation is minimal and the joint stiffness is high. This results in a high safety reserve for the joint, even though the number of bolts may not be reduced compared to a design using ordinary bolts.

High-strength bolts are suitable for use in main beams and other positions that require high node stiffness, which aligns with the basic seismic design principle of having “strong nodes and weak members.”

Therefore, the strength of high-strength bolts is not found in the design value of their bearing capacity, but rather in the large stiffness, high safety performance, and strong damage resistance of their designed joints.

Due to their differing design stress principles, there are significant differences in the methods used for construction inspection of ordinary bolts and high-strength bolts.

Inspection requirements for ordinary bolts and high strength bolts

| Bolt | Common 8.8 | High strength 8.8 | ||||||

| Standard | BS3692 | ISO898 | Experimental value of a batch | BS4395-1 | ISO891 | Experimental value of a batch | ||

| Stretching | Yield strength | MPa | 640 | 885 | 635 | 817 | ||

| Tensile strength | MPa | 830 | 959 | 827 | 944 | |||

| Extensibility | % | 12 | 29 | 12 | 24 | |||

| Percentage reduction of area | 52 | 53 | 52 | 58 | ||||

| AKV | J | – | – | 30J | 33J | |||

| Chemical analysis | R | R | R | R | ||||

| Hardness test | HRC | 23-34 | 29.8 | 25-34 | 28.9 | |||

| HV10 | 256-335 | 294 | 260-330 | – | ||||

| Loading force | kN | 212 | – | 207 | – | |||

The mechanical performance requirements for ordinary bolts of the same grade are slightly higher than those for high-strength bolts.

However, high-strength bolts have a higher requirement for accepting impact energy compared to ordinary bolts.

The marking of ordinary bolts and high-strength bolts is a basic method for identifying bolts of the same grade on-site. It is also necessary to distinguish between high-strength bolts according to British and American standards, as their calculation of torque values may differ.

In terms of cost, ordinary bolts are approximately 70% less expensive than high-strength bolts. Given the comparison of their acceptance requirements, it can be concluded that the premium cost for high-strength bolts is to ensure their impact energy (toughness) performance.

Regardless of the complex loads they bear, the most common form of failure for high-strength bolts is fatigue failure.

As early as 1980, experts studied 200 cases of bolt connection failure and found that over 50% were due to fatigue failure.

Therefore, it is crucial to improve the fatigue resistance of high-strength bolts.

The fatigue fracture of bolts has the following characteristics:

For bolts, the main failure forms are plastic deformation of the threaded part and fatigue fracture of the screw. Out of these, the majority of damage occurs as follows:

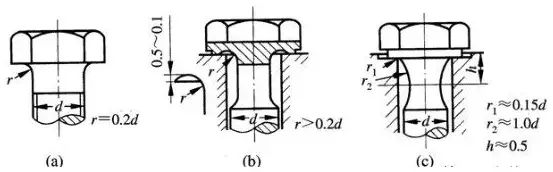

Strictly control the ending size of bolts to eliminate stress concentration:

a. Use large transition fillets

b. Cutting unloading groove

c. Cutting undercut at the end of thread

d. Optimizing the inclination angle of bolt head can also effectively reduce stress concentration

e. Use reinforced thread

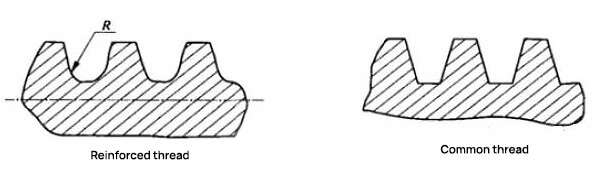

The primary differences between a reinforced thread and an ordinary thread are the minor diameter (d1) of the external thread and the root transition fillet radius (R).

The key features of a reinforced thread include a larger minor diameter (d1) compared to an ordinary thread, an increased root transition fillet radius (R), and a reduction in stress concentration in the bolt.

There are specific requirements for the root transition fillet radius (R) in a reinforced thread, with R+ = 0.18042P and rmin = 0.15011P, where P is the pitch. In contrast, there are no such requirements for an ordinary thread, which can even have a straight section.

Improving the control of the heat treatment and surface treatment processes during the manufacture of bolts can effectively enhance the bolts’ resistance to fatigue.

a. Heat treatment

Bolts undergo heat treatment followed by rolling to produce significant residual compressive stress, which slows the formation and growth of cracks and enhances their fatigue strength. It is important to prevent decarburization during heat treatment and to compare the fatigue strength of bolts with and without surface decarburization.

The presence of decarburization leads to oxidation of carbon in the layer, resulting in a reduction of cementite in the metallographic structure and lower strength and hardness compared to normal structures. Typically, the fatigue strength of bolts decreases by 19.8% under conditions of surface decarburization.

b. Phosphating

The phosphating treatment of bolt surfaces serves to prevent rust and ensure stable friction during assembly. Additionally, it can also decrease wear.

In the thread rolling process, reducing the friction between the thread rolling wheel and the screw thread can positively impact the stress distribution on the bolt thread after rolling and reduce the roughness of the thread surface.

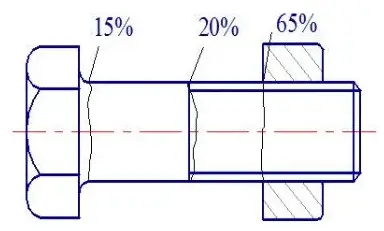

The tension in an ordinary bolt connection is mainly carried by the first three stressed threads. When the initial preload is substantial, plastic deformation occurs locally at the roots of some threads, leading to residual stress at those roots. This residual compressive stress enhances the fatigue strength of the threads.

Moreover, plastic deformation of the threads improves the stress distribution and reduces contact pressure, also enhancing the fatigue strength of the threads. The larger the preload, the better the bolt connection can resist separation and relaxation of preload. This results in a higher effective fatigue strength of the bolted connection.

Therefore, increasing the pre-tightening force in a bolt connection improves its ability to withstand fatigue failure under cyclic external loads and reduces the risk of fatigue failure from vibration and impact forces or limited overload.