The principle of product structure design is the fundamental concept and guidelines in the design of product structure.

These guidelines ensure that the product structure design is rational.

For both plastic and hardware products, the principles of product structure design encompass the appropriate selection of materials, the choice of a reasonable structure, the simplification of the mold structure, and cost control.

01 Reasonable selection of materials

All products are comprised of materials.

When designing products, the initial step is to consider the selection of materials.

Materials not only affect the product’s function but also influence its cost.

So, how do we choose materials in a rational manner?

(1) Choose Based on the Product’s Application:

The requirements for materials in different applications can vary. For instance,

- For daily consumer electronic products, materials that are strong, easy to treat the surface, resistant to rust and wear, and easy to form such as PC, ABS, PC + ABS for plastic materials, and stainless steel, aluminum, and zinc alloy for metal materials, are preferred.

- In the food industry, materials that are non-toxic and tasteless, low temperature resistant, high temperature resistant, or even non-additive, such as PET for beverage bottles, PPPE for food packaging bags, and PP or PC for drinking cups, are necessary.

(2) Choose Based on the Product’s Market Orientation:

The market positioning of a product also affects material selection. Products are categorized into high-grade, middle-grade, and low-grade based on quality.

- High-grade products require excellent materials.

- Middle-grade products require materials with acceptable performance.

- Low-grade products require materials that minimize cost as much as possible.

(3) Choose Based on the Product’s Function:

Material selection depends on the product’s function. For instance,

- Products that move require materials with wear resistance. Many metal materials are generally wear-resistant, and wear-resistant plastic materials such as PA (nylon) and POM, or rubber materials such as natural rubber, can be used.

(4) Choose Based on the Company’s Requirements:

Every company has its own suppliers, including those for materials. For a single product, there are multiple materials that can fulfill the design requirements, and their prices may vary. The material selection should take into account the specific circumstances of the company.

02 Select reasonable structure

The product structure design should not be overly complex.

In fact, a simpler structure is preferred, as long as it meets the product’s function.

A simpler structure is easier to mold, produce, and assemble, and it reduces the likelihood of problems.

