What do the colors of titanium weld seams reveal about their quality? This fascinating question delves into the intricacies of welding titanium, a metal known for its reactivity and unique properties. The article explores how different seam colors, ranging from silver to gray, indicate varying levels of oxidation and weld quality. Readers will gain insights into the relationship between weld appearance and structural integrity, learning practical tips for achieving optimal welding results. Dive in to understand the science behind titanium welding and ensure your projects meet the highest standards.

Titanium is a highly reactive metal with unique chemical properties. It exhibits a strong affinity for oxygen, hydrogen, nitrogen, and other gases, especially at high temperatures.

This property is particularly pronounced during the welding process of titanium, where the strength of this ability increases with temperature.

Experience has shown that if the absorption and dissolution of gases like oxygen, hydrogen, nitrogen, and others are not controlled during welding, it can pose significant challenges to the welding process of titanium joints.

Related reading: 78 Welding Basics

Titanium welding is a frequently used welding method. The welding quality control in the process of titanium welding has a significant impact on the resulting weld color.

Due to the visual nature of titanium weld color, studying the correlation between the color of titanium welding seam and the welding quality is highly significant.

In this article, we aim to explore the relationship between the welding quality of titanium welding and the color of titanium welding seam based on our extensive research on titanium welding quality control and technology, as well as practical experience in the field. We hope that this article can contribute to further research in this area.

The interstitial melting of solid oxygen and nitrogen within titanium can distort its lattice structure, resulting in increased deformation resistance, strength, and hardness while decreasing its plasticity and toughness.

It is recommended to avoid the presence of oxygen and nitrogen during welding as it can have unfavorable effects.

The addition of hydrogen to titanium weld metal will significantly decrease its impact toughness, while also slightly reducing its plasticity. Furthermore, the presence of hydride can lead to brittleness in the joint.

At room temperature, carbon dissolves in titanium in the form of gaps, which increases strength and decreases plasticity, but its effect is not as pronounced as that of oxygen and nitrogen.

If the carbon content exceeds its solubility, hard and brittle TiC forms and is distributed in a network, which makes it prone to cracking.

The national standard specifies that the carbon content in titanium alloy must not exceed 0.1%.

During welding, oil contamination on the workpiece and welding wire can increase the carbon content. Therefore, it is essential to clean the surfaces before welding.

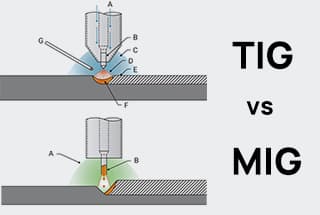

Titanium is known for its excellent weldability. Its low thermal conductivity (0.041 Cal/℃ · cm · s) allows it to only melt within the arc burning range and exhibit good fluidity.

Moreover, with a small coefficient of thermal expansion (8.6 × 10-6/℃, much lower than that of carbon steel), titanium metal’s weldability is greatly enhanced.

1. Color Change and Defect Generation Mechanisms in Welded Titanium and Titanium Alloy Pipes.

The weld defects of titanium and titanium alloy titanium pipes and their generation mechanisms are as follows.

Related reading: Types of Welding Defects

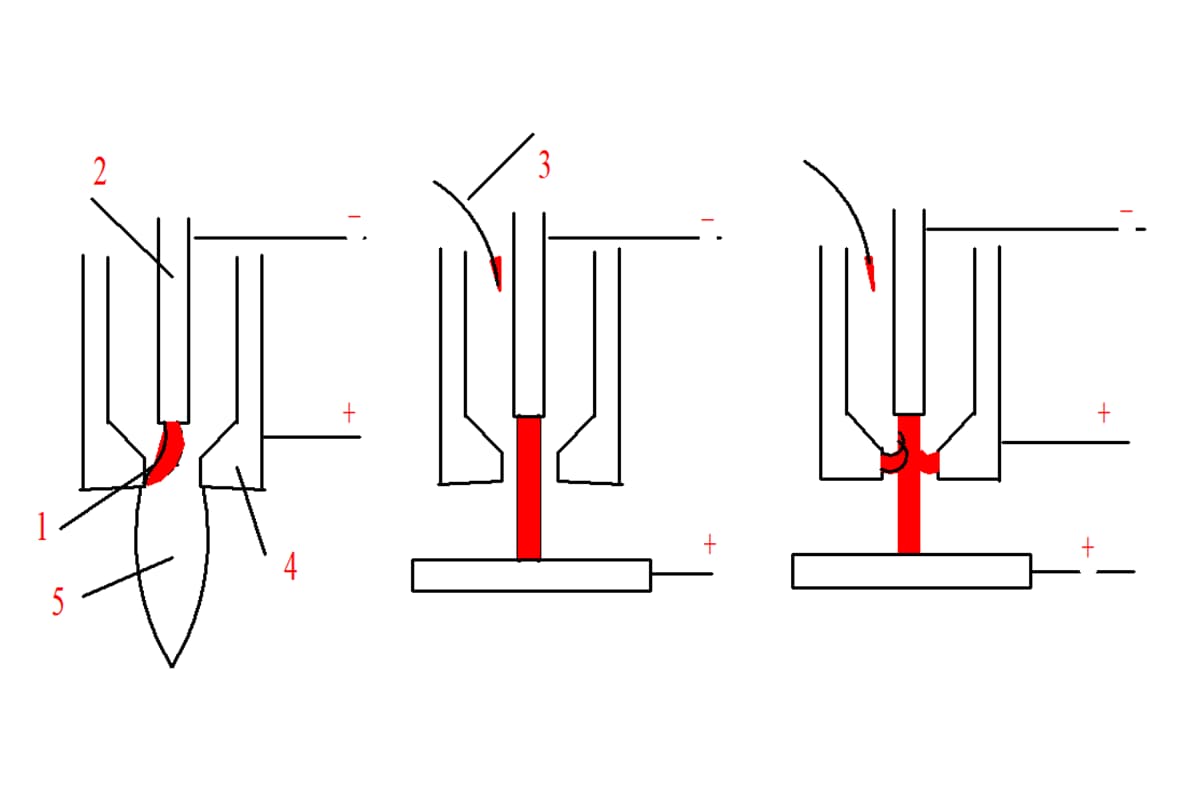

During the welding of titanium pipes, the argon arc welding gun creates an argon gas maintenance layer that only protects the welding pool from the harmful effects of air. However, this layer does not offer any protection to the solidified weld or the surrounding areas that are near the high-temperature state.

However, the weld on the titanium pipe and its surrounding areas in this state still have a strong ability to absorb nitrogen and oxygen from the air. This absorption process begins at 400 ℃ for oxygen and 600 ℃ for nitrogen, given that air primarily consists of nitrogen and oxygen.

With the increasing of oxidation level, the weld color of titanium tube changes and the weld plasticity decreases.

2. The quality of titanium welding can be judged by the color of titanium weld surface

The figure below displays tests for different colors and hardness of titanium welds.

(1) Experiments have shown that the hardness of the weld increases as the weld color deepens, indicating an increase in the degree of oxidation of the weld. In the case of the same trade, the hardness of titanium metal also increases, but harmful substances such as oxygen and nitrogen in the weld tend to increase as well, leading to a significant reduction in welding quality.

(2) The weldability of titanium is closely related to its chemical and physical properties, with the key factor being its vulnerability to air pollution at high temperatures due to its high activity. The grains of titanium swell when heated, and upon cooling, the welded joint can form a brittle phase.

Titanium has a very high melting point of 1668 ± 10 ℃, which requires more energy than welding steel. Additionally, titanium is more chemically active and more easily interacts with oxygen and hydrogen than steel, which results in rapid combination at temperatures above 600 ℃.

At a temperature of 100 ℃, a large amount of hydrogen (H) and oxygen (O) is absorbed, and titanium has the ability to dissolve H at a rate tens of thousands of times greater than that of steel. This generates titanium hydride, which significantly reduces toughness.

Gas impurities increase the tendency for cold cracking and delayed cracking, as well as notch sensitivity. Therefore, the purity of argon used for welding should not be lower than 99.99%, the humidity should not exceed 0.039%, and the hydrogen content of the welding wire should be below 0.002%.

The heat transfer coefficient of titanium is half that of steel. The transformation from α to β occurs at 882 ℃. The higher the temperature, the faster the β grain will grow, leading to a significant deterioration in performance. Therefore, temperature should be strictly controlled, especially the high-temperature residence time in the welding thermal cycle.

When welding titanium, there are no hot cracks or intergranular cracks, but there may be porosity problems, especially when welding α+β alloys.

Based on the above research, the following issues should be paid attention to when welding titanium metal:

1)During titanium welding, it is essential to strictly protect the welding area and the high-temperature area after welding to prevent air from entering and seriously affecting the weld quality. Therefore, it is necessary to use 99.99% pure argon and a trailing protective cover.

2)The weld groove must be machined, and grinding methods are not permitted.

3)Spot welding should be avoided, and high-frequency arc starting should be used instead.

4)It is recommended to avoid post-weld heat treatment. However, if it is necessary, the heat treatment temperature should not exceed 650 ℃.

The quality control of titanium welding has a significant impact on the color of the resulting weld. Additionally, the weld color of titanium welding can also serve as an indicator of the overall quality of the welding.

Therefore, there exists a crucial relationship between the two.