How can integrating robots into press brake operations revolutionize your sheet metal manufacturing process? This article explores the essential factors to consider, from operator expertise to programming time and additional investments. By understanding these key elements, you’ll uncover how robotic automation can boost productivity, reduce physical strain, and enhance safety in your workshop. Read on to learn about the benefits and challenges of this advanced technology and how it can transform your production efficiency.

Some experts believe that the use of automated bending units should not lead to job cuts, but rather be seen as an opportunity for experienced bending workers to embrace robots instead of manual processes.

The transition from manual to automated bending operations may be similar to the experience of welding workers in the sheet metal factory, who have gone from resistance to acceptance of automated welding.

There are also experts who argue that bending workers should move away from relying on traditional manual methods and instead incorporate their expertise into bending programs that guide robots or unskilled workers. Only skilled workers who are open-minded and willing to embrace new technologies can ensure the success of an automated bending unit.

However, current software is highly advanced and even first-line workers with limited experience can easily operate state-of-the-art bending units. The days of taking several days to teach a robot to perform simple bending operations on just 5,000 parts are long gone.

The suitability of using robots for bending operations depends on the specifics of the production scenario, but their scope of application is quite broad. Three specific production tasks are ideal for automation:

First, tasks that involve large volumes and repetitive operations can be time-consuming and lead to boredom and physical strain for operators.

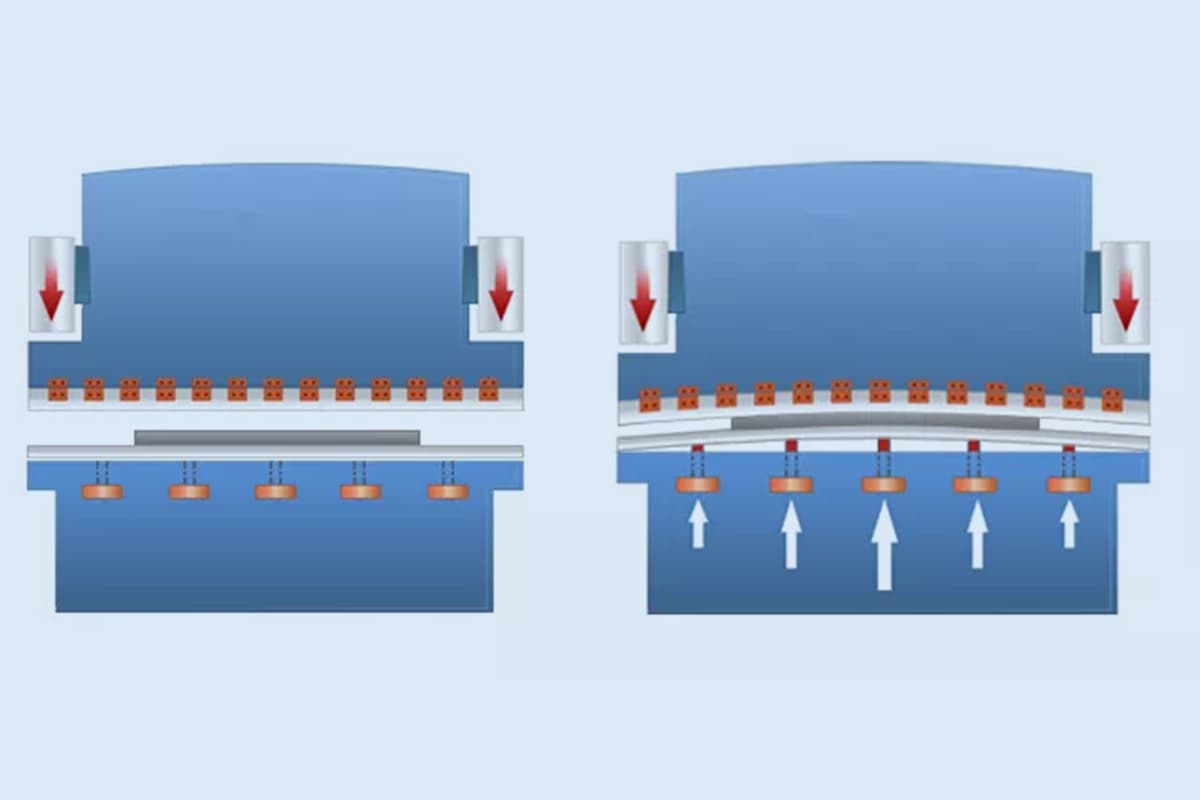

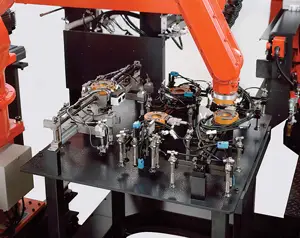

Fig.1

Second, small batch tasks that occur frequently, as depicted in the picture. It’s not only large batch tasks that are suitable for robot bending, small batch recurring tasks are also suitable.

