How do precise Z-bends and N-bends transform flat sheet metal into complex shapes? This article dives into the essential techniques and precautions for Z and N bending in sheet metal fabrication. You’ll learn about critical procedures, positioning principles, and special processing methods to ensure accurate and efficient results in your metalworking projects. Gain insights into how these bending techniques can enhance your manufacturing processes, improve product quality, and avoid common pitfalls.

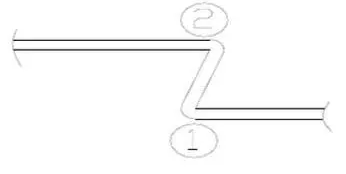

Definition: The bending process in which a material is bent in a zigzag pattern is referred to as Z bending.

Standard bending process range:

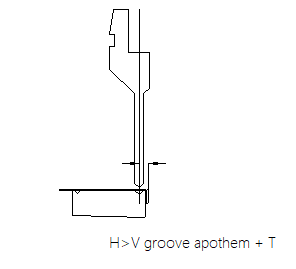

The height of the Z bend must be greater than the sum of the apothem of the V groove and the thickness of the material being bent.

H>T+V/2

The minimum processing size is determined by the model of the machine used, while the maximum processing size is limited by the shape of the machine’s table.

Z Bending Procedures

1) Process the L-bend using the processing method for L-bends.

2) Position the L-bend edge and process it into a Z-bend (or process it into a Z-bend by positioning the other side of the L-bend).

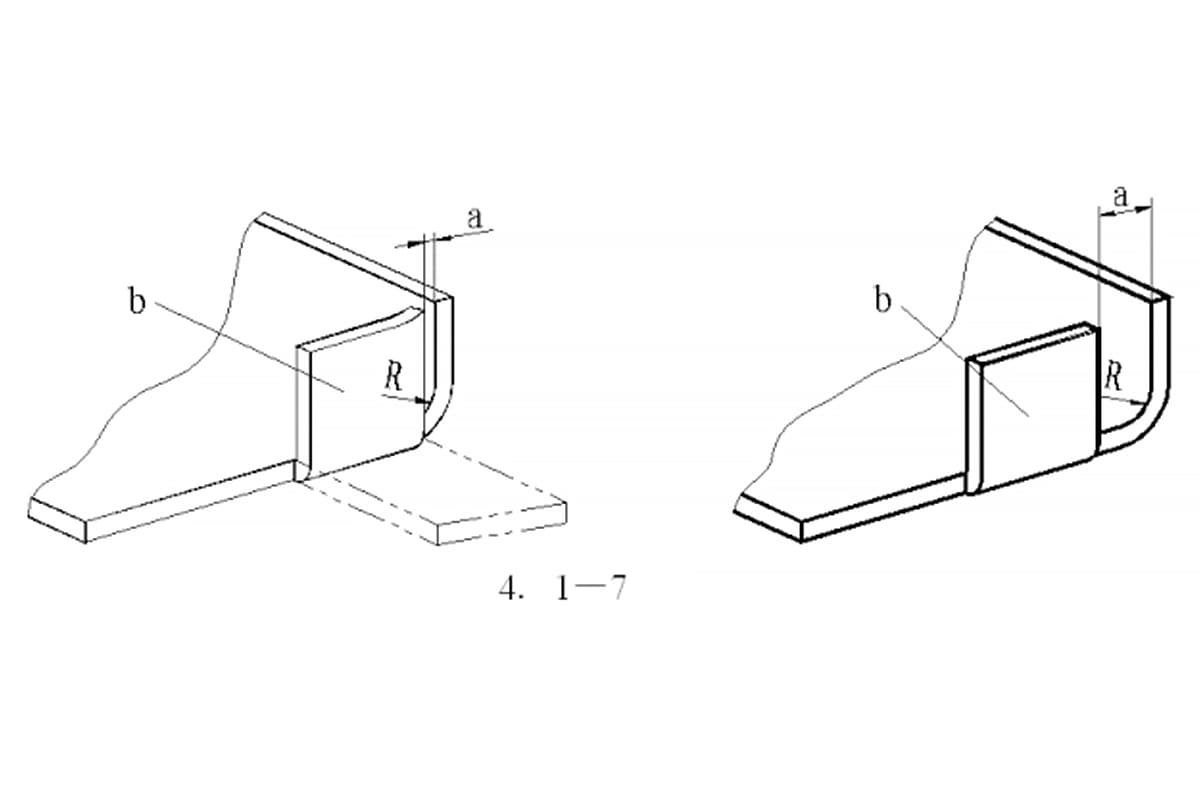

Workpiece Placement Principles for Z-bending

Matters Need Attention for Z-bending

1) The bending angle of the L-bend must be accurate, generally required to be between 89.5 and 90 degrees.

