In the rapidly evolving world of manufacturing, CNC machines have become indispensable. But with numerous manufacturers vying for attention, how do you choose the best? As an experienced mechanical engineer, I’ve closely studied the top CNC machine manufacturers globally. In this article, I’ll share insights into the leading companies shaping the industry, helping you make informed decisions for your manufacturing needs. Get ready to discover the innovators driving the future of CNC machining!

Yamazaki Mazak, established in Japan in 1919, has evolved into a global leader in the machine tool industry, renowned for its innovative solutions in multi-tasking machining, five-axis processing, milling, turning, CNC systems, and automation. This pioneering company was among the first in its field to expand internationally, setting up manufacturing bases in the United States in 1974, and later in the UK, Singapore, and China, marking its commitment to a global production network.

Throughout its history, Mazak has been dedicated to driving globalization by not only expanding its manufacturing footprint but also by providing high-quality, technologically advanced products. This approach has enabled the company to make significant contributions to the manufacturing sector worldwide, aligning with its mission to enrich society and improve the quality of life through its manufacturing expertise.

Responding to contemporary challenges in the manufacturing sector, such as labor shortages, Mazak is leveraging cutting-edge technologies like the Internet of Things (IoT) and Artificial Intelligence (AI) to spearhead the development of new, innovative products and services. These efforts are focused on delivering solutions that enhance automation and foster smarter production facilities, thereby offering clients the tools needed to adapt to an ever-changing industrial landscape.

Yamazaki Mazak’s commitment to innovation, global expansion, and societal contribution forms the cornerstone of its identity as a leading machine tool manufacturer, shaping the future of manufacturing while upholding its rich legacy.

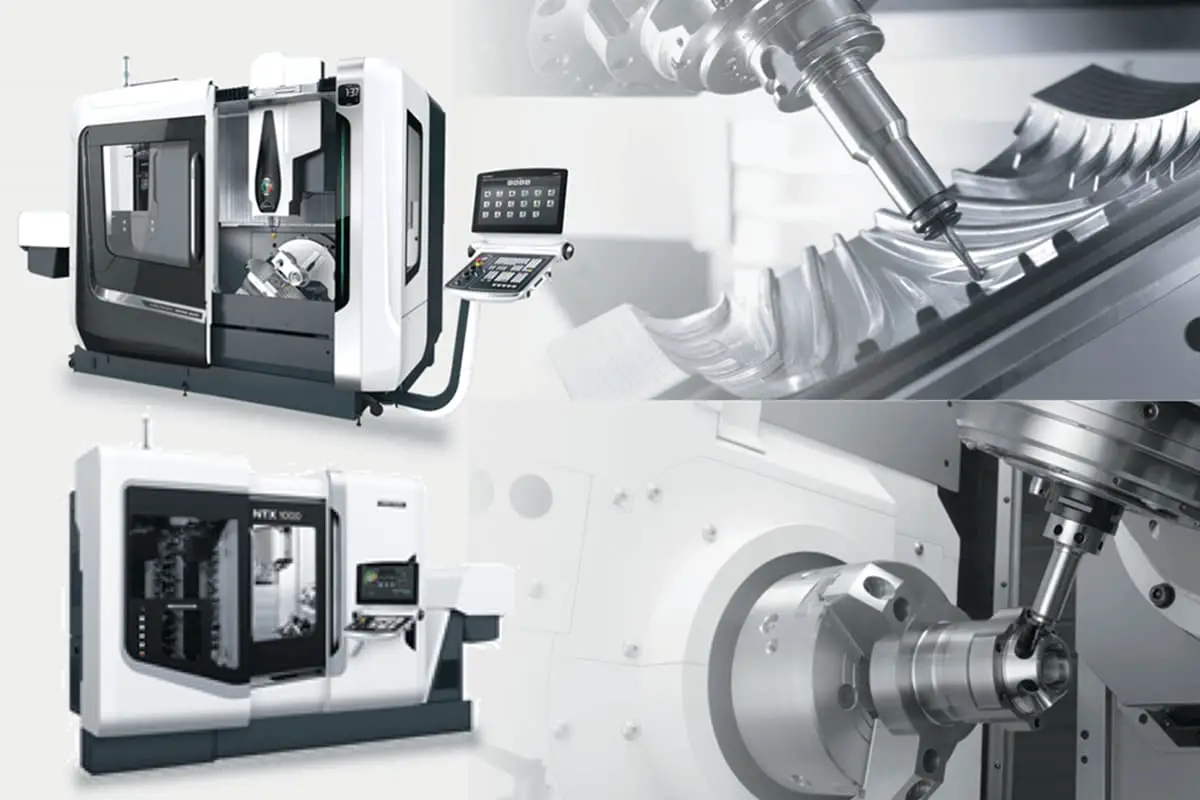

DMG MORI, a renowned brand in the CNC machine tool industry, was formed in 2013 through the merger of the Japanese tool machine giant Mori Seiki and the German company DMG. This merger brought together over 200 years of collective experience, blending Mori Seiki’s 65 years and DMG’s 143 years of expertise. DMG MORI represents the fusion of German and Japanese traditions in machine tool manufacturing, setting new technological standards and solutions in the field.

