Laser welding can join a remarkable variety of materials, but which ones truly excel? This article explores the specifics, covering everything from common metals like carbon steel and aluminum to more complex materials such as plastics and copper alloys. Readers will discover the unique challenges and solutions for each material, providing essential insights for selecting the right materials and techniques for their laser welding projects.

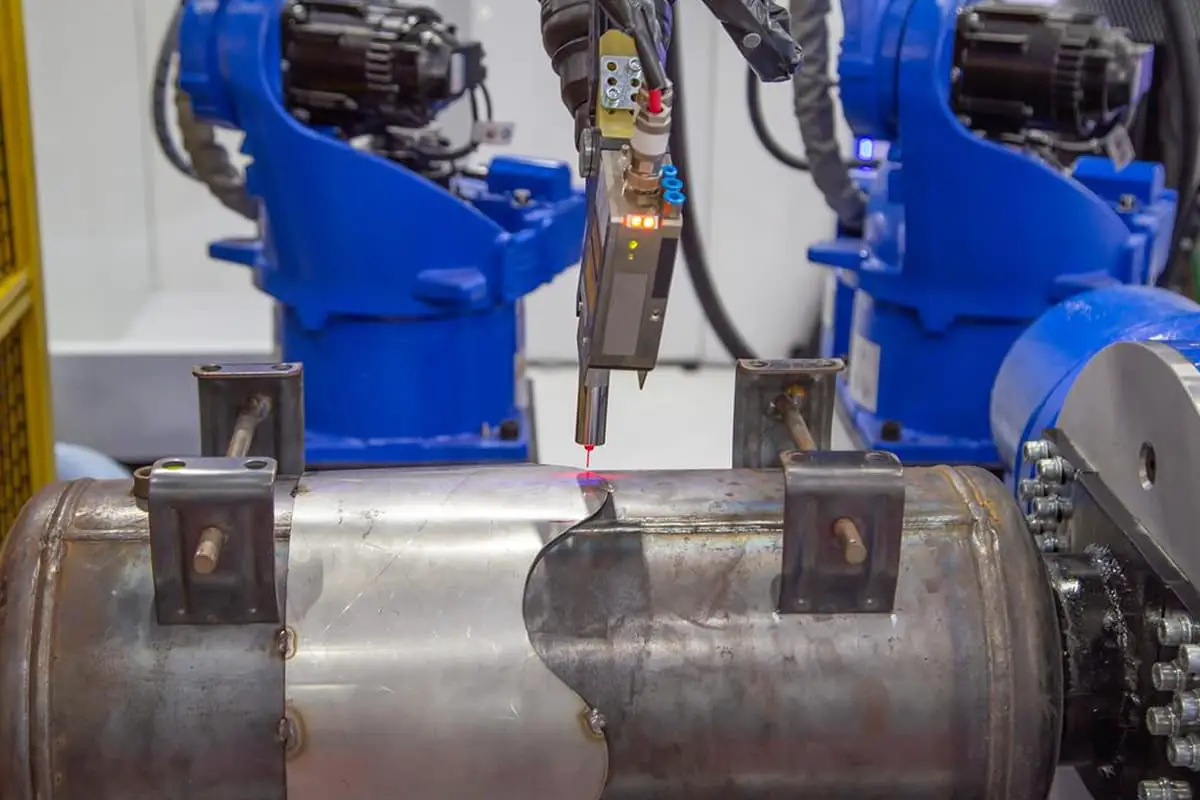

Laser welding is the process of using high-energy laser pulses to locally heat a small area of a material. The energy of the laser radiation is transferred to the material’s interior through heat transfer, causing the material to melt and form a specific molten pool, thus achieving the purpose of welding.

A laser welding machine is a device used for laser material processing. Based on its mode of operation, it can be classified into four types: laser mold welding machine, automatic laser welding machine, laser spot welding machine, and optical fiber transmission laser welding machine.

The laser welding machine can be used for welding die steel of S136, SKD-11, NAK80,8407,718,738, H13, P20, W302, 2344 and other models, and the welding effect is good.

