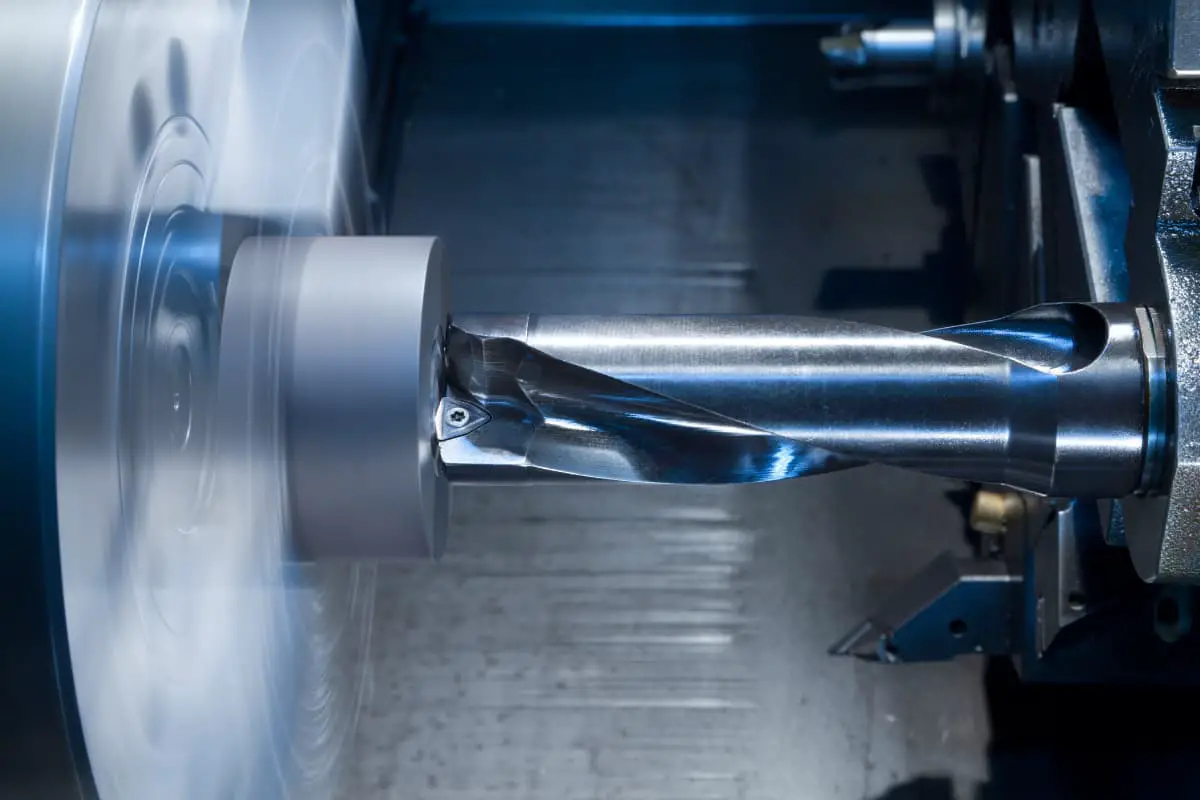

The working environment of the CNC cutting machine is relatively harsh, with significant metal dust.

Therefore, the machine must be thoroughly cleaned and maintained, with designated personnel responsible for equipment lubrication, repair, and maintenance.

1. Assemble the torch correctly:

2. Replace consumables in time:

3. Clean the torch’s connection threads:

4. Clean the contact surface of the electrode and nozzle:

5. Daily check of gas and cooling air:

6. Avoid torch collision damage:

7. Most common causes of torch damage:

8. Precautions:

1. Ensure the Correct Pressure and Flow of Plasma

The correct pressure and flow of plasma are critical to the lifespan of consumables. If the pressure is too high, the life of the electrode will be significantly reduced; if the pressure is too low, the life of the nozzle will be affected.

2. Use a Reasonable Cutting Distance

Adhere to the instructions in the manual and use a reasonable cutting distance — the distance between the cutting nozzle and the surface of the workpiece. When piercing, try to use twice the normal cut distance or the maximum height that can be transmitted by the plasma arc.

3. The Piercing Thickness Should be Within the Allowable Range of the Machine System

The cutting machine cannot pierce steel plates that exceed the working thickness. The typical piercing thickness is half of the normal cutting thickness.

4. Don’t Overload The Nozzle

Overloading the nozzle (i.e., exceeding the working current of the nozzle) will damage the nozzle quickly. The current intensity should be set at 95% of the nozzle’s working current. For example, the current intensity for a 100A nozzle should be set at 95A.

5. Maintain Dry and Clean Plasma Gas

The plasma system requires dry and clean plasma gas to function correctly. Dirty gas, often a result of issues with the gas compression system, will shorten the life of consumables and cause abnormal damage. Test the quality of the gas by setting the torch in test mode and placing a mirror under it. If moisture or fog appears on the mirror, identify the cause and correct it.

6. Start Cutting from the Edge

Start cutting from the edge whenever possible instead of piercing. Using the edge as a starting point will extend the life of consumables. The correct method is to aim the nozzle directly at the edge of the workpiece and then start the plasma arc.

7. Avoid Prolonged Extension of the Plasma Arc

If the plasma arc can only reach the surface of the workpiece by extending, this extension will occur at the start and end of the cut, causing abnormal damage to the nozzle. By using the correct edge-starting technique and selecting the appropriate “arc-off” signal time, this issue can be avoided.

8. Reduce Unnecessary Arc-Starting Time

The nozzle and electrode wear out quickly during arc-starting. Before starting, place the torch within the travel distance of the cutting metal.

9. Apply Anti-Spatter Chemical Coating on the Protective Shell

Anti-spatter chemical coatings help reduce slag accumulation on the protective shell. However, only apply the coating after removing the protective shell from the torch.

10. Remove Slag from the Protective Shell

Regularly remove slag from the torch’s protective shell; otherwise, the slag will cause destructive double plasma arcs.

11. Purge Gas After Replacing Consumables

After replacing consumables or after a long shutdown, purge the gas (for 2-3 minutes) to ensure water and mist are expelled from the torch.

12. Keep the Torch and Consumables Clean

Any dirt on the torch and consumables will significantly impact the functionality of the plasma system. Place consumables on a clean cloth when replacing them, regularly check the torch’s connection threads, and clean the electrode contact surface and nozzle with peroxide-based cleaners.

13. Remove Oxides from Air or Oxygen Nozzles

When using air or oxygen plasma, oxides will accumulate inside the nozzle, affecting the gas flow and reducing the life of consumables. Wipe the inside of the nozzle with a clean cloth to remove oxides.

14. Use Softened Water in the Torch

Hard water can deposit metal impurities on the nozzle ring, affecting the gas flow, reducing the quality of the torch, and shortening the life of consumables.

15. Check Air Flow and Cooling Flow Daily

One of the most common causes of torch damage is insufficient cooling flow. Regularly check the airflow and pressure to the torch (if air-cooled) or the coolant (if water-cooled). If the airflow is insufficient or if there’s a leak, stop the machine immediately and fix the issue.

As the founder of MachineMFG, I have dedicated over a decade of my career to the metalworking industry. My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for metals. I am constantly thinking, reading, and writing about these subjects, constantly striving to stay at the forefront of my field. Let my knowledge and expertise be an asset to your business.