Cracks during gear grinding can be a costly problem, but understanding their causes and solutions can save both time and money. This article explores why these cracks occur, such as excessive heat and improper heat treatment, and offers practical prevention measures like optimizing grinding techniques and controlling material properties. By implementing these strategies, you can enhance the durability and performance of gears. Dive in to learn how to maintain the integrity of your gear manufacturing process and avoid common pitfalls.

In modern hard tooth surface gear grinding, the grinding area only grinds the part of the involute tooth profile that is above the starting circle and below the terminating circle of the involute.

Modern hardened gear surfaces have the following benefits when the gear root is not ground in the gear grinding process:

(1) It avoids the reduction of gear root hardness after heat treatment, maintaining a negative stress layer formed on the gear surface and root after carburizing, quenching, and shot peening. This significantly improves the gear’s resistance to bending fatigue and load-bearing capacity.

(2) The narrow bottom of the gear root groove, poor heat dissipation, and significant variation in the remaining material at the excessive curve drastically affect the grinding wheel’s working conditions. This can easily cause grinding burns and cracks during gear grinding.

(3) Poor grinding conditions at the bottom of the gear root groove make the grinding grains on the outer circle of the grinding wheel prone to falling off and wearing out, thereby affecting the quality of gear grinding.

(4) In terms of tooth-breaking resistance, the gear root must have a certain amount of root cutting. Without a certain amount of root cutting, inevitable protrusions will occur at the gear root during gear grinding. This will lead to serious stress concentration, greatly affecting tooth-breaking resistance. The occurrence of such protrusions is absolutely unacceptable.

In conclusion, not grinding the root of the gear groove can improve the gear’s load-bearing capacity, prevent damage during gear grinding, improve the quality of gear grinding, reduce the load on the grinding process, and enhance productivity.

