What if adjusting the focus of your laser cutter could mean the difference between a clean cut and a failed project? In laser cutting, the focal point’s position is crucial for precision and quality. This article explains how to choose the correct focus, detailing positive, negative, and zero-focus techniques, and offers tips on machine inspection to ensure optimal performance. Discover how to achieve the best cuts for different materials and applications.

Before cutting any sheet, the distance between the laser focal point and the material to be cut must be properly adjusted.

Different focal point positions can result in varying levels of precision in the cross-section of the cut material, as well as differences in bottom slagging and even failure to cut the material.

The choice of focal point position for the laser cutting machine will depend on the workpiece and the material to be cut.

To make the right choice, it is important to inspect the laser cutting machine prior to use to ensure high-quality cuts and proper machine operation.

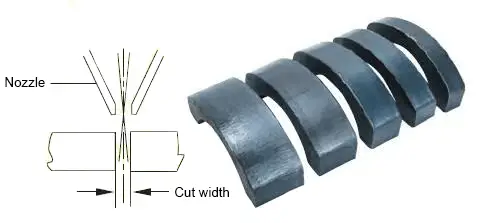

Positive focus cutting refers to positioning the focal point above the material being cut, with the focal point located on top of the workpiece.

For carbon steel oxygen cutting, a positive focus is preferred.

The cutting width at the bottom of the workpiece is greater than that at the top, which helps in removing slag and allows oxygen to reach the bottom of the workpiece to facilitate full oxidation.

Within a certain focal range, a larger positive focal point leads to a larger spot size on the surface of the plate, which results in better preheating and heat supplementation around the cut, and results in a smoother and brighter cutting surface of carbon steel.

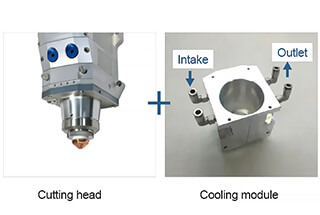

For 10,000-watt laser pulse cutting of thick stainless steel plates, positive focus cutting provides a stable quality, which is beneficial for slag removal and reduces the risk of reverse blue light, as shown in Figure 1.

Fig. 1 The effect of a 12000W laser cutting carbon steel with a positive focal point

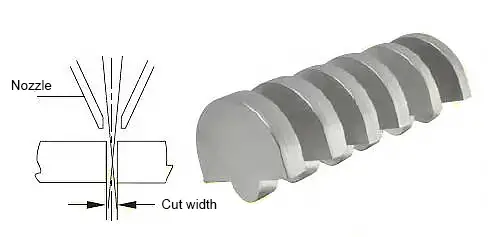

Negative focus cutting refers to positioning the focal point within the workpiece.

In this mode, the focal point is farther from the cutting surface, resulting in a relatively larger cutting width within the workpiece compared to positive focus cutting. However, a larger cutting airflow and sufficient temperature are required.

Negative focus cutting is suitable for cutting stainless steel, resulting in a uniform cutting surface pattern and a good cross-section.

When perforating the plate prior to cutting, a negative focus is preferred to ensure a minimum perforation spot size and maximum energy density.

The deeper the perforation position, the larger the negative focus point, as shown in Figure 2.

Fig. 2 The effect of a 6000W laser with a negative focus on stainless steel

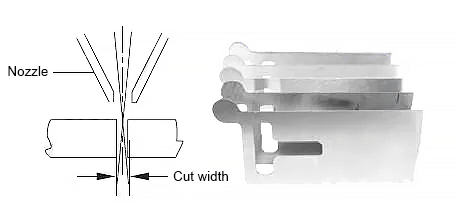

Zero-focus cutting refers to positioning the focal point on the surface of the workpiece. In this case, the cutting surface near the focal point is relatively smooth, while the lower surface away from the focal point appears rough.

Zero-focus cutting is mainly used when cutting thin sheets with continuous lasers and when cutting foil layers with pulsed lasers through peak power vaporization.

Fig. 3 2000W laser cutting of thin carbon steel sheets at zero focus

The lens of the 10,000-watt cutting head is crucial to the 10,000-watt laser cutting machine. Its cleanliness directly impacts the machine’s processing performance and cutting quality.

If the lens is dirty, it can not only negatively impact the cutting results but also cause damage to the internal components of the cutting head and the laser output head.

Performing a pre-check before cutting can prevent serious damage.

The red light detection method is shown in Table 1.

Table 1 Red light detection method

| Nozzle | Single nozzle above 2mm | Clean lens | Dirty lens |

| Methods | 1. Red light is indicated when the laser is turned on; |  |  |

| 2. The white paper is about 300mm away from the cutting head nozzle to view the red light; | |||

| 3. If there are black spots or irregular black objects in the red light, the lens is dirty and needs to be cleaned before cutting and debugging. |

2) Coaxial debugging.

The co-axiality of the nozzle outlet hole and the laser beam is a crucial factor that impacts the cutting quality. Inconsistencies caused by misalignment of the nozzle and the laser beam can result in an irregular cutting surface. In severe cases, the laser beam may hit the nozzle, leading to overheating and burning of the nozzle.

The coaxial debugging method is shown in Table 2.

Table 2 Coaxial debugging method

| Nozzle | Nozzle 1.2mm | Normal coaxial | Abnormal coaxial |

| Tools | Sticky tapes | Three coaxial  |  |

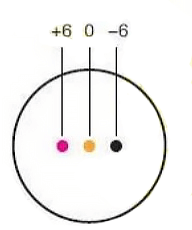

| Methods | 1. Coaxial adjustment at focal point 0, so that the laser is in the center of the nozzle; | ||

| 2. Light at focal point ±6mm; | |||

| 3. If focus 0 and ±6mm hitting light point are in the center of the nozzle, it is normal. If not, it needs to replace the cutting head or laser light path offset. |

The shape of the laser spot directly reflects the distribution of laser energy in the lateral direction. The roundness of the spot indicates the uniformity of energy distribution in different directions.

A highly rounded spot with uniform energy distribution in all directions can guarantee a smooth cutting surface and consistent cutting speed in all directions, ensuring the quality of the cutting products.

Table 3 is the spot distribution check method.

Table 3 Coaxial debugging method

| Nozzle | Single nozzle above 2mm | Normal laser spot | Abnormal laser spot |

| Tools | Black laser spot paper |

|

|

| Methods | 1. The black laser spot paper is about 300mm away from the cutting head nozzle to make a spot; | ||

| 2. If there are black spots in the spot, the lens is dirty; | |||

| 3. If the spot is not round and the center is shifted, then the laser spot is poorly distributed |

One of the major issues with using 10,000 watt lasers for cutting thick carbon steel plates is the overheating of the nozzle. To address this, it is important to test the nozzle temperature for various nozzle sizes and focal points at full power output before beginning the cutting process.

Before conducting the tests, it is necessary to align the co-axiality so that the light spot is centered at the nozzle outlet. Additionally, a cooling gas system for cutting should be installed for the nozzle.

Test method:

Iron buckets filled with a suitable amount of water should be placed beneath the cutting head.

The auxiliary gas (the type of gas and air pressure should be adjusted based on the specific requirements for cutting) should be blown first, and the laser should be operated at full power for 30 seconds to monitor any changes in the nozzle temperature.

The nozzle size should then be changed and the testing process repeated.

The heat generation of different nozzles should be recorded and used as a reference for the subsequent cutting process setup.

If the nozzle temperature does not remain within a narrow range, it may indicate a problem with the cutting head, nozzle, lens, or laser, and further troubleshooting should be performed before proceeding with the next step in the cutting process setup.

The choice between using a positive or negative focal point for laser cutting does not depend on the metal material being cut (such as stainless steel or carbon steel), but rather on the cutting method being used (such as oxidation cutting or fusion cutting).

Different workpieces processed by the laser cutting machine may require different focal patterns.

DBy considering the different effects of positive and negative focus on cutting stainless steel and carbon steel, and taking into account their individual processing needs, users can select the appropriate focus cutting method to fully utilize the performance benefits of the laser cutting machine.

When it comes to 15kW lasers from different brands, they generally have similar cutting results and processing efficiency for both carbon steel and stainless steel.