Third, tasks that require two people to lift extra-large parts of material, or that may pose a risk of injury to the operator.

In my view, tasks that do not exceed the robot’s working radius and are within the load range of the press brake are suitable for automation. The key to the automation unit is that one operator can oversee both the manual bender and the automated unit.

It is highly beneficial for a worker to be able to perform bending tasks on both manual and automatic units. Robotic bends may require more setup time than manual bends, but the increase in productivity makes it worth the effort.

In recent years, significant progress has been made in the field of automated bending programming technology. It is no longer necessary for programming the automation unit to require an in-depth understanding of robotics like engineering experts.

With a CAD module, a programmer can submit the data and the software will generate the bend order and operation instructions. While some may still require a real bend test based on the recommendations, software developers argue that these tests may not be necessary.

The software program is now integrated with a 3-D simulation module, allowing for the simulation of robot and press brake movements before the production instructions reach the machine. This simulation also enables detection and visual confirmation of the bend order.

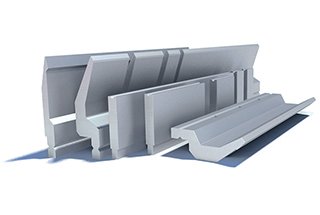

Additionally, the software can generate instructions (as shown in Figure 3) for selecting clamping tools (as shown in Figure 2), robot motion, and material end picker.

Fig.2

Due to advancements such as automatic clamping tool replacement devices, robot bending machines can be quickly adapted to different production tasks.

Fig.3

On a replacement workbench, the robot is able to replace the material end picker in just 25 seconds. In many cases, programming can be done offline to ensure that the automated bending unit remains uninterrupted.

You can’t discuss the topic of robot automation without considering security. The issue at hand is whether a sheet metal factory is willing to invest in a physical fence or a more open and secure grating to ensure the safety of its workers. Two investment options are worth considering.

A safety cover is the most cost-effective option, but it takes up a significant amount of space, which can be problematic for the workshop’s layout. For instance, the bending unit of a leading machine tool manufacturer occupies an area of 12 meters long and 5 meters wide, including a feeder robot, but there is no space for a security fence. In a cramped production workshop, it’s challenging to achieve automated production while also guaranteeing safety.

Workers who are interested in safety gratings should be aware that the Automation unit may cease operation in unexpected situations. The problem with safety gratings is not that they shouldn’t be used, but that many people are unaware of the boundaries and some may accidentally trigger the safety grating’s light by waving their hands through the workshop, thereby shutting down the bending unit.

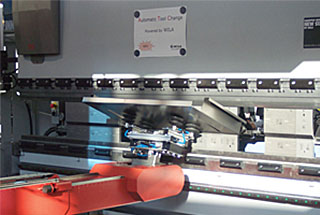

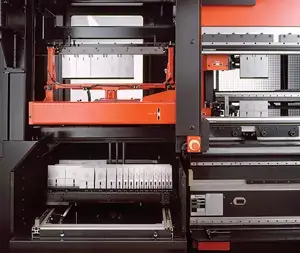

However, safety gratings are ideal for use in relatively open workshops and are more appropriate for companies that strictly limit access to the workshop and clearly mark the boundaries of the production area. Investment in quick-change clamping tools has been previously mentioned, and the next step in this investment should be to add an investment in the newly emerging automated mold library, as shown in Figure 4.

Fig.4

The latest generation of automatic bending units features a programmable mold installation and download system, eliminating the need for manual installation.

Once the program is programmed, the mold library is automatically installed and unloaded by the upper and lower die replacement device, which features a rotating disc that holds the mold and positions it for installation into one of the top and bottom clamping devices.

The primary factor affecting the decision to purchase a press brake is its effective working time. When an operator can handle two bending machines simultaneously, the productivity improvement is evident.

However, investors should focus on equipment utilization. If the automatic press brake frequently shuts down, it will not generate a return on investment, despite the continuous production of parts.

To enhance device utilization, a company should optimize all aspects of the automation unit. In many cases, the preparation time is as long as the production and fabrication time. An automated unit that lacks a quick-change device is ineffective.

How much faster can components be produced on the automation unit with a six-axis back gauge compared to the traditional two-axis back gauge? Improving the efficiency of a single process is meaningless if every process is not smooth.

While considering the length of the production cycle is important, in many cases, shortening the cycle is not as effective as increasing the number of components produced in one shift or day.

The solution to the problem is to reduce the press brake’s standby time, so it can operate for an extended period, significantly increasing production.