Have you ever wondered how the gears in your car or airplane work so smoothly? This article unveils the top gear manufacturers shaping the future of mechanical engineering. You’ll learn about the pioneers, their innovations, and the industries they revolutionize. Get ready to explore the fascinating world of gears and their creators.

Country: USA

Founded:1865

About the company:

Gleason, founded in 1865, is a global leader in gear technology. The company offers machine tools, gear finishing, and testing services, as well as global technical support that includes cutting tools, fixtures, parts replacement, on-site services, application development services, gear design and testing software, project training, engineering support, machine tool transformation, and upgrading services.

Its customers come from a wide range of industries, including the automotive, aerospace, energy, heavy vehicles, recreational vehicles, and electrical equipment industries.

William Gleason, the founder of Gleason, was born on April 4, 1836, in Boriskane, Tipperary County, Ireland. He immigrated to the United States with his mother and brother at the age of 15 and received training as a mechanic at machine processing plants in Rochester. During the Civil War, he worked at the Cote Armory in Hartford, Connecticut. In 1865, he returned to Rochester and opened his own machinery factory, which would later develop into the Gleason company we know today.

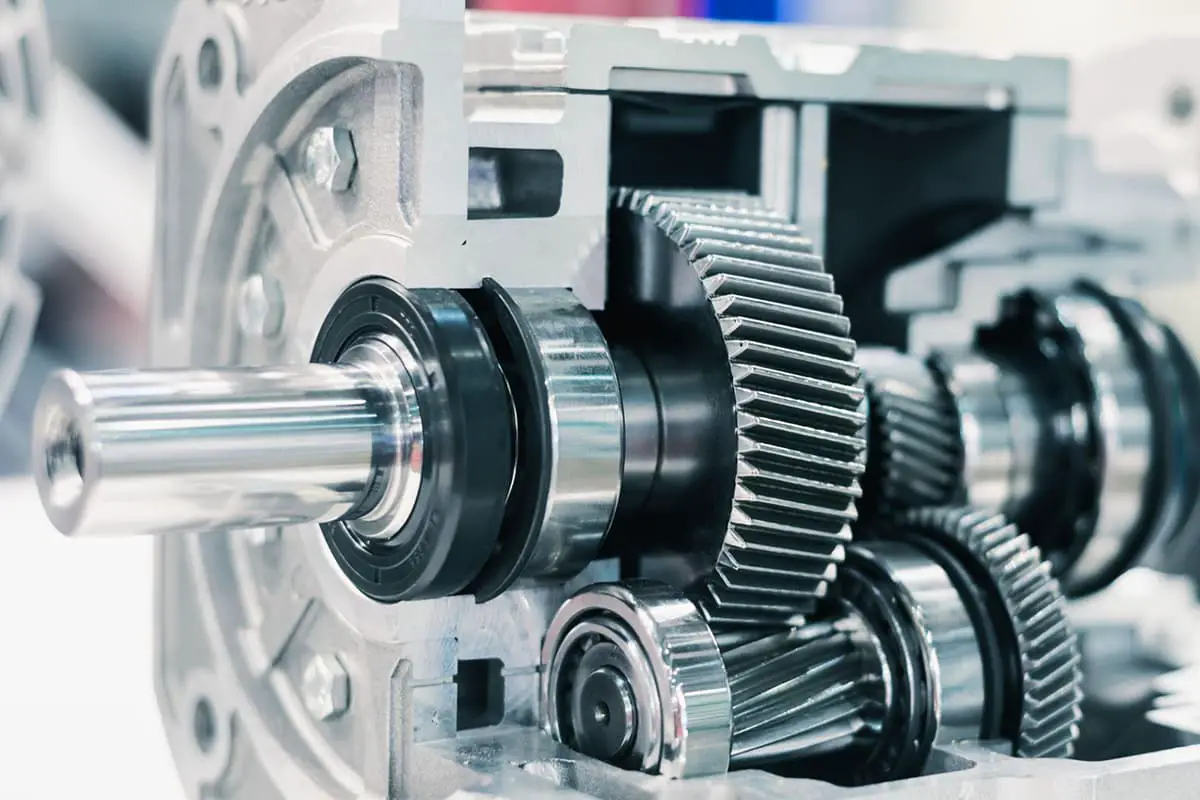

Initially, the factory produced a variety of metal processing tools and machine tools, such as lathes and planers. In 1874, William Gleason invented the first bevel gear shaping machine, marking the beginning of the bevel gear industry and opening up new possibilities for power transmission. Today, Gleason specializes in the design, manufacturing, and sales of bevel gear and cylindrical gear machine tools and cutters.

Bevel gears are used to change the transmission angle of force, such as from a driving shaft to the rear axle of a vehicle, while cylindrical gears are used for rotating force transmission. Gleason provides a full range of bevel gear machine tools and cutters, as well as cylindrical gear machine tools and cutters.

Country: Germany

Founded: 1863

About the company:

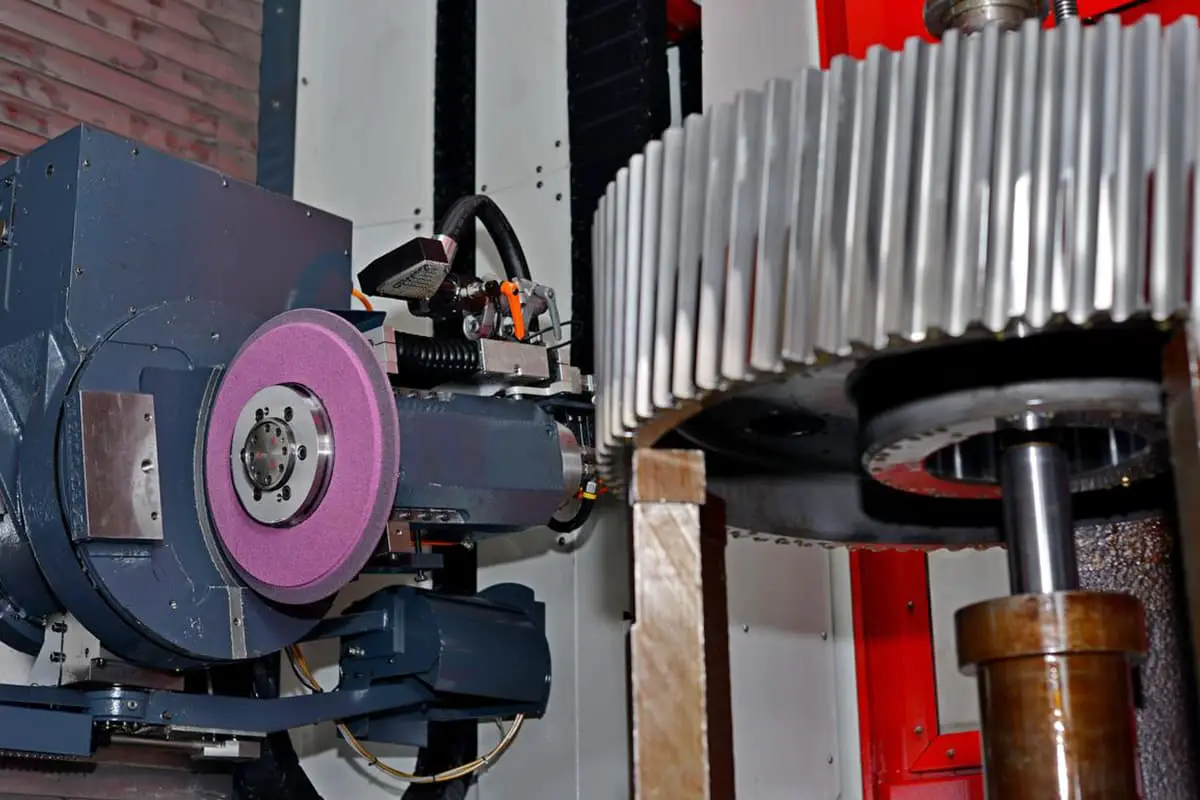

Klingelnberg was founded in 1863 as a traditional machinery company. At its inception, the company’s main focus was the production of various mechanical cutters in its factory located in Remshaid, Germany. In 1923, the company launched its first bevel gear hobbing machine tool equipped with an adjustable taper angle milling head, causing a shift in the market.