The company is recognized for its innovative and technology-driven solutions, continually developing trendsetting products. DMG MORI’s commitment to innovation has led to the optimization of both products and services, establishing new benchmarks in technology.

DMG MORI’s integrated approach to sales and services offers a comprehensive product line and a unique market presence. The company’s collaboration extends across sales and all technical service areas, including customer service, training courses, and technical support. With a global workforce of approximately 7,400 employees across 164 domestic and international sales and service centers in 76 countries, DMG MORI ensures extensive support for its clientele.

In an era where digitization is rapidly and radically transforming the world, DMG MORI is positively evolving in terms of technology, structure, and culture. The company’s ethos is marked by dynamism and excellence, embracing the shift to digitization as a fundamental part of its global and collaborative growth strategy.

Founded in 1923 in Germany, TRUMPF has evolved from a mechanical workshop to a global powerhouse in the industrial machine tools, laser technology, and electronic technology sectors. Celebrating a century of innovation, TRUMPF has established itself as a leader in the production of flatbed laser machines, accessories, and a range of other technologically advanced products.

TRUMPF’s journey into the 21st century saw the expansion into China with TRUMPF (China) Co., Ltd., enhancing its global footprint and market reach. This subsidiary specializes in manufacturing flatbed laser machines and accessories, with plans to expand into CNC punching machines and CNC bending machines.

With a rich history of over 80 years in machine tool production, TRUMPF stands at the forefront of technological innovation in laser technology, electronics, and medical equipment. The company’s commitment to digitalizing and optimizing production technology has not only made manufacturing processes more efficient and precise but also future-proof.

As of the fiscal year 2022/23, TRUMPF boasts an impressive workforce of 18,352 employees and generated sales revenues of 5,364.5 million euros, showcasing its significant impact on the industrial manufacturing sector. The company’s vision extends beyond current innovations, unlocking technological possibilities for future generations, making the unimaginable a reality in various sectors including industrial electronics and medical technology.

TRUMPF’s dedication to advancing the industrial world is evident in its diverse range of products and services, driving progress in almost every industry sector worldwide.

Founded in 1946 in Japan, Amada Co., Ltd. has grown into a globally recognized manufacturer of metalworking machinery. Specializing in sheet metal processing machines such as CNC turret punch presses, press brakes, shears, and laser cutting machines, Amada stands as a leader in the industry.

Amada’s evolution is marked by its expansive market size, diverse product range, advanced technological performance, and a comprehensive management system. This transformation has established Amada as a conglomerate with a robust presence in product development, design, manufacturing, education, training, and after-sales service, all underpinned by an extensive marketing network. As a publicly traded group company, Amada demonstrates a commitment to innovation and customer satisfaction.

With a global footprint, Amada operates 83 branches across continents, marketing its products in over 100 countries. The variety, performance, and cutting-edge technology of its sheet metal processing machinery have earned Amada a leading position in the global market. The company’s pioneering development of the 21st-century intelligent automated sheet metal processing center in the 1990s set a precedent for smart manufacturing in the sheet metal industry.

Amada’s success in the global market is attributed to its machines’ rational design, offering high-quality assurance, environmentally friendly operations, and benefits for users. Their advanced technology in automated processing ensures simplified operations, contributing to Amada’s worldwide reach. The company’s impressive annual sales of 200 billion yen testify to its market impact and customer trust.

Headquartered in Isehara-shi, Kanagawa, Japan, Amada Co., Ltd. is a comprehensive manufacturer of metalworking machinery, with a consolidated workforce of 8,958 employees as of March 31, 2023. The company’s extensive product line includes sheet metal machinery, cutting machines, grinding machines, stamping presses, and micro welding equipment, along with software, peripheral equipment, tooling, maintenance, and service. As a global entity, Amada’s vision extends beyond manufacturing to contributing to the development of the metalworking industry, always keeping the customer’s perspective at the forefront.

Okuma Corporation, a Japanese company established in January 1898 and incorporated in July 1918, stands as a leading manufacturer and supplier of integrated machine tools and control devices. With a rich history exceeding 120 years, Okuma is recognized for its high-quality CNC lathes, machining centers, grinders, CNC controls, FA products, and servo motors. Its headquarters in Oguchi-cho, Niwa-gun, Aichi Prefecture, Japan, is led by President Atsushi Ieki and employs 3,802 consolidated employees as of March 2021.

