Imagine a world where precise, high-speed cutting of diverse materials is seamlessly integrated into various industries. This is the power of CO2 laser technology. From metal processing to medical applications, CO2 lasers offer unmatched efficiency and versatility. In this article, discover the cutting-edge advancements and future directions of CO2 lasers, and learn how they continue to revolutionize sectors like manufacturing, healthcare, and materials processing. Prepare to explore the transformative potential of CO2 lasers and their enduring impact on modern technology.

The Carbon Dioxide (CO2) laser was invented by C. Kumar N. Patel in 1964 at Bell Laboratories. It is also referred to as a glass laser tube and is a laser product with a high continuous output power, widely used in the textile, medical, materials processing, and industrial manufacturing industries. It has unique applications in the fields of packaging coding, cutting non-metallic materials, and medical aesthetics.

CO2 laser technology advanced in the 1980s and has been widely utilized in industrial processing for over two decades. It is used for cutting metals, marking and engraving various materials, welding, and cladding processing in industries such as automotive, shipbuilding, and aerospace.

The industrial CO2 laser operates at a wavelength of 10.64μm and produces infrared light. Its electro-optical conversion efficiency is generally between 15% to 25%, which is a significant advantage over solid-state YAG lasers.

Due to its wavelength range, the CO2 laser beam can be effectively absorbed by a variety of materials including steel metals, non-ferrous metals, precious metals, and non-metals.

Related reading: Ferrous vs Non-ferrous Metals

Its range of applicable materials is even wider than that of fiber lasers.

Despite fiber lasers having set off a boom in metal material processing since 2010, particularly in the replacement of some CO2 cutting market, the most significant application of current laser processing is still metal material processing.

However, this has led to some misconceptions, with some people mistakenly believing that CO2 lasers are now outdated and have limited usefulness.

This notion is entirely incorrect.

CO2 lasers are the most technically mature, stable, and reliable type of light source and have a long history of process development. They continue to be widely used in Europe and the United States for various applications.

Many natural and synthetic materials have strong absorption characteristics in the 9-12 μm spectral range, which is the range covered by CO2 lasers. This makes them ideal for materials processing and spectral analysis.

The beam properties of CO2 lasers also make them ideal for unique applications, as they provide unique potential.

In this article, we will focus on several common applications of CO2 lasers.

Before the rise of continuous fiber lasers, high-power CO2 lasers dominated the metal plate processing industry. I recall a manufacturer showcasing a 4KW CO2 cutting machine at an exhibition in 2012, which was capable of cutting plates thicker than 20mm and made a huge impact on the industry at the time.

Today, fiber lasers with a power of 10,000+ watts are used to cut ultra-thick plates. Although CO2 cutting has been mostly replaced by fiber cutting in steel cutting, it has not completely disappeared.

Fiber lasers are easier to cut because of their finer spot, but this becomes a disadvantage in welding. When it comes to thick plate joining, high-power CO2 lasers have an advantage over fiber lasers.

Although beam oscillation was introduced a few years ago to address the limitations of fiber lasers, it still cannot match the performance of CO2 laser beams.

In addition to welding steel materials, recently, materials such as chromium-manganese alloy steel and aluminum alloys that are challenging to weld have started to emerge. Some of these materials have high melting points and high reflectivity of light, which requires high laser power for welding.

CO2 lasers are mainly used for surface treatment through laser cladding. Although it can also be done with semiconductor lasers, before the advent of high-power semiconductor lasers, laser cladding was largely the domain of CO2 lasers.

Laser cladding is widely used in various industrial fields, such as molds, hardware, mining machinery, mechanical spindles, aerospace, offshore equipment, and even new civilian products.

CO2 lasers have a significant cost advantage over semiconductor lasers, making CO2 laser cladding a popular option.

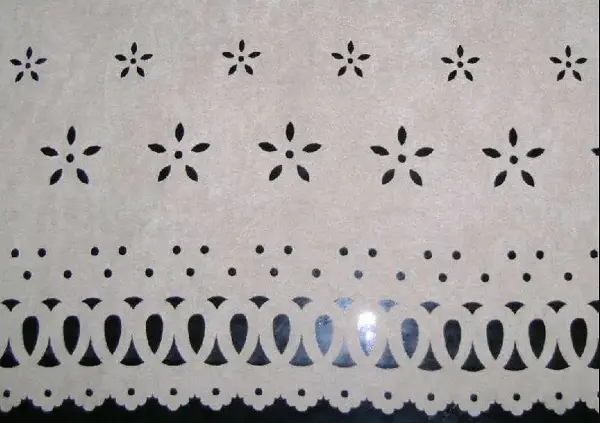

In metal processing, CO2 lasers face competition from fiber lasers and semiconductor lasers. As a result, the future application of CO2 lasers is likely to focus on non-metal materials, including glass, ceramics, fabric and leather, wood, plastic, and polymers.

The nature of the CO2 laser beam offers great potential for customized special applications, such as processing of polymers, plastics, ceramics, etc. CO2 lasers can achieve high-speed cutting of polymer materials such as ABS, PMMA, PP, and so on.

By using advanced CO2 lasers with optimized optical patterns and optical path designs, it is possible to form a more perfect spot, reducing the heat-affected area and cutting high-quality cell phone film products such as PET protective film and display panels.

The unique advantages of CO2 laser cutting technology make it more suitable for precision film cutting than UV laser cutting technology and better meet the needs of precision processing in the IT industry.

In the 1990s, high-energy pulsed medical devices, such as ultra-pulsed CO2 laser therapy machines, emerged and were successfully applied in demanding applications, particularly in the field of laser aesthetics. This development has a very promising future.

CO2 laser-assisted deep sclerectomy, or CLASS for short, is a non-penetrating and non-subconjunctival follicle-dependent procedure that reduces intraocular pressure through the trabecular meshwork, deep sclera, and choroidal drainage of aqueous fluid.

This innovative procedure has few intraoperative and postoperative complications, is non-filtration follicle-dependent, and does not result in postoperative scarring. It is simple, has a short learning curve, is easy to master, and is highly effective in clinical practice.