Carbon steel can be effectively welded using a laser welding machine, and the quality of the welding is dependent on the presence of impurities. To achieve good welding quality, preheating is necessary when the carbon content exceeds 0.25%.

When welding steels with different carbon contents together, the welding torch should be slightly angled towards the low-carbon material to ensure the quality of the joint.

Due to the rapid heating and cooling speed of laser welding machines, as the carbon content increases, the susceptibility to welding cracks and notches also increases.

Both medium and high carbon steels and common alloy steels can be welded well using a laser, but preheating and post-weld treatment are necessary to relieve stress and prevent cracks.

In general, welding stainless steel is easier to achieve high-quality joints than with traditional welding methods.

The high welding speed and small heat-affected zone of laser welding reduce the risks of overheating and the negative effects of the large linear expansion coefficient during stainless steel welding, resulting in welds that are free of defects such as pores and inclusions.

Compared to carbon steel, stainless steel is easier to achieve deep, narrow penetration welds due to its low thermal conductivity, high energy absorption, and efficient melting.

Welding thin plates with low-power lasers can result in joints that are visually appealing with smooth, beautiful welds.

Welding copper and copper alloys can result in problems with incomplete fusion and penetration, thus requiring the use of energy-concentrated and high-power heat sources and preheating measures.

When the workpiece is thin or has low structural stiffness and without measures to prevent deformation, large deformations can occur after welding. Additionally, when the welded joint is subjected to significant rigid constraints, welding stress may develop.

Thermal cracking is also a common issue when welding copper and copper alloys.

Porosity is a frequent defect in copper and copper alloy welding.

Laser welding technology can be applied to almost all thermoplastics and thermoplastic elastomers, including common materials such as PP, PS, PC, ABS, polyamide, PMMA, polyoxymethylene, PET, and PBT.

However, other engineering plastics, such as polyphenylene sulfide (PPS) and liquid crystal polymers, cannot be directly welded using laser technology due to their low laser transmittance.

In general, carbon black is added to the bottom material to increase its ability to absorb energy, allowing it to meet the requirements for laser transmission welding.

The primary challenge in laser welding of aluminum and its alloys is their high reflectivity to 10.8µm CO2 laser beams.

Aluminum is an excellent conductor of both heat and electricity, and its high density of free electrons makes it an effective reflector of light.

With an initial surface reflectivity exceeding 90%, deep penetration welding must start with less than 10% of the input energy, requiring high input power to ensure the necessary power density at the beginning of welding. This results in the formation of small holes.

Mg alloys have a density that is 36% lower than Al, making them highly attractive as high-specific strength materials.

To explore their welding potential, tests using pulsed YAG lasers and continuous CO2 lasers were conducted.

For the AZ31B-H244 alloy (3.27% Al, 0.79% Zn) with a plate thickness of 1.8mm, the best welding conditions with minimal defects were found to be an average power of 0.8 kW, pulse duration of 5 ms, frequency of 120 Hz, speed of 300 mm/s, and a focus size of 0.42 mm.

Continuous CO2 laser welding was found to produce good penetration welds.

For laser welding of low alloy high-strength steels, proper selection of welding parameters can result in joints with mechanical properties equivalent to the base metal.

HY-130 steel is a representative low alloy high-strength steel that, after quenching and tempering, boasts high strength and resistance to cracking.

Using conventional welding methods, the weld and heat-affected zone (HAZ) structures exhibit a mixture of coarse grains, some fine grains, and the original structure.

However, the toughness and resistance to cracking in the joint are inferior to the base metal, and the weld and HAZ structures are particularly susceptible to cold cracks in their as-welded state.

Laser welding can be used to join a wide range of materials and can even be used to weld dissimilar metals.

Studies have shown that laser welding can be performed between various dissimilar metal combinations, such as copper-nickel, nickel-titanium, copper-titanium, titanium-molybdenum, brass-copper, and low carbon steel-copper, under certain conditions.