Sheet metal shears, as the name implies, is a machine used for cutting sheet metal. The material selection is based on the general Q235 plate. If cutting Q345 plate, then the model should be chosen 1.4 times larger. If cutting stainless steel, the model should be chosen 1.6-2 times larger. If cutting 10-40mm plate, a […]

Sheet metal shears, as the name implies, is a machine used for cutting sheet metal.

The material selection is based on the general Q235 plate.

If cutting Q345 plate, then the model should be chosen 1.4 times larger. If cutting stainless steel, the model should be chosen 1.6-2 times larger. If cutting 10-40mm plate, a guillotine shear is a better choice.

Check out How to distinguish the steel plate from Q235 and Q345.

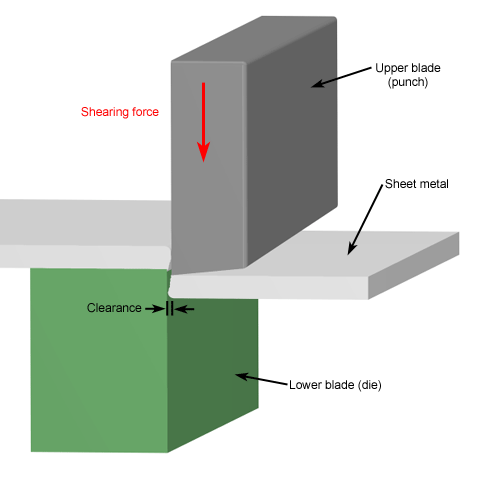

Metal shears are widely used in the sheet metal fabrication industry and can cut a variety of thicknesses of steel plate material. The machine used is called a squaring shear, power shear, or guillotine. It can be powered by foot, hand (less commonly), or mechanisms such as mechanics or hydraulics. The material is first clamped with a ram, and then a moving blade comes down across a fixed blade to shear the material.

Metal shears classification:

Generally, plate cutting machines can be divided into several types: foot-powered shears, mechanical shears, hydraulic swing beam shears, hydraulic guillotine shears, and hydraulic CNC-controlled shears.

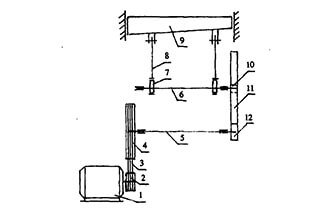

Hydraulic shears work by moving the upper blade and the fixed blade with a reasonable blade gap to apply a shearing force to metal plates of various thicknesses, resulting in the plate being cut to the required size.

Sheet metal shears are often used to cut straight-edged blanks. The shearing process should ensure that the shearing surface is linear and parallel to the required specifications, and minimize sheet distortion to produce high-quality workpieces.

Metal cutting shears are a type of forging machinery, mainly used in the metal processing industry. These products are widely used in industries such as light industry, aviation, shipbuilding, metallurgy, instrumentation, electrical appliances, stainless steel products, steel construction, and decoration.

According to the Machinery Industry Standard of the People’s Republic of China, a plate shear is defined as:

A machine that uses a blade that moves in a straight line against another blade to cut a sheet.

Often, metal shears are used in conjunction with other equipment to fulfill specific purposes:

Thick plate lines mostly use hydraulic high-speed plate cutting machines, while thin plate lines are usually equipped with pneumatic metal cutting machines. High-speed lines use flying shear machines, which are known for their continuous production and high efficiency.

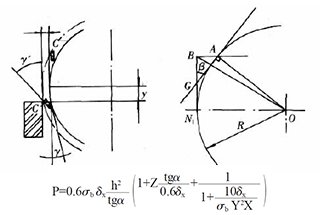

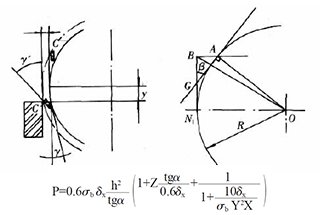

The upper and lower blades of the metal shearing machine are angled, with the upper blade typically inclined at an angle of 1° to 6°.

The cutting force of an inclined blade shear is smaller than that of a flat blade shear, which leads to a reduction in motor power and the overall weight of the machine.

Shearing quality is good with minimal twisting deformation, but it requires a large shearing force and energy consumption. Most machines use mechanical transmission.

The cutting edges of the cutting machine are parallel to each other and are commonly used in rolling mills for hot billet and slab shearing. They can be divided into upper cutting and lower cutting methods.

Joint punching and shearing machine (ironworker machine): This machine is used to complete the shearing of plates, as well as cutting profiles, and is mainly used for the blanking process.

Sheet bending cutting machine: This machine can complete both the shearing and bending processes on the same machine.