Are you deciding between turret punching and laser cutting for your next project? Understanding their unique benefits and limitations is crucial. This article delves into the capabilities of both techniques, comparing aspects such as precision, speed, flexibility, and cost-efficiency. By the end, you’ll know which method suits your specific needs, whether it’s for simple hole punching or intricate shape cutting.

A laser is a type of light that is generated through the transition of atoms, molecules, or ions. Unlike typical light sources, laser light is primarily based on stimulated emission, resulting in a highly pure color, intense luminosity, and high coherence.

In laser cutting machines, the beam is focused into a small spot via the lens in the cutting head. This spot has a high power density, and the cutting head is positioned along the z-axis.

During the cutting process, the heat input from the beam surpasses the heat reflected, conducted, or diffused by the material, causing it to rapidly heat up to its melting and vaporization temperature.

A high-speed airflow then removes the melted and vaporized material, either in a coaxial or non-coaxial direction, creating cuts in the material.

With the relative movement between the focus and the material, a continuous and narrow slit is formed, completing the material cutting process.

The process parameters (such as cutting speed, laser power, and gas pressure) and motion trajectory are controlled by a numerical control system during slit cutting. The slag at the slit is also removed by a pressurized auxiliary gas.

However, the laser beam has a certain divergence angle and is “conical” in shape, which means that its height can change (equivalent to the change in the laser cutter’s optical path length). This results in a change in the beam cross-sectional area on the focusing lens surface.

Additionally, light has wave-like properties, leading to diffraction. Diffraction causes the beam to expand laterally as it travels, which is a common phenomenon in all optical systems and limits their performance.

The Gaussian beam cone and light wave diffraction cause the beam diameter on the lens surface to change as the optical path length changes. This leads to changes in focus size and depth, but has little effect on focus position.

During continuous processing, if the focus size and depth change, it can have a significant impact on the processing outcome. For example, it can result in inconsistent cutting seam width, incomplete cutting, or material ablation under the same cutting power.

This is a disadvantage of the laser cutting machine principle.

A CNC turret punch can be utilized for processing all types of sheet metal parts and can automatically complete complex holes and shallow stretching in one operation.

Based on the requirements, holes of varying shapes, sizes, and spacings can be processed automatically.

Large round holes, square holes, waist holes, and a variety of curved contours can also be punched with small dies in stages.

Special processes, such as louvers, shallow stretching, counterbores, flanging holes, stiffeners, and embossing, can also be performed.

Through simple die combination, compared with traditional stamping:

The CNC turret punch boasts high machining precision and stable machining quality.

It has a large processing format, with the capability to complete a 1.5m x 5m format in one operation.

It can perform multi-coordinate linkage and process parts with complex shapes, and can also be used for shearing and forming.

When machining parts need to be changed, only the NC program needs to be altered, which saves time in production preparation.

The punch itself has high precision and rigidity, allowing for optimal processing conditions and high productivity.

The punch has a high level of automation, reducing labor intensity.

It is simple to operate, and with basic computer knowledge, training for 2 to 3 days is sufficient.

The CNC turret punch saves on mold costs and allows for low cost, short cycle processing of small batches and diverse products.

It has a wide processing range and capacity, adapting to market and product changes in a timely manner.

Processing mode of servo turret CNC punch:

(1) Single Punching: The punching process is completed in one operation, including linear distribution, arc distribution, circumferential distribution, and punching of grid holes.

(2) Continuous Blanking in the Same Direction: The method of partial overlapping processing using a rectangular die can be used to produce long holes and trimming.

(3) Multi-Direction Continuous Blanking: The process of machining large holes using small molds.

(4) Nibbling: Continuous punching of arcs using small round dies in small steps.

(5) Single Forming: A one-time shallow stretching process, based on the mold shape.

(6) Continuous Forming: Forming processes that are larger than the die size, such as large louvers, rolling ribs, and rolling steps.

(7) Array Forming: Machining multiple identical or different workpieces on a large plate.

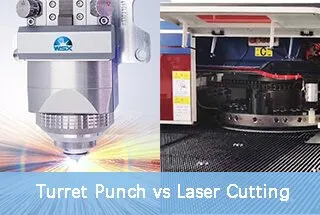

Both laser cutting and CNC punching are essential processing methods in production and processing.

In order to choose the most efficient and cost-effective method, it is important to understand the unique characteristics of each.

Based on my experience, the two methods have the following characteristics and differences:

CNC punching mainly cuts straight lines, square holes, round holes, and oblong holes, with a simple and fixed pattern.

It is primarily used for processing carbon steel plates and aluminum plates with a thickness of less than 6mm.

CNC punching is not recommended for stainless steel plates with a thickness greater than 2mm as the material has high viscosity and hardness, leading to frequent material jumping and tool sticking, and high mold consumption.

Overall, CNC punching has a fast processing speed with fixed dies. If a new mold is required, the development cycle is at least three weeks and the cost is high.

The degree of flexibility is low, removing burrs at the connection point is challenging, and the knife joint mark is noticeable.

For parts with a length less than 500mm, the machining accuracy is approximately +/ – 0.10mm.

Laser cutting is more flexible and has a faster cutting speed and higher production efficiency.

It has a shorter production cycle, with no deformation during processing and no mold required.

Any shape can be precisely formed in one operation. For parts with a length less than 500mm, the machining accuracy is approximately +/ – 0.05mm.

However, the cost of simple graphic laser cutting is higher compared to punching. The slag around the cutting line affects the surface quality.

Three-dimensional special shapes, such as rolling ribs, knockout holes, and louvers, cannot be produced using a laser cutting machine.

In actual production, it is necessary to choose the appropriate processing method based on the part drawing in order to achieve the best results.