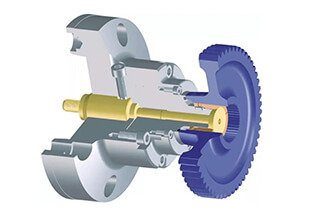

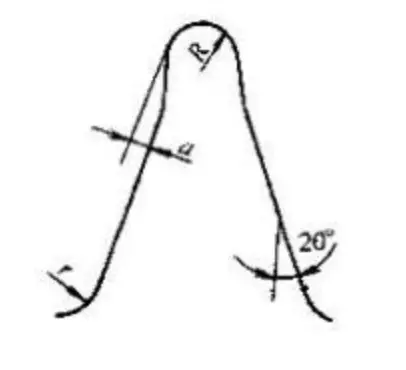

(1) Introduction to pre-grinding hobs

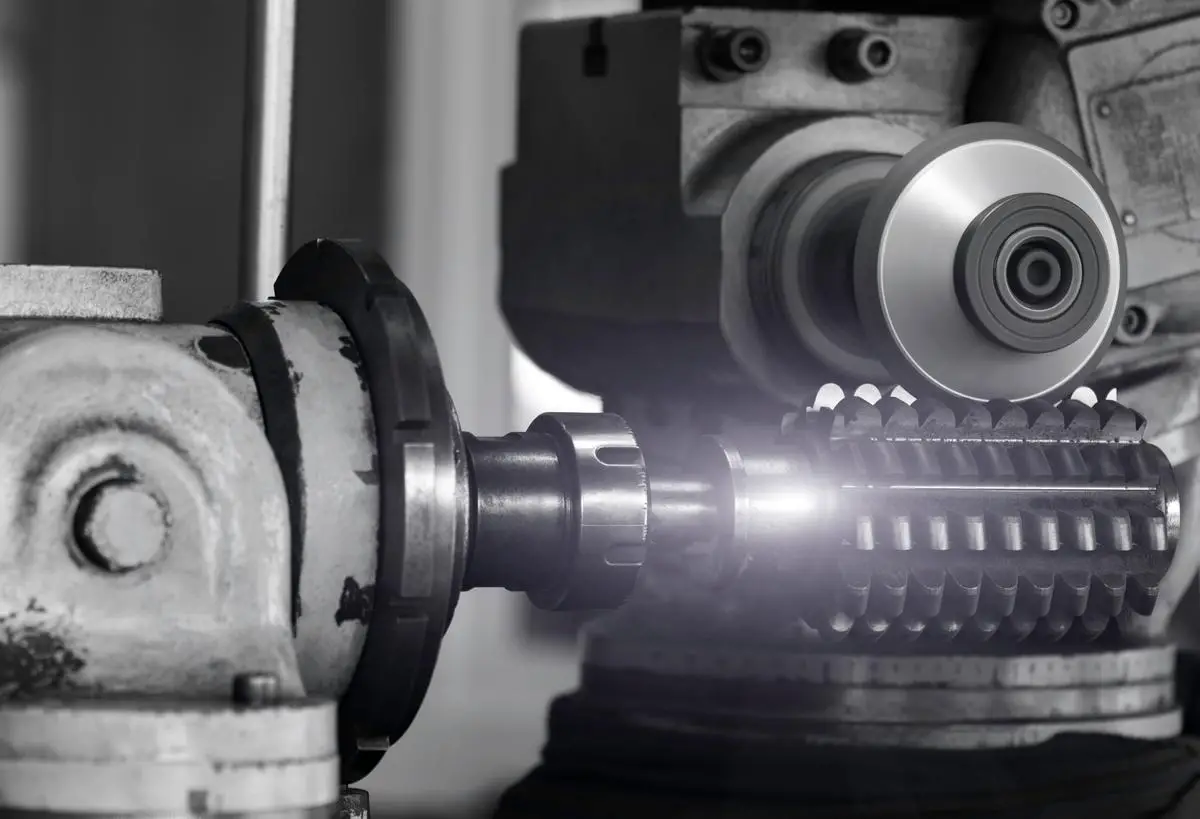

Traditional gear hobs no longer suffice for the requirements of the aforementioned process. Therefore, it becomes crucial to utilize a pre-grinding hob equipped with a contact angle during the hobbing phase. The distinguishing element of a pre-grinding hob, compared to a standard one, lies in the top of its cutting teeth, which employs a cutting edge with a contact angle, as depicted in the figure below.

At the root of the gear tooth, a certain amount of root undercutting is performed. This is intended to pre-form the root part of the gear being processed and to remove most of the surplus from the tooth surface, leaving an even margin for precision machining at the tooth thickness. After carburizing and quenching, grinding of the tooth root is no longer necessary.

(2) Requirements for Gear Tooth Shape Before Grinding:

(3) Improvements to Pre-grinding Hobbing Cutters

The early use of pre-grinding hobbing cutters exhibited the following issues:

After long-term targeted research and analysis, we identified the problems as:

Due to the insufficiency in the formation of the envelope line of the original pre-grinding hobbing cutters, we proposed the idea of redesigning them, approaching from the following aspects:

The above requirements were agreed upon with domestically technically capable tool manufacturers, jointly developing and producing a new type of pre-grinding hobbing cutter suitable for heavy-duty gear processing. Not only did the new pre-grinding hobbing cutter completely resolve the previous issues, but it also resulted in a very smooth root area of the processed gear, yielding excellent results.