Klingelnberg Group is a leader in the industry thanks to its more than 200 patented technologies, which have set international standards in its core areas, including the development and manufacture of bevel gear and cylindrical gear machining machines, precision measuring centers for gears and axisymmetric workpieces, and the production of high-precision driving components.

For over 150 years, Klingelnberg has been at the forefront of the small and large wheel and transmission industries. With the rise of Industry 4.0, the company has pushed the gear production standard to a new era. Their products are critical for the development of a wide range of industries, including ocean-going oil tankers, lignite mining, grain processing, wire rod mills, aviation, heavy construction machinery, and the automotive industry.

Klingelnberg specializes in the production of important transmission parts, such as cylindrical gears, bevel gears, worm gears, and rotors, with diameters ranging from a few millimeters to several meters. The company’s long-standing focus on these components has allowed it to become one of the leading enterprises in the world gear processing industry.

Country: Japan

Founded: 1935

About the company:

KHK Co., Ltd., also known as Xiaoyuan Gear Industry Co., Ltd., is a renowned Japanese standard gear manufacturer. The company has a broad range of standard gear production lines and uses its highly professional technology and manufacturing experience to provide customers with customized gears to meet their diverse needs.

Over the years, KHK has continuously improved its products and received high praise from customers for its wide variety of standard gear types and diverse custom gears. With its extensive technology and experience, the company can provide almost all types of gears, including spur gears, helical gears, bevel gears, worm gears, and racks.

By using KHK’s standard gear, customers can save time in designing gear from scratch.

KHK Co., Ltd. offers a wide range of gears, including spur gears, rack gears, bevel gears, worm gears, and others, allowing customers to select the ideal gear based on the number of teeth, materials, modulus, accuracy (grinding availability), and hardness (quenching availability). Using the KHK standard gear sample, customers can quickly find the gear they need.

All standard gears, except for the J series, are available in the company’s warehouse, and a dedicated team member will be responsible for delivering the standard gears to meet the customer’s short delivery time requirements. The company also implements a unique inventory management system to ensure the optimal inventory level of standard gears and ensure normal supply.

Country: China

Founded: 1980

About the company:

