Have you ever considered the critical role hexagonal head bolts play in engineering? These fasteners, ranging from carbon steel to stainless steel, are essential for countless applications, each type designed for specific forces and conditions. This article offers a detailed weight chart for hexagonal head bolts, ensuring you can choose the right bolt for your project. Dive into the specifications and discover how to optimize your designs with precise weight measurements and material properties, boosting both efficiency and safety in your constructions.

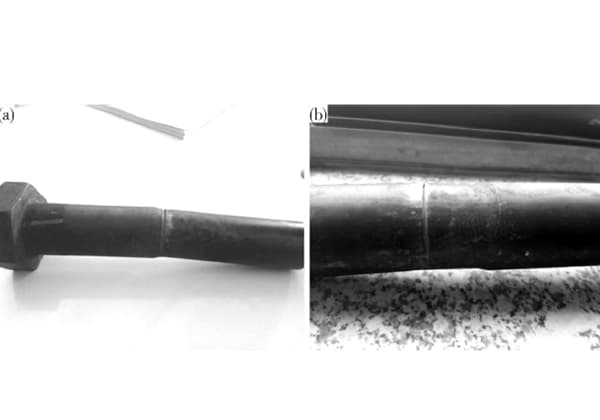

Hexagonal head bolts are divided into two types: external hex bolts and internal hex screws.

Depending on the way they connect and bear force, there are ordinary types and those designed for hinged holes. Bolts for hinged holes must match the size of the hole and are used when subjected to lateral forces.

According to the shape of the head, there are hexagonal, round, square, and countersunk heads among others. Countersunk heads are generally used in places where a smooth surface without protrusions is required after connection, as they can be screwed into the parts. Round heads can also be screwed into parts. Square heads can be tightened more, but their size is quite large. Hexagonal heads are the most commonly used.

Furthermore, to meet the need for locking after installation, there are bolts with holes in the head or the rod. These holes prevent the bolt from loosening when subjected to vibration.

Currently, the market mainly consists of hexagon socket screws made from three types of materials: carbon steel, stainless steel, and copper.

(1) Carbon Steel.

We classify this into low carbon steel, medium carbon steel, high carbon steel, and alloy steel based on the carbon content in the material.

(2) Stainless Steel.

Performance grade: 45, 50, 60, 70, 80. The primary division is into austenitic (18%Cr, 8%Ni), which has good heat resistance, corrosion resistance, and weldability.

A1, A2, A4 Martensite, 13%Cr, has poorer corrosion resistance, high strength, and good wear resistance. C1, C2, C4 Ferritic stainless steel, 18%Cr, has better forgeability and stronger corrosion resistance than martensite.

The current market import materials are mainly Japanese products. The primary division by grade is SUS302, SUS304, SUS316.

(3) Copper.

The commonly used material is brass zinc-copper alloy. The market mainly uses H62, H65, H68 copper for standard parts.

Carbon steel products use the following sheet metal: serial number, type, and optional material. 1. 4.8-grade hexagon screws 1008K 1010 1015K 2. 6.8-grade hexagon screws.

