Who would have thought that a single idea proposed by Albert Einstein in 1917 would lead to one of the most revolutionary inventions of the 20th century? This article dives into the intriguing history of the laser, exploring the scientific breakthroughs and key figures behind its development. Readers will uncover the origins of this powerful technology, its impact on various industries, and the ongoing debates about its true inventor. Get ready to learn how the laser, once a theoretical concept, became an indispensable tool in our modern world.

Cutting and joining technology is an important technology cluster in the industrial system.

Laser processing is one of the brightest jewels in this technology cluster.

Especially in today’s Industry 4.0 and smart manufacturing, some people even consider laser processing to be the most natural link with smart manufacturing among all cutting and joining technologies.

So, let’s dig into all that laser industry stuff today and systematically summarize the story of the development of the fiber laser industry.

The history of the industry and technology is an important reference and background that must not be missed by those who later walk alone in the industry and entrepreneurship.

First, let’s review and summarize the basics of lasers.

The laser has been called “the brightest light, the fastest knife, the most accurate ruler”.

It is considered one of the major scientific and technological inventions of the 20th century, the English name “Laser”, namely Light Amplification by Stimulated Emission of Radiation (LASER).

The scientific principle of laser “Stimulated Emission of Radiation” was proposed by Albert Einstein in 1917, “spontaneous and stimulated emission” theory is considered to be the physics of modern laser technology based on.

Einstein pointed out that a particle at a high energy level E2, when the frequency of V = (E2-E1) / h photon incident (h is Planck’s constant), the particle will, with some probability, quickly jump from the energy level E2 to energy level E1, while radiating a foreign photon with the same frequency, phase, polarization state and direction of propagation of photons, this is called excitation radiation.

Do you see what does it mean?

One photon turns out to be exactly the same as the other. What are these two photons going to do next?

That’s right, these two went on to find other particles to fire, making it four.

The process is like a nuclear explosion chain reaction, with the number of photons increasing rapidly, equivalent to the original light signal being amplified.

The laser was not made until 1960, five years after Einstein’s death, when he proposed the theory of “spontaneous and stimulated emission”.

Why did it take so long?

Because of the “stimulated absorption” proposed in Einstein’s paper.

A photon could hit a particle at the E1 energy level, turn it into an E2 energy level, disappear on its own, and the so-called chain reaction would be lost.

For general materials, the stimulated absorbed particles are more than excited particles (more E1 than E2 at lower energy levels), so the intensity of light passing through will not be amplified but reduced.

In order to produce a laser, the key condition is that the “particle number reversal”, high energy particles are more than low energy particles.

But it’s not that hard, looking back to the 1930s, physicists were able to do it.

It’s just that scientists didn’t think to do it because they didn’t have enough integration of optical theory and technology in the 1930s, after all, there were many other significant discoveries.

This makes the invention of the laser a bit of a twist and turn. It was “Maser” (microwave amplifier) that was developed first, and then “Laser” was created.

The photo above is a classic, with Townes on the left, and his student Gordon on the right, in front of a Maser (microwave exciter).

Note that the one in the background on the far right is a Chinese, Wang Tianliang, who later returned to China and founded the Laboratory of Spectroscopy at the Wuhan Institute of Mathematical Physics.

This means that Townes is the originator of the Maser, and is also known to some as the inventor of the laser.

However, scientists also struggle with the position of the inventor of the laser.

Townes, who worked at Bell Labs during World War II, worked on the principles and design of radar.

As a result, Townes became interested in the creation of microwaves and molecular spectroscopy (radar uses microwaves, and now cell phones, wifi, and other wireless communications use microwaves).

After World War II, Townes moved to Columbia University, and it was for building the world’s first microwave exciter (Maser) that Townes won the 1964 Nobel Prize in Physics.

Naturally, Townes wanted to build a short-wavelength microwave exciter (Maser).

If step by step is, millimeter wave, submillimeter-wave, far infrared, mid-infrared, near-infrared, visible light, to ultraviolet light.

Townes has been working in this direction as well.

However, difficulties were encountered with millimeter and submillimeter waves, and it was difficult to succeed anyway, so the plan was to give up for the time being and turn to visible light first, which might be easy and significant.

Together with his brother-in-law, Sholoh, Townes has developed a theory on how to implement this microwave exciter (Maser) in the visible range, which has been very influential.

They shone the light emitted by a neon bulb on a rare-earth crystal, and the crystal would emit a bright, always-collecting light.

In fact, the visible light microwave exciter (Maser), is the Laser.

This set the stage for the invention of the Laser.

At this time, a young man came out from the road, namely Mayman, he was very interested, and also contacted with Townes to create the laser.

Unfortunately, he was not accepted into the revolutionary team. However, Mayman started up his own kitchen and made the laser in 1960.

The picture above shows a ruby laser made by Mayman.

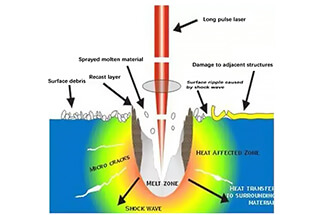

Mayman uses a high-intensity flash tube to excite the ruby. The key here is to have an “optical resonance cavity”, where the light passes through the crystal at a modest magnification, but if a reflector is attached to both ends and the light is constantly magnified back and forth, it’s amazing.

A piece of the reflector, with a little less silver plating on it, leaking out some of the light and out comes the familiar unidirectional excellent laser.

Merman’s one of the fast peach pickers.

Townes and others were certainly very unconvinced and Townes won a Nobel Prize in 1964 and his level was recognized.

Thus, the seeds of controversy were planted as to who was the inventor of the laser.

Just as Edison battled Tesla and Westinghouse over the electric current, the scientific community has no shortage of quarrels and rivalries.

And it is these rivalries that have driven human progress.

In the 1960s, when the world was split into two camps, socialism versus capitalism, the laser community naturally would not be developed without Soviet.

In 1964, for the laser, the two Soviet physicists who won the Nobel Prize at the same time with Townes – Nikolai Basov and Alexander Prokhorov – were awarded the prize.

We all know the story of Soviet leader Khrushchev taking off his shoes and banging on the table at the UNGA meeting in 1960.

We should know: behind the strength and dominance of politicians is a comprehensive national power.

At that time, the Soviet Union was the world’s best not only in nuclear weapons and aerospace but also in basic science, such as lasers.

This was Khrushchev’s confidence.

The Soviet physicist Basov proposed semiconductor lasers that developed the later artifact: the fiber laser.

Basov (right) and Prokhorov (left) lead Townes (middle) to visit their laboratory

Like the team of Townes, Basov and Prokhorov also came up with a “Maser” in 1955 – ammonia molecular beam microwave exciter, and naturally they thought of lasers.

Basov’s contribution is that he published a paper in 1958 and put forward the idea of using semiconductors to make lasers (the theoretical description of “particle number inversion” in semiconductors), and in 1961 he published “carrier injection” PN junctions. Article, and in 1963 created a PN junction semiconductor laser (the Americans first created it according to the principle he proposed).

Semiconductor lasers are not as famous as the ruby lasers that appear in textbooks, but experts are clearly aware of the theoretical significance of semiconductor lasers and the potential is much greater, so the three-way tie for the Nobel Prize went to two Soviet and one American.

The advantages of semiconductor lasers are numerous:

The laser is a rare technology that was immediately practical when it was invented and was used for surgery in 1961.

Because the characteristics of the laser are too outstanding, all the photons of coherence are particularly good, pointing in one direction, the energy applied to a point, can be a million times brighter than the sun.

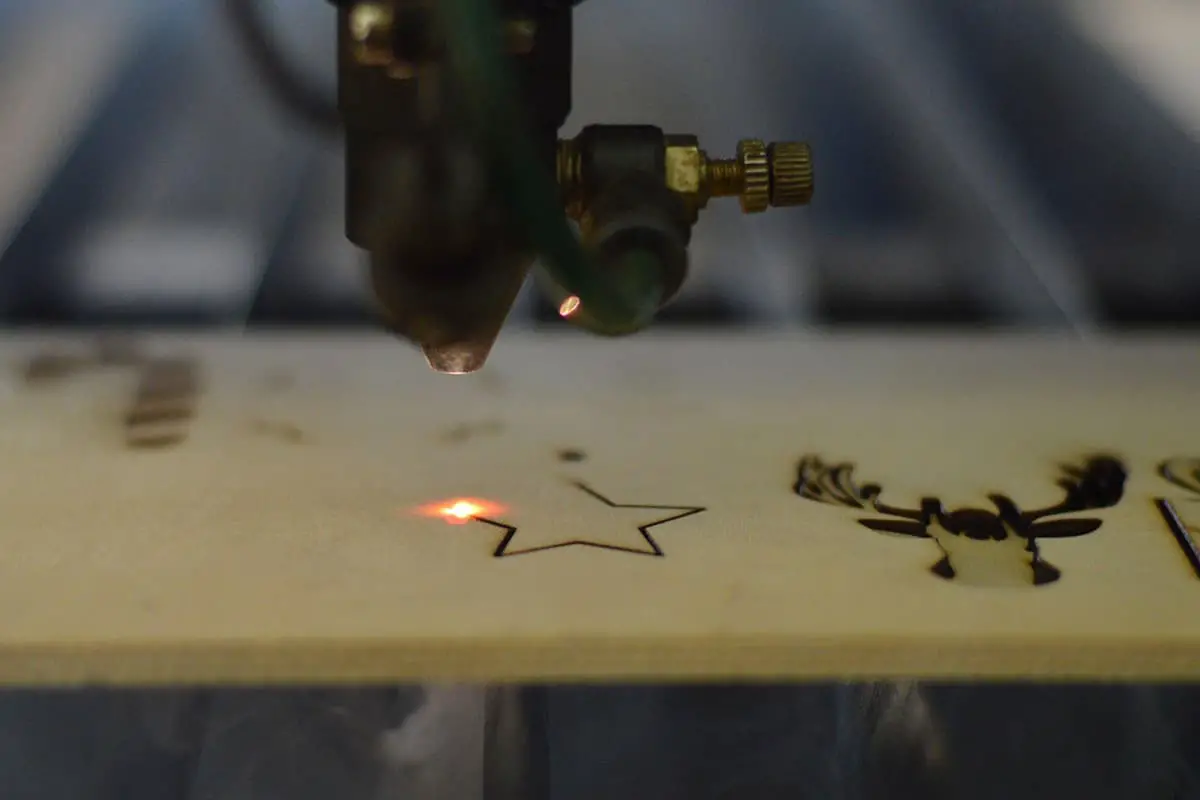

A laser with higher power can be used for cutting and processing.

There are many uses for cutting, welding, measuring, and marking. It is used in countless industries such as communications, industrial processing, medical treatment, and beauty, constantly replacing traditional processes.

At this point, we have to mention China.

This year marks the 40th anniversary of China’s reform and opening up, and 40 years of achievements are not a castle in the air from scratch.

New China laid a complete industrial foundation and investment in basic sciences in the first 30 years, which is the foundation of economic reform and take-off in the past 40 years.

One year after the laser was built in the United States, in the autumn of 1961, Wang Zhijiang, a young researcher from the Changchun Institute of Optics and Mechanics, built China’s first laser in 1961 under the guidance of his teacher, Academician Wang Daheng.

The Father of Chinese Optics-Academician Wang Daheng

The Father of Chinese Lasers – Wang Zhijiang and Ruby Laser

China’s first laser is available, but the name is not yet available.

Just like a young couple who gave birth to their first baby, they always hope to find a respectable elder to give a name.

In October 1964, the editorial department of the magazine “Optical Stimulated Emission Intelligence” (formerly known as “Light Quantum Amplification Special”) sponsored by the Changchun Institute of Optics and Mechanics of the Chinese Academy of Sciences wrote to Qian Xuesen, asking him to give LASER a Chinese name, and Qian Xuesen suggested a Chinese name For “激光”.

In December of the same year, Shanghai held the 3rd Optical Quantum Amplifier Academic Conference, chaired by Yan Jici. After the discussion, Qian Xuesen’s proposal was formally adopted and the English abbreviation LASER of “light amplification by stimulated emission of radiation” was officially translated as “激光”.

Subsequently, the “Optical Stimulated Emission Intelligence” magazine also changed its name to “Laser Intelligence”.

The development of science and technology follows a step-by-step concept from the formulation of basic concepts, to the establishment of basic theories, to the emergence of laboratory products.

In fact, only after it is industrialized can it serve humanity and be able to rejuvenate.

This is the case with laser technology.

In the industrial market, the earliest industrial lasers used for material processing were mainly gas lasers and crystal lasers.

Gas laser, the typical representative is CO2 laser.

The representative of crystal laser is YAG laser, YAG refers to yttrium aluminum garnet with neodymium or ytterbium added.

Today, Rofin Laser’s CO2 slab laser still has a large market share.

The CO2 laser machine uses CO2 as the working material to generate laser radiation, and the auxiliary gases nitrogen and helium are also charged into the discharge tube.

When a high voltage is applied to the electrode, a glow discharge is generated in the discharge tube, causing the gas molecules to release laser light, and the energy is amplified to form a laser beam.

The YAG laser needs to use a krypton or xenon tube as a “pump lamp” to emit light to shine on the Nd:YAG crystal to generate laser light.

The emission spectrum of the pump lamp is a broadband continuous spectrum. Only a few spectral peaks are absorbed by Nd ions, and most of the unabsorbed spectral energy is converted into heat energy, so the energy utilization rate is low.

CO2 and YAG lasers have various shortcomings, but each also has its own advantages.

For example, the high-power laser-produced is still very useful in the industry.

The semiconductor laser has many advantages, but it has a fatal weakness: the quality of the laser light emitted is not good!

The output beam of the crystal laser is of high quality and has high temporal and spatial coherence. It claims to emit a laser beam to the moon with a spot of only 2 kilometers.

The spectral linewidth and beam divergence angle of semiconductor lasers are several orders of magnitude higher than that of crystal lasers.

Therefore, the early semiconductor lasers are generally used as pump light sources. For example, let the semiconductor laser be the pump of the crystal laser and combine the advantages of the two.

The light source emitted by the semiconductor laser, after being “optimized” by the crystal laser, forms a high-quality beam and then emits it.

For example, the disc laser developed by TRUMPF took this path.

TruDisk series disc lasers have the advantages of both solid-state lasers and diode lasers.

Its disc ensures the beam quality of the solid-state laser, and also has the high energy and high efficiency of the diode laser as the pump source.

Speaking of which, I will compare the basic performance of four common industrial lasers (including today’s protagonist-fiber laser).

The comprehensive strength of fiber lasers is truly glamorous and overwhelming.

Table1 Comparison of the basic performance of 4 common industrial lasers

| Item | CO2 Laser | YAG Laser | Disc laser | Fiber Laser |

|---|---|---|---|---|

| Photoelectric conversion efficiency | 10% | 3% | 15% | 30% |

| Maximum output power | 20KW | 6KW | 8KW | 50KW |

| Beam quality BPP (4/5kW) | 6 | 25 | 8 | 2.5 |

| Diode pump life | 5000H | 1000H | 10000H | 100000H |

| Operation and maintenance cost (4/5kW) | 20RMB/H | 35RMB/H | 8RMB/H | 2RMB/H |

There are often examples in the industry.

The old generation of products cultivates the market, the process is switched, and then the new generation of products achieves efficiency improvements.

Fiber lasers appeared in this scenario to improve efficiency.

With the invention of the fiber laser and its launch on the market, some people have doubled their value and become famous.

This is the so-called technical tuyere, and the first person who made this tuyere and seated in this tuyere was the Russian Valentin Gapontsev.

Valentin Gapontsev

Why does Gapenchev make a tuyere and sit on the tuyere?

Gapenchev was born in 1939. He is a senior scientist in the field of laser material physics and the head of the Radio Engineering and Electronic Science Research Laboratory of the Soviet Academy of Sciences. He is of authentic Soviet technical background.

The Soviet Union and the Russians after the disintegration seem to be difficult to run businesses, but Gapenchev will do!

In the 1990s, when the Soviet Union disintegrated, the entire economy began to suffer a devastating blow and even disintegrated. The reason why cowboys are cowboys is that they can always jump out of the pitfalls of history.

Since the goal of fighting for socialism for 50 years has disappeared with the disintegration of the Soviet Union, Nagapenchev will have to face a new historical environment and historical process.

In 1990, he founded IPG Photonics.

In 2006, it was listed on the Nasdaq (IPGP). In 2017, the revenue was 1.4 billion U.S. dollars and the current market value is 6 billion U.S. dollars. It is the most well-known fiber laser company in the industry.