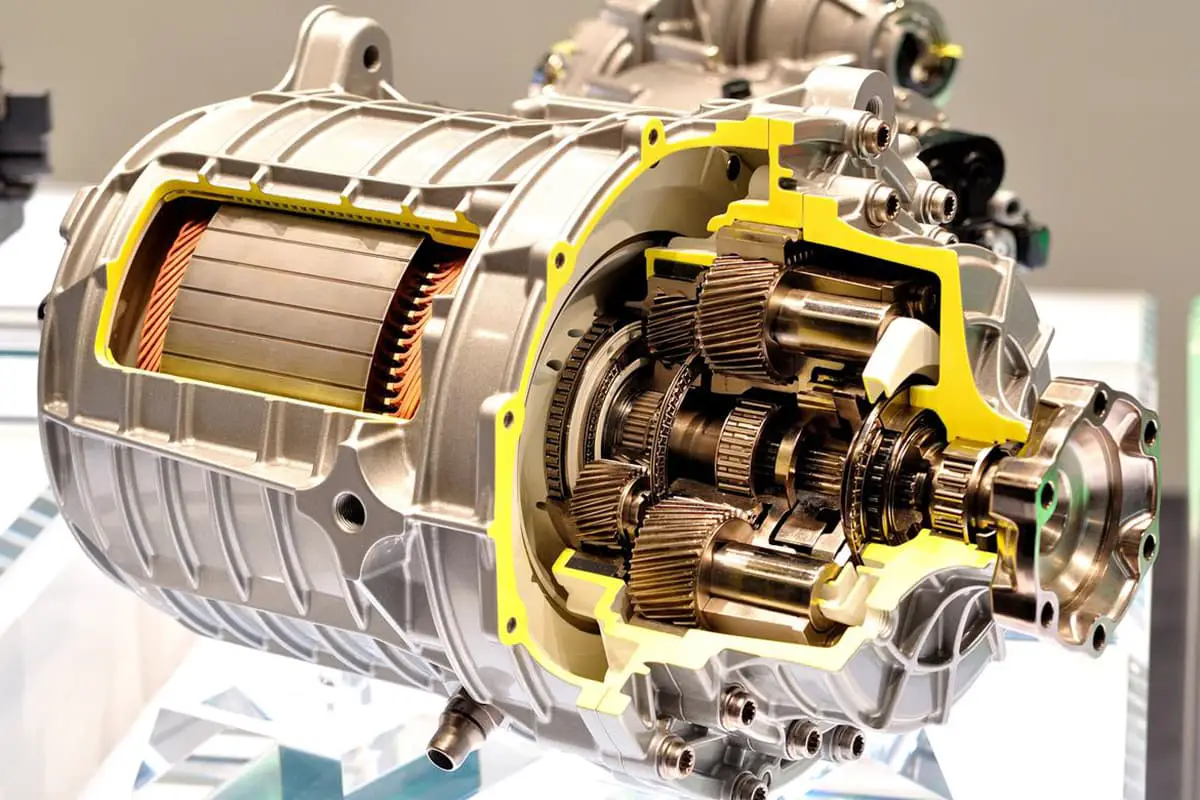

Zhejiang Shuanghuan Transmission Machinery Co., Ltd. (Stock code: 002472), established over 40 years ago, has focused on the research, development, manufacturing, and sales of core components of mechanical transmission gears and components. The company has become one of the world’s largest professional gear product manufacturers and service providers.

Its products are used in a variety of fields, including traditional automobiles, new energy vehicles, rail transit, non-road machinery, industrial robots, and more. The company has a global presence, serving as a supplier for well-known enterprises such as ZF, Cummins, Caterpillar, SAIC, FAW, and others. Over 60% of its customers are part of the Fortune 500.

Zhejiang Shuanghuan Transmission Machinery Co., Ltd. has become a global strategic supplier of Caianghu high-speed railway gears due to its high-performance high-speed railway gears.

The company has also completed innovative research and development of industrial robot joints (RV reducers) and is transitioning to industrialization. In the new energy automotive industry, its gears cover half of the Chinese market.

Country: China

Founded: 1992

About the company:

Jiangsu Pacific Precision Forging Technology Co., Ltd. is a leading supplier of precision forging gears in the industry, with a registered capital of 481.77 million yuan. The company is focused on the research, development, and sales of automobile precision forging gears and other precision forgings.

As a high-tech enterprise with independent innovation capabilities, advanced core technology for gear mold design and manufacturing, and cold, warm, and hot precision forging forming technology, Jiangsu Pacific Precision Forging Technology Co., Ltd. specializes in manufacturing automotive gears.

The company has established an enterprise technology center and postdoctoral research workstation, and currently holds 115 authorized patents, including 4 PCT international invention patents, 30 national invention patents, and 81 utility model patents.

The main products of the company are automotive differential half-shaft gears, planetary gears, and transmission combination gears. These products have been highly recognized by domestic and foreign mainstream vehicle manufacturers and their powertrain suppliers, and have been integrated into the global procurement systems of companies such as GKN, MAGNA, W, GM, GETRAG, AAM, DANA, and John Deere. The products are also used in many models of Volkswagen, General Motors, Ford, Toyota, BMW, and Mercedes Benz.