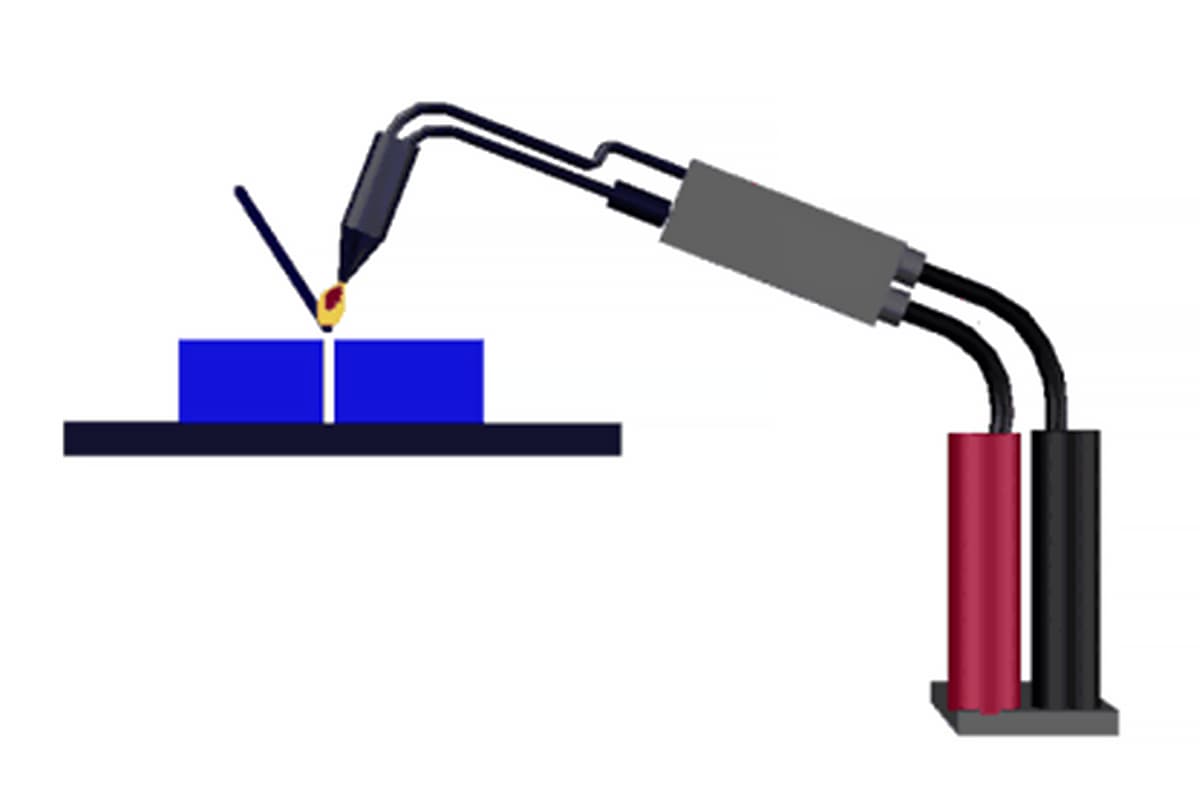

For instance, there are several ways to fix a product’s structure, including screw fixation, buckle fixation, double-sided adhesive fixation, hot-melt fixation, ultrasonic welding fixation, etc.

When choosing these methods, it is recommended to:

- Prefer screw fixation as it is the most reliable and detachable method.

- Use buckle fixation, which is convenient and simple, in combination with screws for better reliability.

- Reserve double-sided adhesive fixation, hot-melt fixation, etc. for specific places where necessary.

In product structure design, redundant structures are not permitted. This means that designing time is wasted, mold processing becomes more challenging, and materials are used unnecessarily.

When designing the product structure, it is important to only include what is necessary and exclude what is not. Every structure should serve a purpose, including every buckle, stiffener, etc.

03 Try to simplify the die structure

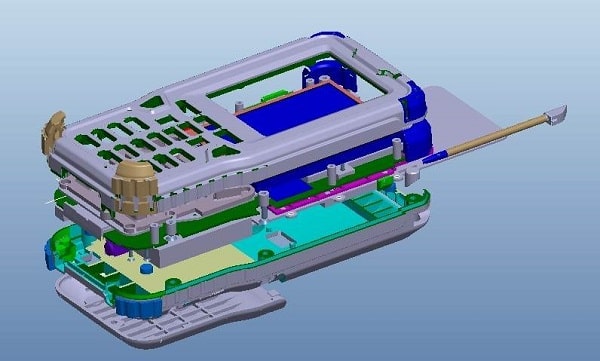

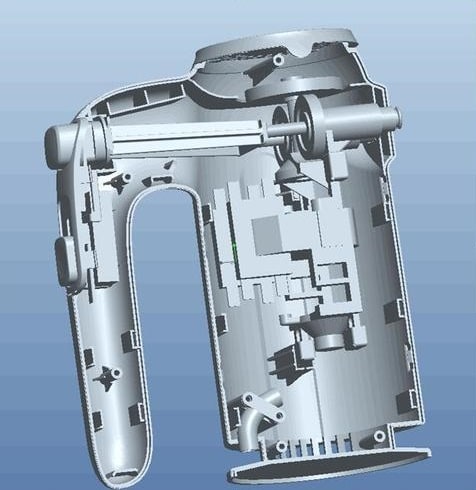

After the product design is completed, a mold is needed to form the product. Even if the product structure design is sound, if the mold cannot be created or is difficult to create, the structure is deemed unsatisfactory.

As a structural engineer, it is crucial to have a basic understanding of molds, including their basic structure, the product’s molding method, and the way out of the mold. This way, the mold structure can be simplified during product design as much as possible.

For instance, undercutting in the die affects normal die output. Sliders and inclined tops are commonly used to resolve the undercutting issue, but this increases the complexity of the die and the cost of producing the die.

In structural design, efforts should be made to handle mold buckles so that the product can be removed from the mold normally. Some internal buckles can be rubbed through or touched through to simplify the mold structure. However, some buckles must be kept and can only be realized by adding a slider or inclined top to the die.

Therefore, in product design, the mold should be simplified as much as possible while still meeting the product’s basic needs.

04 Cost control

Cost is a crucial aspect of the product.

The cost level significantly impacts the company’s profit margin.

Cost control begins at the start of product design.

In product structure design, cost control should be focused on the following areas:

(1) When selecting materials, prioritize low-priced materials while still meeting the product’s function.

(2) In product shape modeling, reduce the number of parts as much as possible while still maintaining the desired appearance.

(3) The structure should be simplified as much as possible during product design to lower the cost of the mold.

(4) Choose a proper fixing method during product structure design to save production and assembly costs.

(5) Adopt appropriate surface treatment methods during the product’s surface treatment, based on the product positioning and appearance requirements, to reduce processing costs.

(6) Utilize the company’s existing materials as much as possible in product structure design and aim to unify material specifications, such as the screw model.