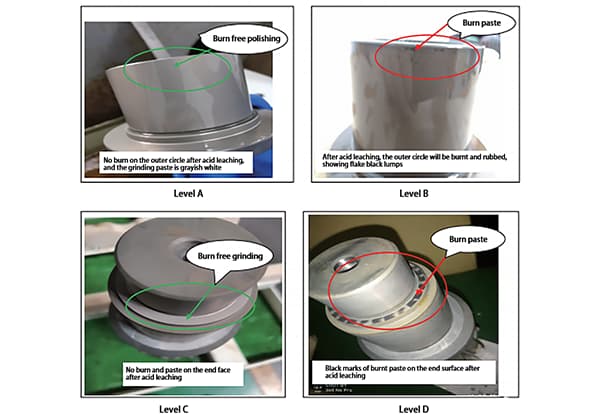

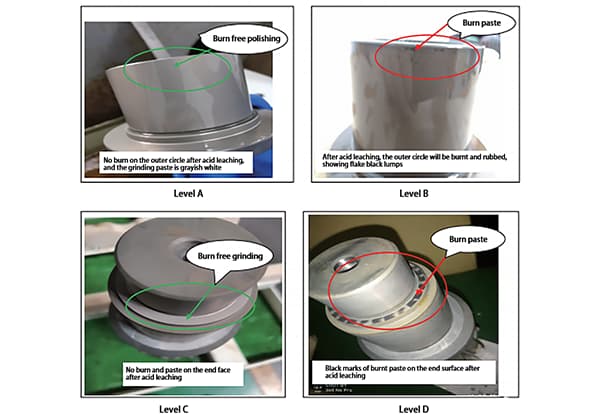

(4) Grinding cracks and burn marks are impermissible in gear grinding.

The process of gear tooth fracture typically begins with the formation of minute fatigue cracks, which gradually expand. Therefore, both domestic and international gear standards specify: no grinding cracks or burn marks are allowed on the hardened gear surface after gear grinding.

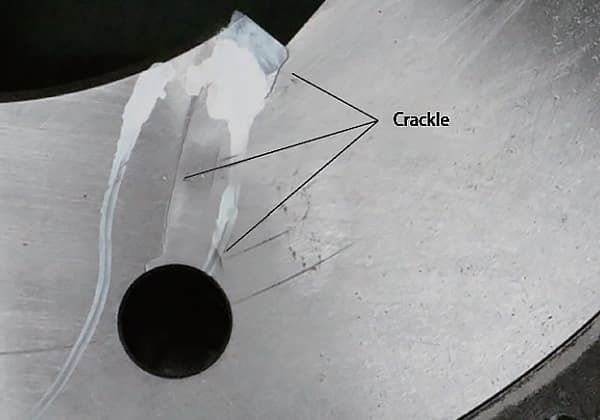

Grinding cracks are the most typical surface cracks. Their vertical depth generally does not exceed 0.5 mm, with shallow ones only reaching 0.010-0.020 mm. Though sometimes they may exceed 1 mm, this is relatively rare.

The consensus both domestically and internationally is that grinding cracks are caused when the grinding tensile stress exceeds the material’s fracture strength. The factors that directly affect the grinding tensile stress are:

(1) Heat treatment:

Grinding cracks in hard tooth surface gears mostly occur in parts that have undergone carburizing, quenching, and low-temperature tempering. Therefore, the quality of heat treatment is closely related to grinding cracks and is a very important factor.

(2) Grinding process:

Since grinding cracks occur during the grinding process, the grinding technology is an essential factor that cannot be ignored.

Materials that are more sensitive to grinding cracks are more prone to crack formation during grinding. Reducing the sensitivity of the material to grinding cracks decreases the likelihood of crack occurrence.

Materials like 20CrMnTi and 20Cr2Ni4A are more sensitive to grinding cracks, and this sensitivity varies with different carburizing heat treatment specifications.

Therefore, it can be appropriately regulated and reduced by changing carburizing, quenching, and tempering processes. The following measures are adopted for this reason:

(1) Reduce the quenching temperature of carburized parts: For gears made from 20CrMnTi, carburize at 930°C, quench directly after carburization, and when the quenching temperature decreases from 860°C to 830°C, serious grinding cracks can be eliminated without changing the grinding conditions.

(2) The surface carbon concentration should be appropriate, controlled within the range of 0.7% to 0.9%. The carbon concentration gradient should be gradual, ensuring good surface strength and stress distribution.

The carbon content of heavy-duty gears should be controlled at the lower limit, which facilitates controlling the size and shape of carbides. When the carbon content is controlled at the upper limit, it will enhance the tendency to form residual austenite, increase the carbide, surface oxidation, and the trend of reducing tooth root strength.