Jiangsu Pacific Precision Forging Technology Co., Ltd. is the leading enterprise in the precision forging gear industry for passenger cars in China, and its production and sales of precision forging gears for cars are among the best in the industry. The company has a long history of researching, developing, and applying advanced forging technology, and has a full business process with a wealth of experience.

On August 26, 2011, the company was successfully listed on the GEM of Shenzhen Stock Exchange and became a publicly traded company under the stock name “Precision Forging Technology” with the stock code 300258.

Country: China

Founded: 2001

About the company:

Seashine, established over a decade ago, has become a prominent manufacturer of PM parts for electric tools in China. It boasts its own strengths in product research and development, production organization, customer relationships, and offers over 1,500 structural products for electric tools.

With years of innovation, the company has introduced new products in the fields of electric tools, office equipment, and automobiles. It has established long-term partnerships with many international power tool and electrical manufacturing companies, and has become a supplier for numerous domestic automotive companies.

Seashine exports the majority of its products to countries such as the United States, Germany, India, Japan, and others. The company is actively expanding its market for medium and high-end automotive powder metallurgy products and aims to replace imported and foreign monopoly products with domestic alternatives.

The company is well-equipped with 34 patented technologies and has been recognized for its high-tech products and enterprises in Jiangsu Province, as well as obtaining ISO/TS16949 certification. Seashine is dedicated to becoming a leading enterprise in the powder metallurgy industry both domestically and globally.

Country: China

Founded: 2005

About the company:

Zhejiang Zhongma Transmission Co., Ltd., formerly known as Zhejiang Zhongma Automobile Transmission Co., Ltd. is a subsidiary of the Zhongma Group. The company was established in December 2005 and listed on the Shanghai Stock Exchange in June 2017.

The manufacturing base is located in Shangma Industrial Park, Wenling City and covers an area of 230,000 square meters, with 180,000 square meters completed.

The plant includes technical centers, testing and detection centers, transmission and new energy vehicle reducer assembly workshops, single machine automation, split frame automation production lines, intelligent processing units, energy conservation and environmental protection systems, staff living quarters, etc.

As a national high-tech enterprise, the company is focused on R&D, design, manufacturing and sales of automobile transmissions, new energy vehicle reducers, and transmission gears.

With over 70 patents, it has been certified for quality management system (ISO/TS16949), environmental system (ISO14001) and occupational health and safety management system (ISO45001). The company follows a performance management mode and has a strong quality assurance system.

Zhejiang Zhongma Transmission is committed to the future and focuses on technical talent and management team development. It has established a postdoctoral workstation, a provincial technology center, and a research institute.

The company is dedicated to industry-university research cooperation and has set up a research and development base to develop new energy vehicle hybrid power transmissions, light rail parts and transmissions, agricultural machinery parts and transmissions, a new generation of high-performance manual transmissions, and high-speed pure electric vehicle transmissions. The company’s goal is to “drive the world and serve the world.”

Country: China

Founded: 1996

Products: auto manual transmission assembly, white transmission assembly, new energy reducer, textile machinery transmission assembly and auto transmission gear, shaft, synchronizer and other parts, auto engine gear and shaft and other parts, key components of textile machinery, auto engine cylinder block Transmission housing, automobile steering gear housing, mechanical die-casting parts

About the company:

Landai Technology Group Co., Ltd. was established in 1996 as Chongqing Landai Industry Co., Ltd. The company’s shares were listed on the Shenzhen Stock Exchange in 2015 with the stock code of 002765 and stock abbreviation of Landai Technology.

In 2019, the company completed the acquisition of 89.6765% equity of Taiguan Technology and now holds 99.6765% equity of the subsidiary. The company has transformed from the power transmission business to a combined model of power transmission and touch screen and touch display module business.

The company’s main business in power transmission is the research, development, design, manufacturing, and sales of power transmission assembly, transmission parts, and die-casting products.

The products are mainly used in the automotive industry, textile machinery, and general machinery fields and have established a strong market position in the power transmission field. The company has a number of well-known power transmission component customers both domestically and internationally. Some of its products are exported to the Middle East.