2) The back gauge should be pulled back to prevent the workpiece from deforming during processing.

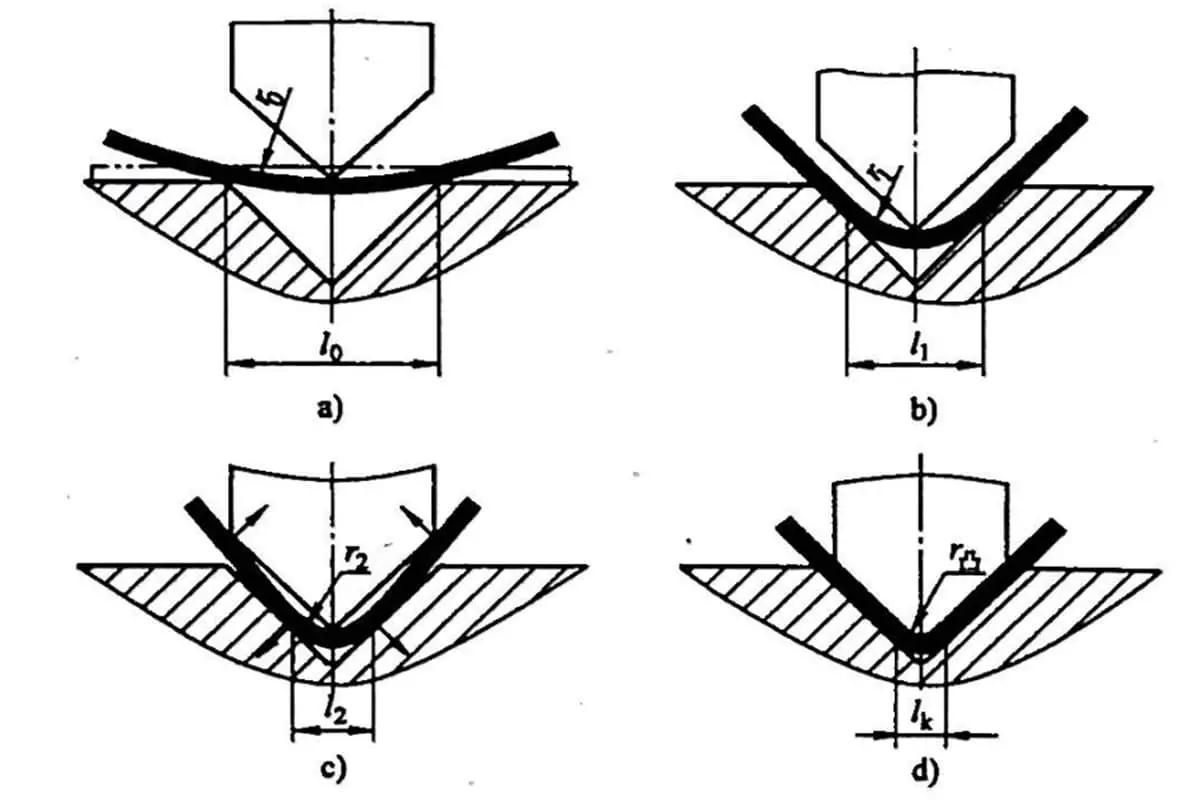

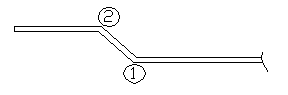

General Processing Methods of Z bending

1) If there is a collision, first bend 1 to form a large angle, then bend 2 and then press 1.

2) if no collision, as per general Z bending processing method, first bend 1 and then bend 2.

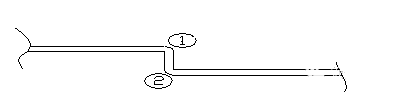

For this type of processing, considering the positioning and interference, bend 2 is first bent to 90 degrees, then inserted to depth 1, and then depth 2 is supplemented.