| Specifications (Diameter × Length) | Weight of a Thousand Bolts (Kg) | |

| Without Nuts | With Nuts | |

| M10×30 | 29 | 40 |

| M10×40 | 35 | 46 |

| M10×50 | 41 | 52 |

| M10×60 | 47 | 58 |

| M12×30 | 41 | 57 |

| M12×40 | 49 | 65 |

| M12×50 | 58 | 74 |

| M12×60 | 67 | 83 |

| M12×70 | 76 | 92 |

| M12×80 | 85 | 101 |

| M14×40 | 69 | 94 |

| M14×50 | 81 | 106 |

| M14×60 | 93 | 118 |

| M14×70 | 105 | 130 |

| M14×80 | 117 | 142 |

| M14×90 | 129 | 154 |

| M16×40 | 92 | 126 |

| M16×50 | 106 | 140 |

| M16×60 | 122 | 156 |

| M16×70 | 138 | 172 |

| M16×80 | 154 | 188 |

| M16×90 | 170 | 204 |

| M16×100 | 185 | 219 |

| M20×50 | 183 | 245 |

| M20×60 | 205 | 267 |

| M20×70 | 230 | 292 |

| M20×80 | 255 | 317 |

| M20×90 | 279 | 341 |

| M20×100 | 304 | 366 |

| M20×110 | 329 | 391 |

| M20×120 | 354 | 416 |

| M20×130 | 378 | 440 |

| M22×60 | 250 | 326 |

| M22×70 | 280 | 356 |

| M22×80 | 310 | 386 |

| M22×90 | 339 | 415 |

| M22×100 | 369 | 445 |

| M22×110 | 399 | 475 |

| M22×120 | 429 | 505 |

| M22×130 | 459 | 535 |

| M22×140 | 489 | 565 |

| M22×150 | 519 | 595 |

| M22×160 | 548 | 624 |

| M24×80 | 388 | 500 |

| M24×90 | 424 | 536 |

| M24×100 | 459 | 571 |

| M24×110 | 495 | 607 |

| M24×120 | 531 | 643 |

| M24×130 | 566 | 678 |

| M24×140 | 602 | 714 |

| M24×150 | 637 | 749 |

| M24×160 | 673 | 785 |

| M27×80 | 519 | 687 |

| M27×90 | 564 | 732 |

| M27×100 | 609 | 777 |

| M27×110 | 654 | 822 |

| M27×120 | 699 | 867 |

| M27×130 | 744 | 912 |

| M27×140 | 789 | 957 |

| M27×150 | 834 | 1002 |

| M27×160 | 879 | 1047 |

| M27×170 | 924 | 1092 |

| M27×180 | 969 | 1137 |

| M30×100 | 765 | 999 |

| M30×110 | 820 | 1054 |

| M30×120 | 875 | 1109 |

| M30×130 | 931 | 1165 |

| M30×140 | 986 | 1220 |

| M30×150 | 1042 | 1276 |

| M30×160 | 1098 | 1332 |

| M30×170 | 1154 | 1388 |

| M30×180 | 1210 | 1444 |

| M30×190 | 1266 | 1500 |

| M30×200 | 1322 | 1556 |

| M30×210 | 1378 | 1612 |

| M30×220 | 1434 | 1868 |

| M36×110 | 1246 | 1617 |

| M36×120 | 1326 | 1697 |

| M36×130 | 1406 | 1777 |

| M36×140 | 1486 | 1857 |

| M36×150 | 1566 | 1937 |

| M36×160 | 1646 | 2017 |

| M36×170 | 1726 | 2097 |

| M36×180 | 1806 | 2177 |

| M36×190 | 1886 | 2257 |

| M36×200 | 1966 | 2337 |

| M36×210 | 2046 | 2417 |

| M36×220 | 2126 | 2497 |

| M36×230 | 2206 | 2577 |

| M36×240 | 2286 | 2657 |

| M42×150 | 2223 | 2822 |

| M42×160 | 2332 | 2931 |

| M42×170 | 2441 | 3040 |

| M42×180 | 2550 | 3149 |

| M42×190 | 2659 | 3258 |

| M42×200 | 2768 | 3367 |

| M42×210 | 2877 | 3476 |

| M42×220 | 2986 | 3585 |

| M42×230 | 3095 | 3694 |

| M42×240 | 3204 | 3803 |

| M42×250 | 3313 | 3912 |

| M48×150 | 3005 | 3962 |

| M48×160 | 3147 | 4104 |

| M48×170 | 3289 | 4246 |

| M48×180 | 3431 | 4388 |

| M48×190 | 3573 | 4530 |

| M48×200 | 3715 | 4672 |

| M48×210 | 3857 | 4814 |

| M48×220 | 3999 | 4956 |

| M48×230 | 4141 | 5098 |

| M48×240 | 4283 | 5240 |

| M48×250 | 4432 | 5389 |

| M48×260 | 4574 | 5531 |

| M48×280 | 4858 | 5815 |

| M48×300 | 5142 | 6099 |

| d | S | H | D | Approximate Weight of 1000 Steel Nuts (kg) | |||

| Nominal Size | Tolerance | Nominal Dimension | Tolerance | ||||

| Rough Manufacturing | Semi-Precision Manufacturing | ||||||

| 6 | 10 | -0.36 | 5 | ±0.48 | ±0.38 | 11.5 | 2.317 |

| 8 | 14 | -0.43 | 6 | 16.2 | 5.674 | ||

| 10 | 17 | -0.52 | 8 | ±0.58 | ±0.45 | 19.6 | 10.99 |

| 12 | 19 | 10 | 21.9 | 16.32 | |||

| -14 | 22 | 11 | ±0.70 | ±0.55 | 25.4 | 25.28 | |

| 16 | 24 | 13 | 27.7 | 34.12 | |||

| -18 | 27 | 14 | 31.2 | 44.19 | |||

| 20 | 30 | 16 | 34.6 | 61.91 | |||

| -22 | 32 | -1 | 18 | 36.9 | 75.94 | ||

| 24 | 36 | 19 | ±1.00 | ±0.65 | 41.6 | 111.9 | |

| -27 | 41 | 22 | 47.3 | 168 | |||

| 30 | 46 | 24 | 53.1 | 234.2 | |||

| 36 | 55 | -1.2 | 28 | 63.5 | 370.9 | ||

| 42 | 65 | 32 | ±1.50 | ±0.80 | 75.5 | 598.6 | |

| 48 | 75 | 38 | 86.5 | 957.3 | |||

Note: