Why can’t China produce panel benders like Salvagnini’s? Despite mastering low- and mid-range machine tools, China faces economic challenges with high-end machines. High R&D costs, lengthy development cycles, and limited market demand make such investments unprofitable. This article explores these economic barriers and market dynamics, shedding light on why China prioritizes more cost-effective, semi-automatic solutions over expensive, fully automatic machines.

The machine tool is not actually complicated.

China has already mastered the technology for low- and mid-range machine tools.

The challenge with high-end machines is not the difficulty of the technology, but rather its unprofitability.

This situation is similar to the situation with the metal ball in a ballpoint pen in the past.

The market for high-end machine tools is limited and the development cycle can be very lengthy.

If it involves starting from scratch rather than a model upgrade, the R&D for a medium to high-end machine tool can easily cost several hundred million RMB.

The R&D cycle is several years long and the returns are relatively limited.

Due to the low market demand and fragmentation, the payback period may be more than ten years.

The return on investment for high-end machine tools is even worse.

For most mass-produced industrial production, high-end machines are not actually necessary.

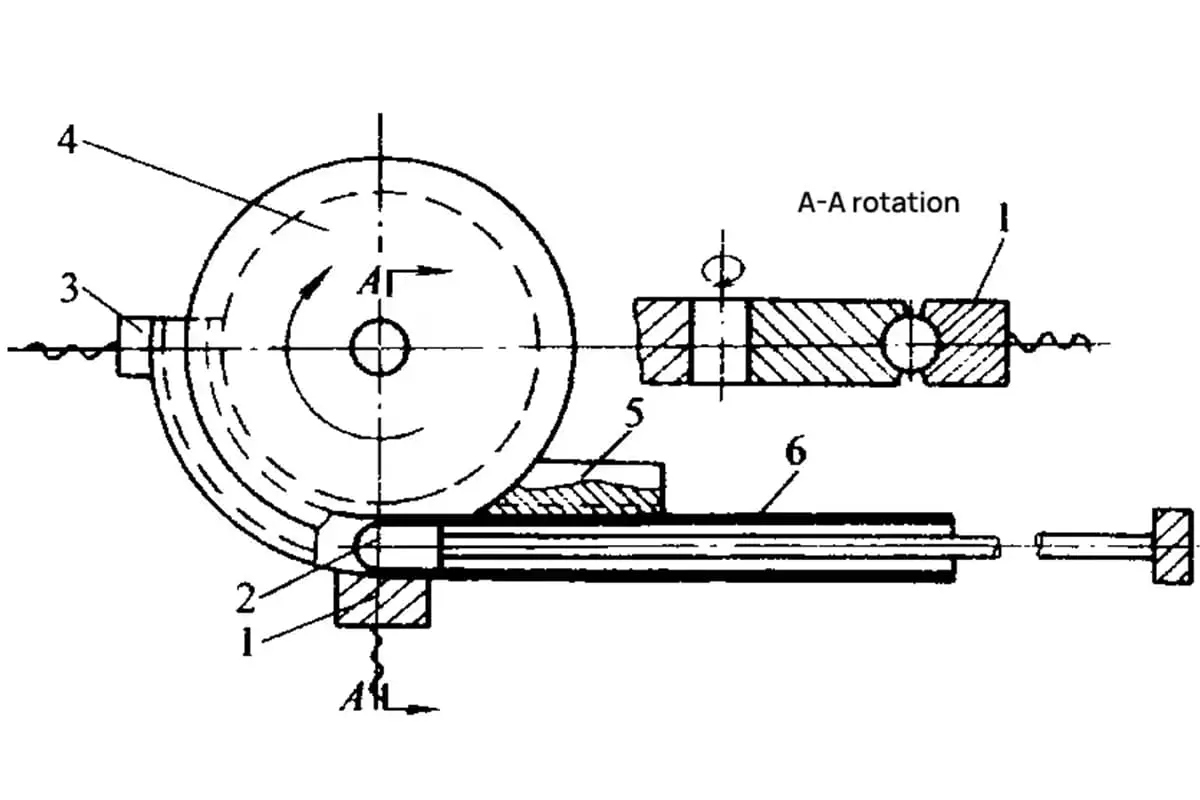

First, let’s take a look at the following video of a panel bender:

This machine is a fully automatic panel bender from the Italian manufacturer Savanini, which sells for one million euros.

Is it good? Yes, it’s very good. Bending workers will be impressed by it and sheet metal engineers will be moved by it.

However, is it necessary for mass production? It is hardly necessary.

In fact, today’s mass production prefers semi-automatic machines and highly customized manual/semi-automatic equipment because of the high degree of control over processes, sequences, and deployment locations, as well as their lower cost.

A well-deployed production line consisting of semi-automatic machines can achieve higher productivity than these fully automatic high-end machines at a comparable cost.

Even if full automation is required, the current trend is to have fully automated production lines consisting of industrial robots along with program-controlled semi-automatic customized machines/equipment.

These high-end machines are usually used to produce small quantities of products, such as custom products, prototypes, process tests, and so on.

Not only are they expensive to purchase, but they are also expensive to use and maintain and require specific education for the operators.

Therefore, their application areas will be very limited at least in the next decade or two.

In this case, investing heavily in the R&D of high-end machine tools is not necessarily a very cost-effective behavior.

Preventing China from excelling in high-end machine tools is primarily due to the limited market size and returns.

There are still many people who believe that high-end machine tools are some kind of advanced technology that China cannot overcome.

Some even use the Soviet Union’s purchase of Japanese machine tools as evidence of China’s inability to make them.

However, the Soviet Union has been gone for almost 30 years now.

This mentality is prevalent in many traditional industries and it is underestimating today’s China to claim that it cannot develop a technology that was developed by foreigners 30 or 40 years ago, even after investing enough money.

It is not that China cannot make a panel bender like the one produced by Savagnini, but rather that it is not willing to do so.