Ever wondered how your car parts are made with such precision? Dive into the fascinating world of die casting—a process where molten metal is shaped under high pressure and speed. This article will unveil the secrets behind this technique, explaining how it ensures high-quality, durable products. Get ready to explore the key elements and parameters that make die casting a cornerstone of modern manufacturing!

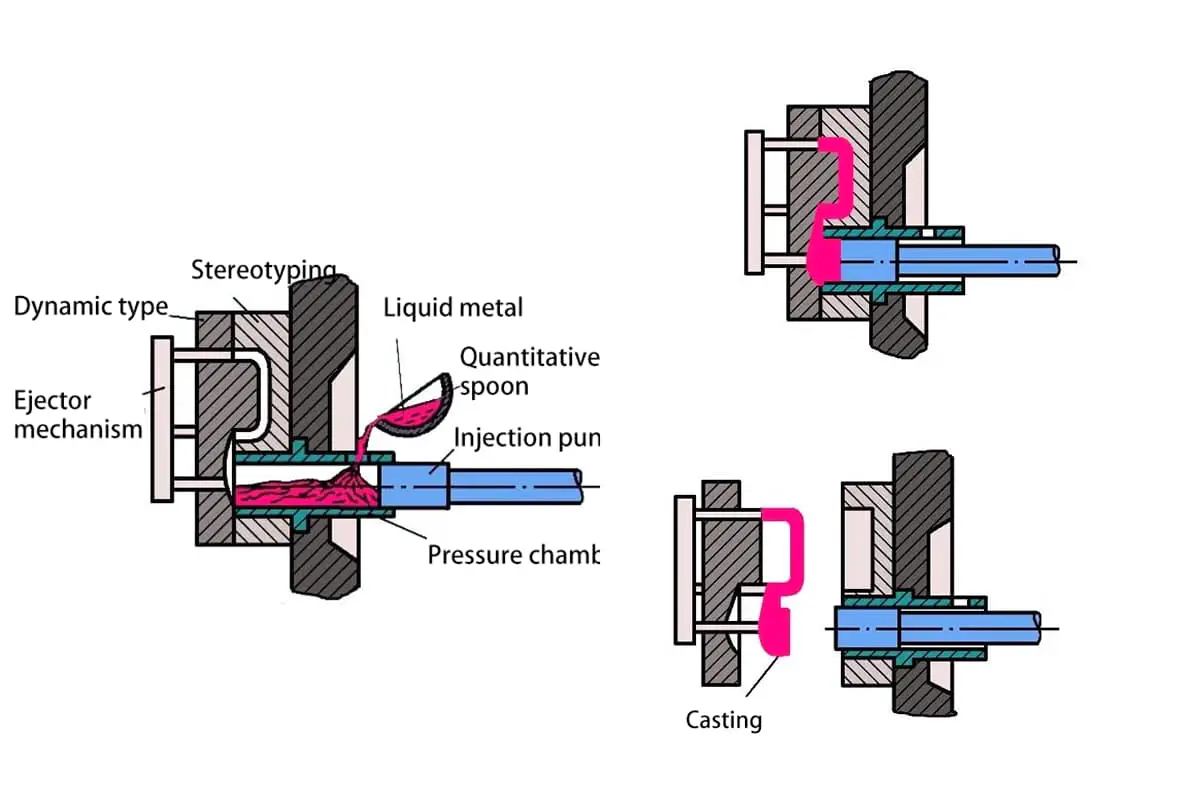

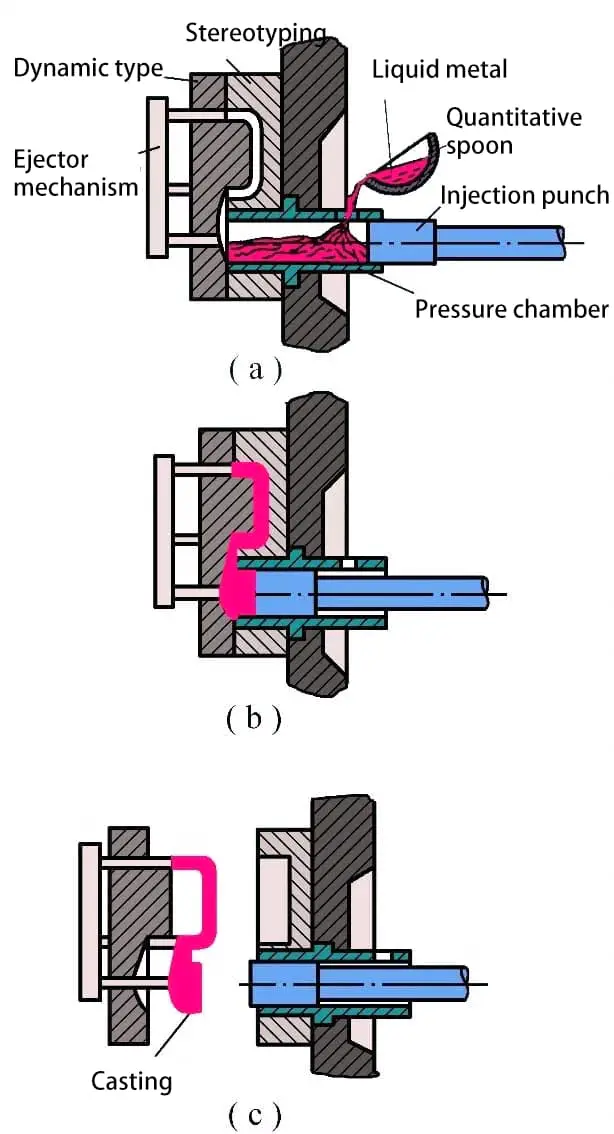

The die casting process incorporates three major elements: machinery, molds, and alloys. It unifies pressure, speed, and time in a single process, and is primarily used for hot metalworking. The presence of pressure differentiates die casting from other casting methods.

Die casting is a rapidly developing technique in modern metalworking processes, and it’s a special casting method that minimally requires cutting.

It involves filling a mold with molten metal under high pressure and speed, and then the metal crystallizes and solidifies under this high pressure to form the casting. High pressure and high speed are the main characteristics of die casting.

The commonly used pressure is tens of megapascal, the filling speed (inner sprue speed) is approximately 16 to 80 meters per second, and the time for the molten metal to fill the mold cavity is extremely short, approximately 0.01 to 0.2 seconds.

The method of manufacturing products in this way has become an essential part of our country’s casting industry due to its high production efficiency, simplified processes, superior casting tolerance levels, good surface roughness, high mechanical strength, and the ability to eliminate a large number of machining procedures and equipment, thereby saving raw materials.

Die casting is a process that organically combines and comprehensively applies the three major elements of a die-casting machine, die-casting mold, and alloy. During die-casting, the process of metal filling the mold cavity is a unified process involving factors such as pressure, speed, temperature, and time.

Simultaneously, these factors interact with and restrict each other, complementing and supporting one another. Only through the correct selection and adjustment of these factors to achieve harmony and consistency can the desired results be obtained.