IPG is headquartered in Massachusetts, with manufacturing plants in the United States, Germany, Russia and Italy.

Gapenchev holds nearly half of IPG’s shares and is a billionaire, although he is still the chairman and CEO of the company’s board of directors at the age of 79.

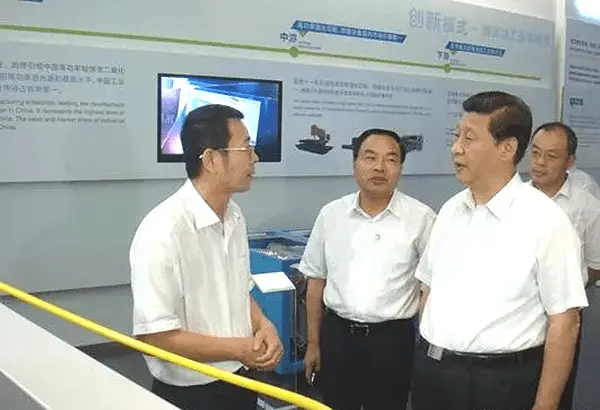

In 2009, Gapenchev accompanied President Medvedev and Minister of Transport Sokolov to visit IPG’s production base in Russia

In 2009, Gapenchev received the Arthur Scholo Award from the American Laser Association, which is the industry’s recognition of his academic achievements.

In 2010, Gapenchev won the Russian National Science and Technology Award, the highest honor for Russian science and technology.

In fact, Gapenchev holds dual citizenship of the United States and Russia.

He can be said to be a genius scientist who cleverly combined the genes of Soviet scientists with the American capital market under the changes of world history.

So, how did Gapenchev make a fortune with fiber lasers in the course of history and still gain the honor?

We have to go back to the crystal laser with the semiconductor laser as the pump light source mentioned earlier.

Generally speaking, bulk crystals absorb high-energy photons with short wavelengths and convert them into low-energy photons with longer wavelengths. Part of the energy is always converted into heat energy in a non-radiative transition.

If this part of the heat energy cannot be dissipated in the massive crystal, it will be fatal and will be burned out in a while, so the heat dissipation problem is very important.