According to relevant data, the United States has controlled the surface carbon concentration of heavy-duty gears to about 0.65%.

(3) The less sufficient the tempering, the higher the sensitivity to grinding cracks. Therefore, thorough tempering is essential to enhance the ductility of the carburized hardened surface, allowing the residual stresses to balance or reduce, and improve the distribution of surface stresses. This, in turn, lowers the likelihood of grinding cracks.

(4) Control the amount of residual austenite to prevent structural transformation during gear grinding, which leads to significant structural stress. Strictly limit the residual austenite to within 25%, and for crucial gears, it should be controlled within 20%.

(5) The main focus is on controlling the size, quantity, shape, and distribution of carbides to achieve a dispersed distribution of fine-grained carbides. This enhances the fracture strength of the material and reduces brittleness.

(6) Control the level of martensite to obtain cryptocrystalline and fine needle-like martensite, avoiding the formation of coarse needle-like martensite, thereby reducing the sources of cracks and improving the fracture strength of the material. The optimal martensite level is 3.

(7) Implement necessary process measures to control the deformation of heat treatment, reducing the grinding allowance.

Literature indicates that the average temperature in the contact area between the grinding wheel and the gear surface typically ranges from 500-800°C, with the temperature at the grinding points reaching up to 1000°C.

Furthermore, over 80% of this heat is transferred into the gear. The substantial heat generated during gear grinding leads to significant thermal stress and thermally induced expansion and contraction in the gear surface’s grinding area.

If this heat is not effectively controlled, the gear surface can easily develop grinding cracks and burns.

Therefore, the emphasis of machining’s technological measures will focus on minimizing and controlling the heat generated from grinding.

(1) Lower the surface roughness during the rough hobbing phase to control it between Ra3.2 and Ra3.6.

(2) Strictly regulate the remaining nominal size during rough hobbing, it’s not permissible to arbitrarily increase the grinding allowance.

(3) After heat treatment, rigorously adjust according to the prescribed position and permissible range to minimize the error from thermal distortion as much as possible.

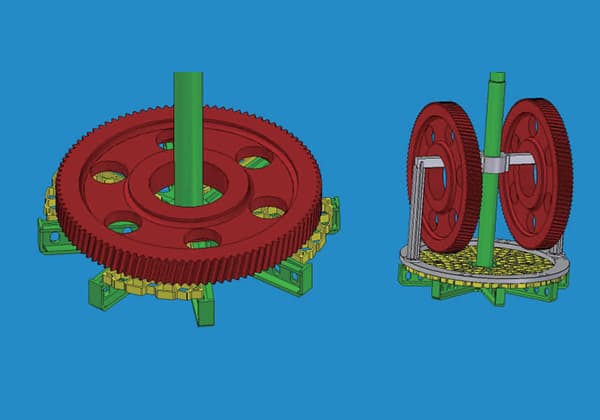

(4) Prior to grinding, it’s imperative to use roll-cutting technology on the hardened tooth surface for tooth scraping. This ensures a uniform grinding allowance, reducing it to the greatest extent possible, thereby minimizing grinding heat.

(5) Select and match cutting quantities rationally. The guiding principles should be higher wheel speeds, faster strokes, and appropriate feed. According to foreign data: the rough grinding phase of the tooth surface is the crucial moment for the formation of grinding cracks. A vast majority of grinding cracks occur at this stage. Special attention should be paid during this phase.