Okuma has made significant contributions to the machine tool industry, such as developing the OSP CNC control with an absolute position encoder, positioning itself as Japan’s only comprehensive manufacturer of both machine and control. Their commitment to innovation is further exemplified by the development of the “Thermo-Friendly Concept” and “Collision-Free Machines,” showcasing Okuma’s dedication to precision and reliability.

The company’s ethos revolves around delivering integrated machine tool solutions with superior quality and service to meet the evolving needs of customers worldwide. This commitment extends to sustainability efforts, as Okuma focuses on reducing environmental impact and promoting a sustainable society through its long-lasting, recyclable machine tools.

With a global presence, Okuma has major operations in the USA, Germany, Singapore, Taiwan, Thailand, Australia, China, Korea, India, and Indonesia, including subsidiaries like Okuma America Corporation, Okuma Europe GmbH, and others across the globe. Okuma’s historical milestones, such as the establishment of various international subsidiaries and the launch of groundbreaking technologies, reflect its position as a global leader in the machine tool industry.

Dalian Machine Tool Group Co., Ltd., operating under China General Technology Group since April 2019, is a leading enterprise in the Chinese machine tool industry with a heritage dating back to its establishment in 1935. Renowned for its CNC machine tools, flexible manufacturing systems, and automation technology and equipment, the company has firmly positioned itself as a vital base for the industrialization of functional components.

With modern production bases in Dalian’s Double D Port and Wafangdian covering over 1.1 million square meters, Dalian Machine Tool has a comprehensive range of nearly 2,500 sophisticated machines and holds more than 80 patents. Its product portfolio includes CNC flexible combination machine tools and automatic lines, intelligent manufacturing units and production lines, five-axis machining centers, turning and milling centers, high-speed precision machining centers, industrial robots, CNC systems, and key components like ball screws and linear guides.

Throughout its 80-plus years, Dalian Machine Tool has supplied over half a million machine tools across various industries, such as automotive, rail transit, engineering machinery, petroleum machinery, and mining metallurgy, extending its market to over 100 countries worldwide. The company has maintained a domestic leadership position in product innovation, with some products reaching international standards. It has been a driving force in national technological innovation, contributing significantly to China’s strategic emerging industries with over 247 new products developed from 2013 to 2016.

Under the guidance of China General Technology Group and with a strong focus on intelligent manufacturing and key components, Dalian Machine Tool continues to enhance its core competitiveness, aiming to become a globally competitive, world-class machine tool enterprise and contribute to the revitalization of China’s machine tool industry.

Shenyang Machine Tool Part Co., Ltd., established in 1993 through the merger of four leading companies, has risen to become a prominent figure in the machine tool industry. As a subsidiary of the larger Shenyang Machine Tool (Group) Co., Ltd., this company is renowned for its exceptional quality and comprehensive range of products, including horizontal lathes, gantry machining centers, horizontal milling and boring centers, and vertical machining centers. With a history dating back to 1933, it stands as one of China’s largest and most respected lathe manufacturing bases.

After going public in 1996 and being listed on the Shenzhen Stock Exchange with the stock code 000410, the company has consistently focused on innovation and quality. By embracing new technologies and materials, such as the successful substitution of the LZA4205 microcrystalline alloy for the traditional ZQSn6-6-3 brass in its CNC turret branch, Shenyang Machine Tool Part Co., Ltd. has not only improved the quality of its products but has also gained a competitive edge by effectively controlling costs.

The company’s commitment to excellence extends to its service offerings. It is a multifaceted service provider, adept in marketing and providing value-added services for SMTCL Shenyang machine tool products and CNC lathe machines. It offers a full spectrum of services including sales of complete spare parts, maintenance, overhaul, transformation, and processing of mechanical equipment, as well as consulting, technical training, and import-export trade. This is all part of their dedication to making the selection of machine tool spare parts easier and more efficient for their clientele.

In recent years, the Shenyang CNC Machine Tool Industrial Park has been relocated and restructured for specialization, housing nine enterprises that span the entire gamut of machine tool production. This strategic move has positioned the Industrial Park to become one of the largest and most modernized CNC machine tool manufacturing bases in the world.

Overall, Shenyang Machine Tool Part Co., Ltd. stands as a testament to China’s industrial prowess, with a steadfast approach to innovation, customer service, and global competitiveness. It continues to forge partnerships within the industry, aiming to serve customers better and enhance value in an ever-evolving market.

Founded in 1937, Jinan Second Machine Tool Group Co., Ltd., is a preeminent manufacturer of stamping equipment, recognized as one of the largest forging equipment and heavy-duty metal cutting machine tool bases in China. With a sprawling facility spanning over 1.23 million square meters and a dedicated workforce of over 5,000 employees, the company has made significant contributions to China’s industrial landscape.