The touch screen and touch display module business is mainly involved in the research, development, production, and sales of touch screen and touch display-related products, including capacitive touch screens, touch display modules, cover glass, touch sensors, and other components.

These products are used in various information terminals such as tablet computers, laptops, industrial control terminals, automotive electronics, and Internet of Things devices.

Taiguan Technology focuses on developing customers from advanced manufacturers globally and has become a supplier to well-known enterprises such as Quanta Computer, Renbao Industry, BOE, Huaqin Communication, and GIS. Its products are finally applied to international well-known brand electronic products such as Amazon and Acer notebooks.

Country: China

Founded: 1999

About the company:

Zhejiang Feng’an Gear Co., Ltd. was founded in 1999 as a professional gear manufacturer that provides development, design, manufacturing and sales services. The company is located in Zhejiang, covers an area of 93 mu, and has a total asset of over 300 million yuan with more than 400 major equipment. In January 2017, the company was listed on the “New Third Board” with stock code 870508.

Over the years, the company has transformed its business mechanism and adjusted its product structure, forming a complete product development, production and management system.

The company is equipped with advanced gear processing, heat treatment, and other technological equipment and has a complete detection system. It specializes in processing and producing gears for tractors, harvesters, engineering machinery, forklifts, and other series with 5-9 accuracy and 12 modules, with an annual production capacity of 5 million pieces.

Feng’an has strong technical force, a perfect quality system, and advanced production technology. Its products are well-sold in many countries and regions around the world and have a good reputation in the market.

With the business philosophy of “survival-based, development-focused, steady operation, and sustainability-pursuing,” the company has focused on technology research and development and market exploration, constantly increased its innovation, and actively promoted its technological progress. It has established a technology center and postdoctoral workstation to further its progress.

Country: China

Founded: 1995

company offers a range of products including:

About the company:

Founded in 1995, Zhejiang FORE is a leading provider of intelligent drive research and development and system integration services. The company has a strong focus on small module gears and has diversified its product offerings over the years. With a focus on sustainable growth, the company has expanded its operations to upstream and downstream industries, with the goal of becoming an industry leader.

Zhejiang FORE places a strong emphasis on its people, and has developed a talent management system to attract, retain, and develop its employees. The company values teamwork, dedication, and innovation, and has a strong corporate culture focused on honesty, diligence, harmony, and responsibility.

The company uses information technology and lean management principles to effectively combine people and technology. The company has adopted a range of information management technologies, including ERP, OA office automation, MES, PLM, and CAE aided design.

Zhejiang FORE has also been certified with ISO9001, TS16949, and ISO14001 management systems and has implemented the BPS project of German BOSCH, with a focus on lean production processes to achieve more efficient cycles and cost savings.

When choosing a gear manufacturer, there are several factors that I consider to ensure I get high-quality gears that meet my needs. Below are some of the factors I consider:

Reliability is one of the most important factors I consider when choosing a gear manufacturer. I want to be sure that the gears I get will function as expected and not fail prematurely. To ensure reliability, I look for manufacturers who have a proven track record of producing high-quality gears that last long.

Quality is another important factor that I consider when choosing a gear manufacturer. I want to be sure that the gears I get are made from high-quality materials and meet the required industry standards. To ensure quality, I look for manufacturers who have a reputation for producing high-quality gears and have certifications from recognized quality assurance bodies.

Price is also an important factor that I consider when choosing a gear manufacturer. I want to get high-quality gears at a reasonable price. To ensure I get the best price, I compare the prices of different manufacturers and choose the one that offers the best value for money.

Customer service is another factor that I consider when choosing a gear manufacturer. I want to be sure that I can get the support I need in case of any issues with the gears. To ensure good customer service, I look for manufacturers who have a responsive customer service team that can provide timely assistance whenever I need it.

In conclusion, when choosing a gear manufacturer, I consider the reliability, quality, price, and customer service of the manufacturer. By considering these factors, I can ensure that I get high-quality gears that meet my needs and offer good value for money.