Therefore, not only should the processability of the casting structure, the advancement of the die-casting mold, the performance and structural excellence of the die-casting machine, and the adaptability of the chosen die-casting alloy and standardization of the melting process be emphasized during the die-casting process, but the significant role of process parameters such as pressure, temperature, and time on the quality of the casting should also be taken into account. Effective control of these parameters should be prioritized during the die-casting process.

The injection force is the force that drives the motion of the injection piston in the injection mechanism of the die casting machine. It is a main parameter reflecting the functions of the die casting machine. The magnitude of the injection force is determined by the cross-sectional area of the injection cylinder and the pressure of the working fluid.

The calculation formula for the injection force is as follows:

Pinjection force = Pinjection cylinder × π × D²/4

Where:

Specific Pressure

The pressure exerted on the molten metal in the pressure chamber per unit area is called the specific pressure. The specific pressure is also the result of the conversion of the ratio of the injection force to the cross-sectional area of the pressure chamber.

Its calculation formula is as follows:

Pspecific pressure = Pinjection force/Fpressure chamber cross-sectional area

Where:

That is, Fpressure chamber cross-sectional area = πD²/4. Here D(m) is the diameter of the pressure chamber.

Effect of Pressure

(1) Impact of specific pressure on the mechanical properties of castings

As the specific pressure increases, the crystalline structure becomes finer, the fine crystal layer thickens, the surface quality improves due to improved filling characteristics, the impact of air holes is reduced, and thus the tensile strength increases, but the elongation decreases.

(2) Impact on filling conditions

When the alloy melt fills the mold cavity under high specific pressure, the alloy temperature rises, the fluidity improves, which is beneficial to the improvement of the casting quality.

Selection of Specific Pressure

(1) Consideration based on the strength requirements of the castings

Divide the castings into those with strength requirements and those with general requirements. For those with strength requirements, they should have good densification. This requires a high boosting specific pressure.

(2) Consideration based on the wall thickness of the castings

In general, when die casting thin-walled castings, the flow resistance in the mold cavity is greater and the gating system also has a thinner thickness, hence it has greater resistance.