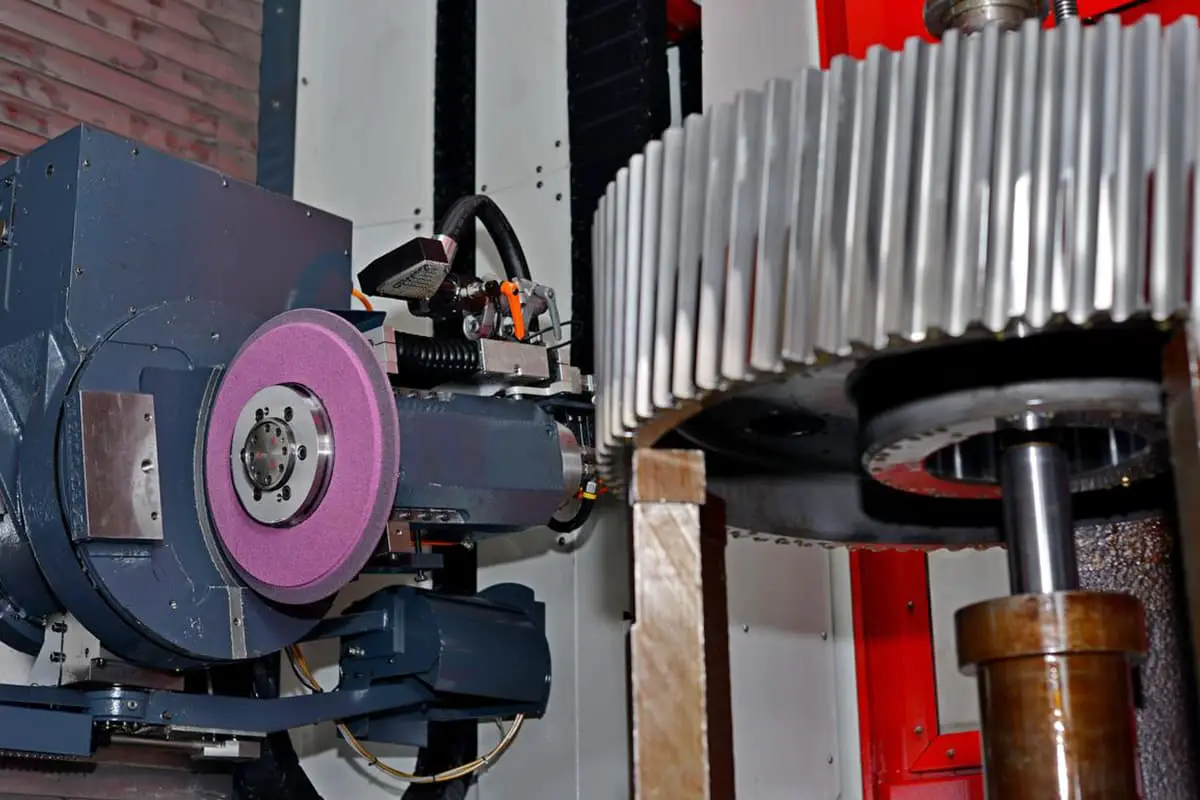

(6) Selecting the grinding wheel is a crucial step in the tooth grinding process. An appropriate choice of grinding wheel greatly impacts the precision and efficiency of tooth grinding. Improper choice of the wheel’s hardness, grain size, or structure can easily lead to surface burn and grinding cracks. Therefore, the wheel should be chosen considering the following aspects:

When grinding cracks appear on the hardened gear surfaces, the causes of these cracks should first be analyzed. Then, based on the working conditions, the following treatments should be applied:

(1) Secondary Tempering Method

By appropriately extending the tempering time for carburized quenched parts, increasing the tempering temperature, and increasing the number of temperings, sufficient tempering can be achieved to eliminate and reduce grinding cracks. The specific approach is as follows:

Due to the simplicity and effectiveness of these methods, they are commonly used for preventing and eliminating grinding cracks.

(2) The effects of sufficient tempering are as follows:

(3) Methods for Identifying Adequate Tempering

(4) Considerations During Secondary Tempering

Cracked tooth surfaces are cleaned by scarfing with a hard alloy roller cutter, followed by tooth grinding. This method is primarily used when:

A severe grinding crack occurred in the grinding of a large planetary gear, providing a typical instance of the grinding crack removal method, as detailed below:

(1) Brief introduction to the situation of the large planetary gear with severe grinding cracks:

(2) Implement the following measures:

By implementing the above measures, all severe grinding cracks have been successfully eliminated.