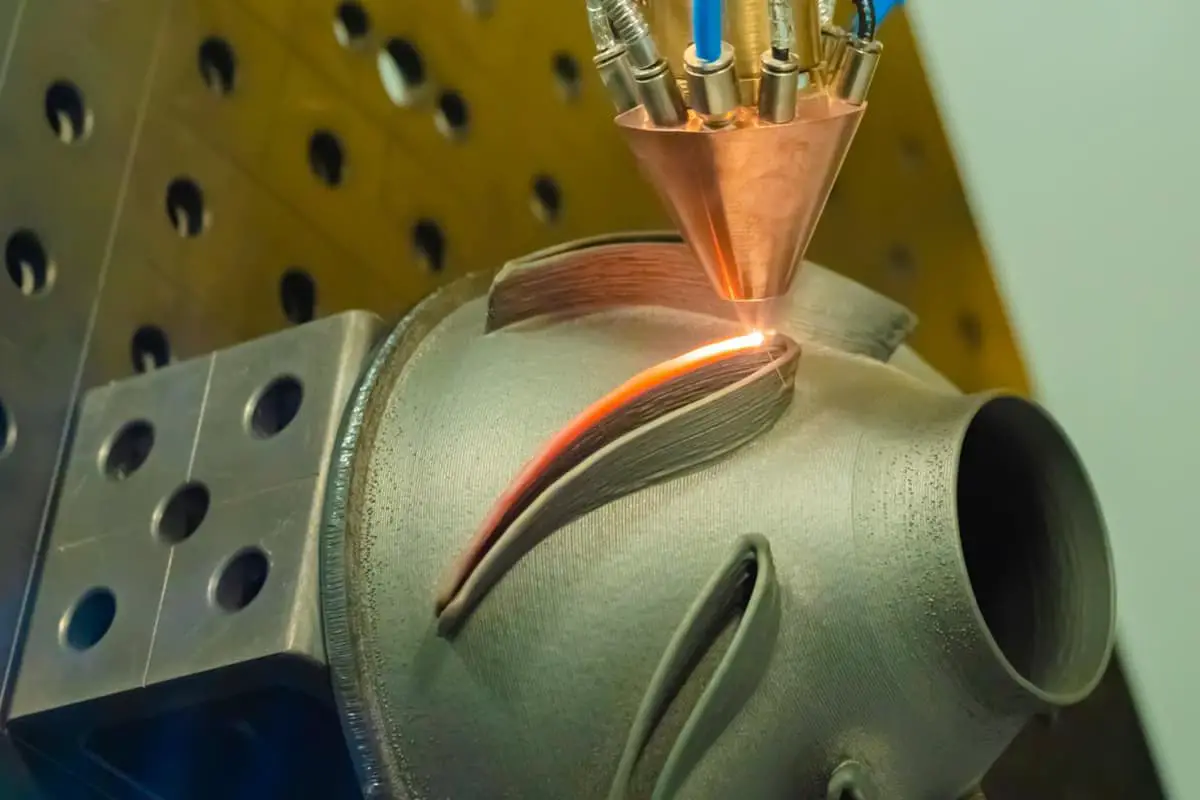

If the bulk crystal can be made into a slender strip, the heat dissipation area will be very large, which can solve the problem. This is actually the appearance of an optical fiber.

Someone made a glass laser in 1964. The crystal used optical fiber, although the light source was not a semiconductor laser.

However, the optical fiber itself was not developed at that time, and the defects were very large, and the light source was difficult to focus on the optical fiber, so there was no progress on this route for more than 20 years.

By the 1980s, semiconductor lasers as pumps had made great progress, and optical fibers had also made great progress with the development of network communications, and the technical conditions of fiber lasers had gradually matured.

In 1987, the University of Southampton in the United Kingdom and Bell Laboratories in the United States proved the feasibility of an erbium-doped fiber amplifier and achieved a key scientific breakthrough.

But the industrial breakthrough was achieved after many years of insistence on IPG founded by Gapenchev in 1990.

Fiber lasers are very high-end high-tech, involving multiple disciplines.

The power of the pumped semiconductor laser must be increased, and the amplification performance of the fiber must be continuously improved.

The trick to improving optical fiber is to add various rare-earth elements to it.

IPG is a typical high-tech enterprise in Western countries, and its research and development is not simple, and its product profit rate is as high as 50-60%.

Fiber lasers have a series of advantages of semiconductor lasers and the advantages of high beam quality of crystal lasers.

From an industrial point of view, the advantages of fiber lasers are clear at a glance compared to CO2 lasers and YAG lasers, and the advantages are so large that there is nothing comparable.

Fiber lasers have absolutely ideal beam quality, as well as ultra-high conversion efficiency of semiconductor lasers, and are completely maintenance-free like optical fibers and LED lights, with high stability and small size. It is really a perfect product.

Of course, new high-tech products have one disadvantage: expensive.

In this world, as long as any product can find a market in China, it will definitely sell well.

No matter how expensive the product is, as long as it can be industrialized in China, the cost can always be kept low.

At this point, we have to mention another Chinese who hold the pulse of the fiber laser industry, he is Gao Yunfeng.

In 1996, Gao Yunfeng founded Han’s Laser.

To enter the market, fiber lasers produced by IPG must be integrated into various laser processing equipment, such as various “laser marking machines” and “laser cutting machines.”

Han’s Laser found a cooperation model with IPG and bought fiber lasers to make processing machines.

Although IPG lasers are expensive, after the system is integrated, the whole machine will dilute the cost and perform well.

Therefore, the application of fiber lasers has prospered in China, and the entire industrial chain is developing in a rolling fashion.

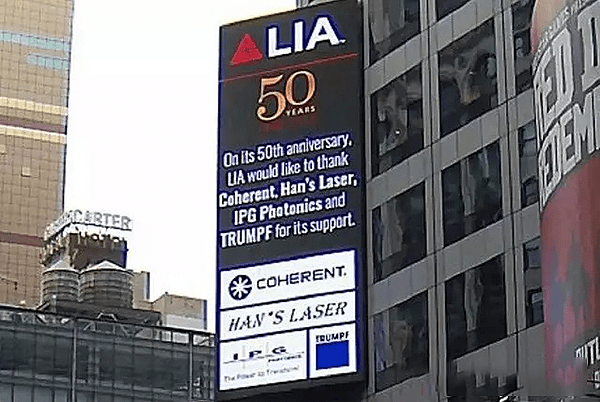

In 2018, IPG and Han’s Laser were elected as the governing units of the Laser Society of America.