Therefore, a larger filling specific pressure is needed to ensure the required gating speed. For thick-walled castings, on one hand, the selected gating speed is lower, and the metal solidification time is longer, so a smaller filling specific pressure can be used; on the other hand, for the casting to have a certain densification, a sufficient boosting specific pressure is needed.

For complex-shaped castings, a higher filling specific pressure should be used. In addition, factors such as the type of alloy, the size of the gating speed, the power of the die casting machine’s clamping ability, and the strength of the mold should all be appropriately considered. The size of the filling specific pressure is mainly calculated based on the selected gating speed.

As for the size of the boosting specific pressure, it can be selected based on the type of alloy, referring to the values in the table below. When the venting conditions in the mold cavity are good and the ratio of the thickness of the gating system to the wall thickness of the casting is appropriate, a lower boosting specific pressure can be used.

However, the worse the venting conditions and the smaller the ratio of the thickness of the gating system to the wall thickness of the casting, the higher the boosting specific pressure should be.

Recommended Boosting Specific Pressure Range Table

| Part Type | Aluminum Alloy | Zinc Alloy | Brass |

| Parts Under Light Load | 30-40 MPa | 13-20 MPa | 30-40 MPa |

| Parts Under Heavy Load | 40-80 MPa | 20-30 MPa | 40-60 MPa |

| Parts with Large Sealing Surface and Thin Walls | 80-120 MPa | 25-40 MPa | 80-100 MPa |

Definition

During the die-casting process, at the end of the filling phase and the transition to the pressure increase phase, the relative pressure (boost pressure) acting on the solidifying metal, transmitted through the metal (casting pouring system, overflow system) to the mold cavity wall surface, is known as the mold expansion force (also referred to as back pressure).

The mold clamping force (also known as closing force) is an important parameter to be determined first when choosing a die-casting machine.

Calculation Method

When the mold expansion force acts on the parting surface, it is referred to as the parting surface expansion force. When it acts on the various sidewalls of the mold cavity, it is known as the sidewall expansion force.

The mold expansion force can be expressed as follows:

Pexpansion force = Pboost pressure × Aprojected area

Where:

Under normal circumstances, the mold clamping force must be greater than the calculated mold expansion force.

Otherwise, during the hydraulic ejection of the molten metal, the mold parting surface will expand, causing metal splashing and preventing the establishment of pressure in the mold cavity. This leads to difficulty in ensuring casting dimensional tolerance, or even difficulty in forming.

The mold clamping force should generally meet the requirements of the following formula:

Pclamping force ≥ K × Pexpansion force

Where:

1. Usually, there are two types: punch speed and internal sprue speed.

2. For slow injection, the punch pushes the molten metal to the internal sprue at 0.3 meters/second.

3. For fast injection, the internal sprue fills the mold cavity at 4-9 meters/second. Enhancing the injection speed can convert the function into thermal energy, improving fluidity, which is beneficial for eliminating flow marks and cold laps, and improving mechanical properties and surface quality.

Selection and consideration factors for injection speed:

1. Thermal conductivity and specific heat, solidification temperature range.

2. If the mold temperature is low, the speed can be low; otherwise, the speed can be high.

3. Complex castings use high injection speed.

Internal sprue speed is 15-70 meters/second (for molten metal).

4. The relationship between punch injection speed and internal sprue speed: the higher the punch injection speed, the higher the molten metal sprue speed.

1. Direct sprue speed is 15-25 meters/second.

2. Cross sprue speed is 20-35 meters/second.

3. Internal sprue speed is 30 to 70 meters/second for a wide gate.

4. For thin castings less than 3 millimeters, the internal sprue speed is 38-46 meters/second.

5. For thick castings 5 millimeters, the internal sprue speed is 46-40 meters/second.

6. For thicker castings more than 5 millimeters, select an internal sprue speed of 47-27 millimeters/second.

Adjustment methods: adjust punch injection speed, change chamber diameter, alter internal sprue cross-sectional area.

1. Die-casting parameter tester, first stage, second stage, and boost transition point time.

2. Impact of the boost starting point on die-casting quality: After the first stage starts to fill 80%, switch to the second stage and boost starting transition point time, and finally maintain pressure, otherwise it will affect the quality.

3. The impact of punch wear and tear on die casting parameters;

4. Analysis of the causes of wear and tear on the injection chamber and punch: The clearance between the injection chamber and the punch is less than 0.1 millimeters, back and forth friction between the punch and the chamber generates high temperatures leading to easy damage.

Chamber diameter becomes larger, punch becomes smaller, punch is stuck with aluminum chips, affecting chamber transmission speed and pressure.

Therefore, the punch should use high-temperature-resistant lubricating oil, the injection rod must have cooling water, and at the same time, the punch material must be chosen, generally choosing ductile iron or beryllium bronze.