What makes a material bend without breaking? The elastic modulus is key, influencing how materials respond under stress. This article explores five critical factors affecting the elastic modulus: alloy elements, heat treatment, strain hardening, cold plastic deformation, and temperature. Readers will gain insights into how these variables impact material properties, essential for engineering applications.

The interatomic force depends on the metal atom itself and the lattice type, so the elastic modulus mainly depends on the nature of the metal atom and the lattice type.

Although solute elements can change the lattice constant of the alloy, for common metal materials, the alloy elements have little effect on the lattice constant and thus have little effect on the elastic modulus.

The elastic modulus values of alloy steel and carbon steel are quite close, and the difference is not more than 12%.

Heat treatment has little effect on elastic modulus, for example, grain size has no effect on elastic modulus;

The size and distribution of the second phase have little influence on the elastic modulus;

Although the elastic modulus decreases after quenching, it returns to the state value before annealing after tempering.

However, after heat treatment (quenching + tempering), the elastic modulus of spring steel (60Si2MnA) changes little, while the shear modulus changes significantly after tempering at different temperatures.

If this is not considered in the design, it may cause certain errors.

For 60Si2MnA material, heat treatment has little effect on e, but g has obvious change.

According to the relationship between shear modulus, elastic modulus and Poisson’s ratio: G=E/(2(1+υ)), it can be concluded that heat treatment will affect υ value.

However, whether this relationship is universal remains to be explored.

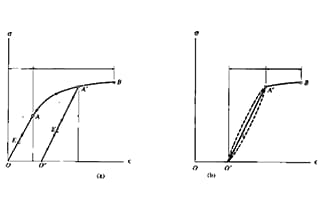

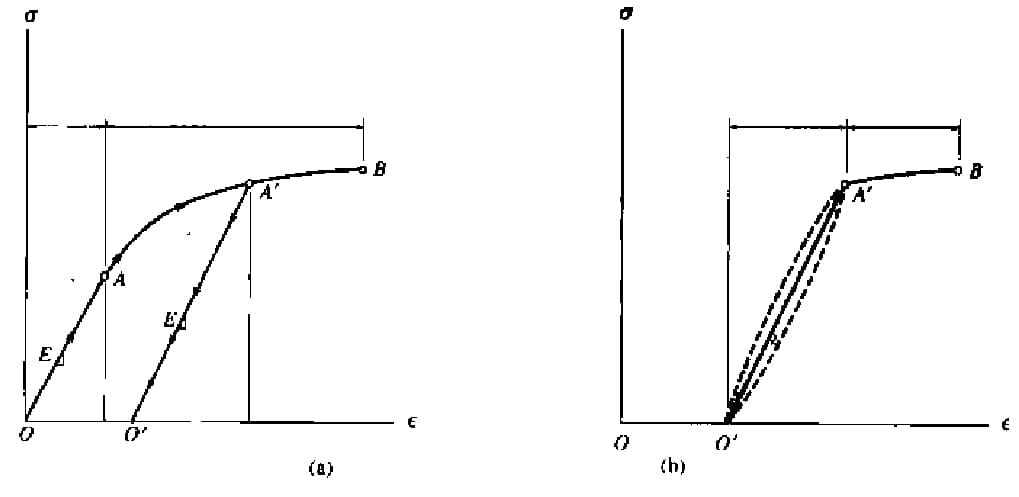

If the test piece is a plastic material, which is loaded to the plastic stage and then unloaded, when the material returns to the equilibrium state, the elastic strain will disappear, while the plastic strain will not disappear, resulting in permanent deformation of the material, as shown in Fig. a.

This process is called strain hardening or cold work hardening.

Thus, although the proportional limit is increased, the plasticity is reduced to a certain extent and the brittleness is increased.

It can be seen from figure a that before and after strengthening, the straight line of the linear section of the curve tends to be parallel, the slope is the same, and the elastic modulus is the same.

In fact, the specimen will lose some heat or energy when unloaded from point a ‘and then loaded to the same point.

Therefore, the curves of loading and unloading process do not coincide.

As shown by the dotted line in Fig. b, there will be a mechanical hysteresis zone.

When selecting damper materials for vibrating structures or mechanical equipment, the mechanical hysteretic characteristics should be taken into account.

Schematic diagram of material strengthening process

Cold plastic deformation makes the elastic modulus slightly lower, generally 4% ~ 6%, which is related to the residual stress.

When the amount of plastic deformation is large, the elastic modulus is anisotropic due to the deformation, and the elastic modulus along the deformation direction is the largest.

The change of material elastic modulus caused by this cold plastic deformation will affect the cold forming accuracy of precision parts.

With the increase of temperature, the distance between atoms increases and the elastic modulus decreases.

When carbon steel is heated, the elastic modulus decreases by 3% ~ 5% for every 100 ℃ increase, but the elastic modulus of steel changes little in the range of – 50 ℃ ~ 50 ℃.

Because elastic deformation propagates in the medium at the speed of sound, the speed of sound in the metal medium is quite large, such as 4982m / s in steel;

In the ordinary pendulum impact test, the absolute deformation rate is only 4 ~ 5.5m/s, and even in the high-speed impact test, the deformation rate is within 103m / s.

Under such impact load, the elastic deformation can always follow the change of external impact force, so the strain rate has no effect on the elastic behavior and elastic modulus of metal materials.

In modern machines, the strain rate of various parts ranges from 10-6 to 106s-1.

For example, the strain rate of static tensile test is 10-5 ~ 10-2s-1 (referred to as quasi-static strain rate), and the strain rate of impact load is 102 ~ 104s-1, referred to as high strain rate.

In addition, there are medium strain rate tests with strain rate of 10-2 ~ 102s-1, such as drop hammer and rotating flywheel.

The practice shows that when the strain rate is in the range of 10-4 ~ 10-2s-1, the mechanical properties of the material have no obvious change and can be treated as static load.

When the strain load rate is greater than 10-2s-1, the mechanical properties of the material will change significantly, which must take into account a series of changes in mechanical properties caused by the increase of strain rate.

In the plastic deformation stage, the deformation increases slowly with the increase of the loading rate.

Therefore, when the loading rate is very fast, the plastic deformation cannot be fully carried out, which is manifested as the improvement of the elastic limit, yield strength and other micro plastic deformation resistance.

It is also found that the plastic deformation under impact load is concentrated in some local areas, which reflects that the plastic deformation is extremely uneven.

This non-uniformity also limits the development of plastic deformation, making the plastic deformation unable to be fully carried out, resulting in the improvement of yield strength and tensile strength, and the improvement of yield strength is more and the improvement of tensile strength is less.