The Laser Society of America (LIA) broadcasted on the digital screen of the world-famous Thomson Reuters Building in Times Square, the United States: “On the occasion of its 50th anniversary, LIA would like to thank Coherent, Han’s Laser, IPG Photonics and TRUMPF for their support. .”

Even now, the main market for IPG is still in China.

In 2018, 49% of IPG’s sales depended on the Chinese market.

In 2017, the market value of IPG reached more than 6 billion US dollars, while the market value of Han’s Laser reached 55 billion yuan.

The two are simply a pair of brothers.

Of course, today’s Sino-US trade war has affected the stocks of high-tech companies.

This question belongs to the general environment and is beyond the scope of this article.

If more than 20 years ago, under the background of the disintegration of the Soviet Union, economic globalization and the take-off of Chinese manufacturing, the fiber laser industry made IPG and Han’s Laser.

So now, 20 years later, where is the fiber laser industry?

In China, if it is said that the most disgusting IPG is Wuhan Raycus.

Founded by Dr. Min Dapeng, a doctor who stayed in the US, Raycus has launched its first set of 10W pulsed fiber lasers from 2008 to 20kW fiber lasers in 2018.

From IPG’s point of view, Raycus has madly destroyed the market.

They cut prices and then cut prices, operating within a small profit margin, which undermined market prices.

Every year, Ruike’s price drops by almost 50% or more, which is incredible.

In 2010, IPG can sell a 20-watt fiber laser for more than 150,000. Now Raycus’s offer is 8,800, and IPG can’t compete.

Finally, even the good brother of IPG, Han’s Laser, start to use.

It is said that the trick is very simple. Ask a domestic manufacturer to ask for a few fiber lasers to use, let them open the interface definition, find some people to copy the success, and then stopped buying.

Therefore, in IPG’s view, the Chinese have actually destroyed the market.

Of course, if the buttocks are in different positions, they will say different things.

Back then, the development of cutting-edge laser technology was one-third of the world in China.

From China’s point of view, Chinese companies can indeed drastically reduce costs under the premise of ensuring a certain profit, without killing the market. The actual effect is to promote the application quickly.

In fact, the popularity of industrial lasers depends on China’s fierce cost reduction and application promotion.

Countries such as India and Vietnam with a certain scale of manufacturing application demand also use low-cost industrial laser equipment made in China, and they are quite recognized for Raycus products.

Samsung’s factory in Vietnam uses a lot of Chinese company’s machines.

Moreover, the reason why Chinese companies can madly reduce costs is that the large-scale industrial chain is complete.

For example, optical lenses cost 10,000 in Germany and 1,000 in China.

Parts such as cylinder guides are domestically produced, and there are few core parts without localization.

With the advancement of localization, the cost has dropped rapidly. In 2015, a 3-watt ultraviolet laser sold for 90,000, and now 20,000.

Moreover, China’s large number of R&D personnel has turned industry competition into a competition to quickly meet customer needs.

When Han’s Laser competed with South Korean EO in Vietnam, products with the same configuration were more than 100,000 cheaper, because the parts of IPG were cheap, and a large number of young engineers were sent to Samsung’s Vietnam factory for day and night debugging.

There are few Korean engineers sent by EO and their hair is gray.

The automatic laser equipment of the American company takes half a year, and the Chinese company directly quotes 30%, and the construction period is one month.

And in the United States, old engineers who are about to retire do it. No one will do it after retiring.

Throughout the history of laser development, the semiconductor laser technology handed down from the former Soviet Union has developed into a fiber laser because of China’s huge demand and cost reduction promotion.

At present, Raycus is not the only China’s fiber laser manufacturer, but the market seems to have formed a red sea.

No one knows what this market will become in the future.

When analyzing a thing, we sometimes need to jump out of the existing silos. For example, due to the development of semiconductor laser coupling technology in recent years, high-power semiconductor lasers have gradually begun large-scale industrial processing applications.

See also: