In the rapidly evolving world of manufacturing, laser welding has emerged as a game-changer. But what exactly sets this technology apart from traditional welding methods? Join us as we delve into the intricacies of laser welding, exploring its advantages, limitations, and the ways it’s revolutionizing industries from automotive to aerospace. Discover how this precise and efficient process is shaping the future of fabrication.

Laser welding is a modern fabrication process that uses laser technology in order to achieve precise and efficient welds. It involves a highly concentrated beam of light which acts as a heat source. The laser beam delivers a controlled amount of energy to a specific location, creating a strong bond between materials. This advanced non-contact process offers various benefits and drawbacks.

One of the main advantages of laser welding is its ability to perform high-quality welds with minimal heat input. The laser beam is focused on a small area, leading to reduced thermal distortion and maintaining the integrity of the materials. This precision results in improved weld quality, minimal post-processing requirements, and reduced production time.

Laser welding technology also provides increased control over the heat source. Due to the concentrated light, the heat input can be precisely adjusted based on the desired depth and width of the weld. This characteristic enables both deep penetration welds as well as thin-sheet welding without significant damage to the material. The non-contact nature of laser welding further reduces the risk of contamination and allows for more sanitary welds in industries such as medical device manufacturing and food processing.

However, there are some cons associated with laser welding. One major limitation is the requirement for compatible materials. Not all metals and alloys can be welded effectively using lasers. Reflection and absorption of the laser-beam can be factors that determine the weldability of the material, and some materials may require specific laser types or additional processing techniques to facilitate proper welding.

Another drawback of laser welding is the initial investment cost. The equipment and maintenance for laser technology can be expensive, particularly for high-power laser systems. Additionally, skilled operators familiar with laser welding procedures are necessary, which can further increase costs.

Even with its limitations, laser welding is a reliable and efficient technique, suitable for various industries. It provides a clear advantage over other traditional welding methods in terms of precision, control, and quality, but comes with a higher initial cost and material compatibility challenges. Overall, the decision to implement laser welding should be based on individual project requirements and production capabilities.

TIG (Tungsten Inert Gas) welding is a traditional welding method that uses a non-consumable electrode made of tungsten. This method provides a high level of precision and control. In contrast, laser welding offers several advantages, such as faster processing times, less heat distortion, and the ability to weld dissimilar metals. However, TIG welding is better suited for certain materials, such as aluminum and magnesium, which require more control due to their sensitivity to heat.

MIG (Metal Inert Gas) welding is another traditional method that uses a consumable electrode made of metal wire. This method is commonly used for steel and aluminum materials. Laser welding outperforms MIG welding in terms of speed, precision, and the ability to weld complex geometries. On the other hand, MIG welding provides better penetration in thicker materials and requires less extensive surface preparation compared to laser welding.

Spot welding is a traditional process that uses electrical current to join two pieces of metal by applying pressure at specific points. Laser welding has some distinct benefits compared to spot welding, including the ability to weld a wider range of materials and achieve a stronger bond. Additionally, laser welding reduces the risk of mechanical damage and produces less heat, making it suitable for temperature-sensitive materials. However, spot welding is a more cost-effective solution for high-volume production and simpler joints.

Resistance spot welding is a variation of spot welding, which uses electrical resistance between two electrodes to generate heat and melt the metals being joined. While resistance spot welding has good repeatability and is widely used in the automotive industry, laser welding offers better precision, reduced distortion, and improved aesthetics. Furthermore, the non-contact nature of laser welding eliminates the need for consumable electrodes, reducing maintenance and operational costs. Despite these advantages, resistance spot welding remains more accessible and cost-effective for certain applications.

Compared with other welding technologies, laser welding has several advantages:

However, laser welding also has some limitations:

Laser welding has become a popular choice in the manufacturing industry due to its ability to offer precise and consistent results with minimal damage to materials. This technology can be easily integrated into various manufacturing processes, allowing engineers to streamline production and reduce costs. Some common applications in manufacturing include automotive components, electronics, and medical devices. The efficiency and flexibility of the laser system make it a valuable tool for manufacturers.

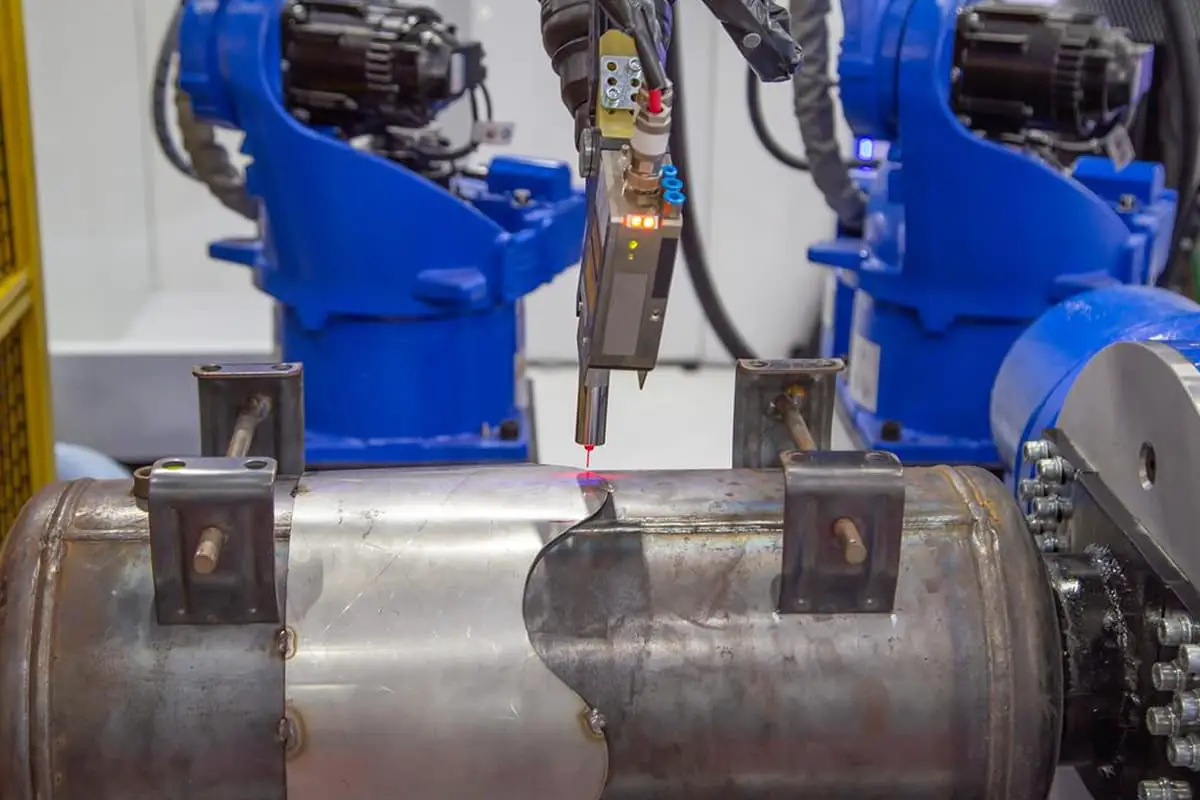

In the realm of automation, laser welding plays a significant role in enhancing productivity and reducing human intervention. With the help of robots and advanced laser systems, tasks such as welding, cutting, and sealing can be performed with high precision and accuracy. In the automotive industry, for instance, laser welding is used to produce lightweight vehicle structures through advanced metal joining techniques. As a result, automatic production lines benefit from reduced downtime and increased quality control.

The aerospace industry demands high-quality, strong, and lightweight materials for their components, making laser welding an ideal solution. Aerospace engineers utilize laser welding to create critical components such as aircraft engines and control systems where precision is of utmost importance. Moreover, laser welding provides reduced heat input, minimizing material distortion and ensuring the structural integrity of the final product. With these advantages, the aerospace industry can rely on this technology to meet their rigorous production standards.

Laser beam welding has established its place among modern welding processes due to its numerous advantages. It offers precision, reduced thermal impact, and ease of use, making it suitable for various industries. The technology allows for efficient joining of materials, resulting in high-quality welds.

However, the high initial cost of laser beam welding equipment may be a deterrent to some businesses looking to invest in this technology. A proper analysis of ROI is necessary before making the decision to implement laser welding. While the upfront costs may appear overwhelming, the long-term benefits could potentially offset these costs.

In summary, laser welding is a viable solution for many applications, particularly those requiring precision and minimal thermal impact. Advancements in technology continue to improve its ease of use, making it an attractive option for industries seeking to optimize their welding processes. Nevertheless, businesses should carefully weigh the initial costs against the potential benefits before incorporating laser welding into their operations.