Jinan Second Machine Tool Group has a storied history of innovation, having developed China’s first gantry planer in 1953 and the first mechanical press in 1955, earning its reputation as the birthplace of the country’s gantry planing and mechanical press industries. Throughout different periods of economic development, the company has invented over 600 national pioneering products, providing vital equipment support to key industrial sectors.

The company’s extensive product range includes forging equipment, CNC metal cutting machine tools, automation equipment, foundry machinery, and CNC cutting devices. These products serve critical roles in industries such as automotive, aerospace, rail transportation, energy, shipbuilding, metallurgy, mold manufacturing, and construction machinery. Furthermore, their reach extends to 67 countries and regions worldwide, bolstering the company’s status as one of the top three CNC stamping equipment manufacturers globally.

Jinan Second Machine Tool Group’s commitment to excellence has not gone unnoticed, as it has been honored by the State Council for its significant contributions to the field of major technical equipment. This accolade underscores the company’s impact on industry advancements, both within China and across the global market.

The EMAG Group, with its inception in 1867 in Germany, stands as a pioneer and global leader in CNC inverted machine tool manufacturing. Renowned for its innovation and precision in developing series of CNC machine tools, EMAG primarily focuses on the automotive, machinery, aerospace industries, renewable energy, electricity, and oil sectors. Its offerings include machining tools for disc, shaft, and box-shaped parts, inverted lathes, and multifunctional production centers.

EMAG has expanded significantly in China since establishing its Shanghai office in 2003 and the Taicang subsidiary in 2004, now known as EMAG (China) Machinery Co., Ltd. Taicang Branch. This fully-owned subsidiary of the German parent company covers an area of 10,000 square meters, employs 170 people, and reported sales of two hundred million euros in 2017. The branch also has offices in Beijing and Guangzhou. EMAG (China) Machinery Co., Ltd. Taicang Branch specializes in customized services for high-performance inverted CNC turning centers and sells all products produced by the Group, including a wide range of machine tools catering to various industries like automotive, oil extraction, construction machinery, hydraulic components, and aerospace.

EMAG’s commitment to quality is evident in its innovative manufacturing philosophy, systematic training for its Chinese employees, and modern facilities equipped with advanced machinery. All EMAG machine tools and production systems are designed and developed in Germany. The company’s inverted machine tools and automated integrated systems significantly reduce loading and unloading times and the machining cycle, contributing to higher efficiency and reduced costs. For Chinese customers, the combination of high quality and efficiency is particularly compelling. Furthermore, the ergonomic design of its fully automated integrated systems makes operation more straightforward and intelligent, reducing the workload of employees and enhancing safety and comfort at work.

From the EMAG Group’s history page, it’s clear that the company’s journey has been marked by continuous innovation, expansion, and recognition for its contributions to the machinery industry. Key milestones include the integration of Samputensili Machine Tools and Samputensili CLC into EMAG SU Srl in 2021, acquisition of CNC-Technik Weiss GmbH in 2019, and various awards like the Axia Best Managed Companies Award in 2019. EMAG’s growth has been complemented by acquisitions and technological advancements, affirming its status as a pioneer in machine tool manufacturing.

Founded in 1930 by Tsunezo Makino in Tokyo, Japan, Makino Milling Machine Co., Ltd. is a global leader in the manufacturing of CNC metalworking machinery. Emphasizing quality-first in every product and service, Makino has evolved into a large enterprise providing flexible processing solutions in automotive, aerospace, and mold processing industries.

Operating from its global headquarters in Tokyo, Makino has expanded its reach to Japan, Mainland China, South Korea, and Taiwan, offering machinery, tools, and innovative solutions. The company’s R&D in Tokyo led to the commercialization of horizontal machining centers, marking a milestone in mechanical equipment and systems innovation.

As an industry frontrunner in mechanical design and digital innovation, Makino has introduced groundbreaking solutions with exceptional performance. The company’s product line boasts highly precise and quality metal cutting and EDM machinery, including horizontal, vertical, and five-axis machining centers, graphite processing centers, and wire and sinker EDM machines.

With a capital of 21,142 million yen as of March 2023 and a consolidated sales figure of 227,985 million yen, Makino employs 4,692 staff globally. The company’s expansive presence includes manufacturing plants in Atsugi (Kanagawa) and Fuji-Katsuyama (Yamanashi), and sales offices across 17 locations in Japan. Internationally, Makino operates in the United States, Germany, Singapore, Korea, China, India, and several other countries.

Makino’s commitment to sustainability and trust as the foundation of corporate existence is reflected in its diverse range of high-quality products and services. Today, Makino’s products are distributed in over 41 countries and regions worldwide, upholding its legacy of innovation and quality in the field of CNC machinery.