Special Processing Method of Z bending

1) Centerline separation method (lower die eccentricity) – for sample processing;

2) Forming with a small V-shaped die – for mass production (premise is to add a coefficient);

3) Processing with a ground lower die – applicable in all cases.

1) Processing with offset die – applicable for mass production within the processing range of the step difference die.

2) Forming with a soft die – applicable for mass production.

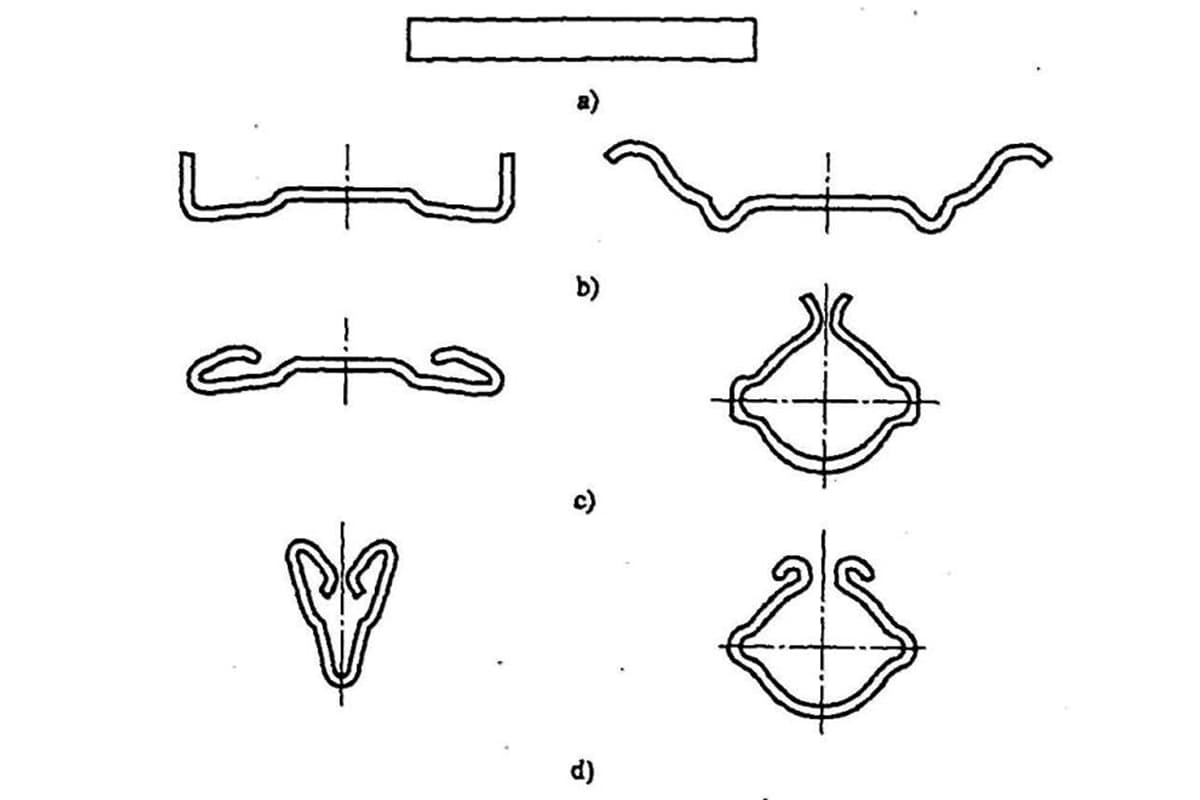

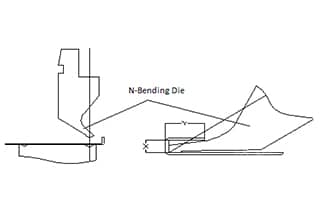

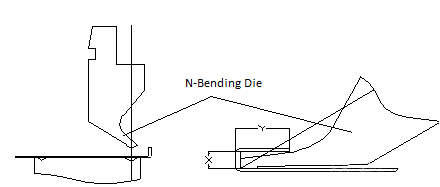

Definition: continuously process the same machining surface twice to form N bending

Precautions for N-bending Processing

The angle of the first bend should be no greater than 90°.

The back gauge for the second bend should be set based on the machined surface.

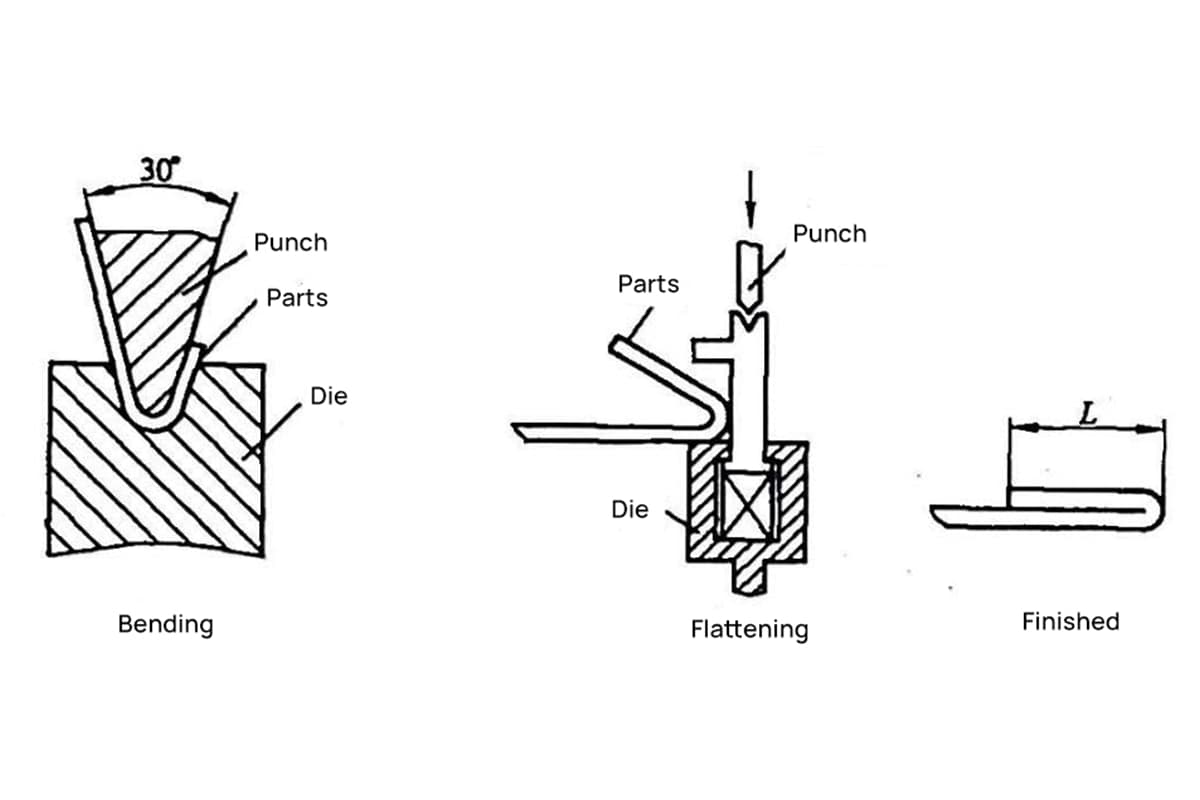

Special Processing Method of N Bending

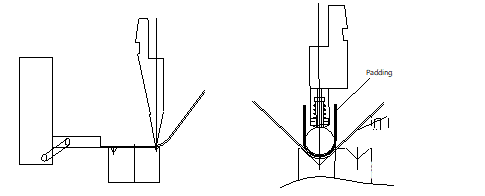

If there is slight interference with the top punch after Y-sized N bending, the material should be flattened using a hemming die after the N bending process.

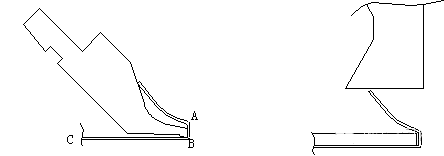

If there is significant interference with the top punch after Y-sized N bending, the material should first be bent to the collision position after the A bend press line, then positioned at point C and bent at point B. Finally, a hemming die and padding should be used to shape the material.

Processing using a shaping punch and die.

Arc Processing

Arc processing can be divided into two categories: circular cutting with a bending model and circular cutting with an arc knife.

Arc knives come in two varieties: fixed and adjustable.

Precautions

A: When machining with a 90° low die, there may be insufficient machining, in which case it is necessary to manually push the mold or, if possible, use an 88° low die.

B: Use a measuring device to verify the dimensional accuracy of the workpiece.

C: When processing a 90° arc, the low die should have a radius of 2 (R + T).