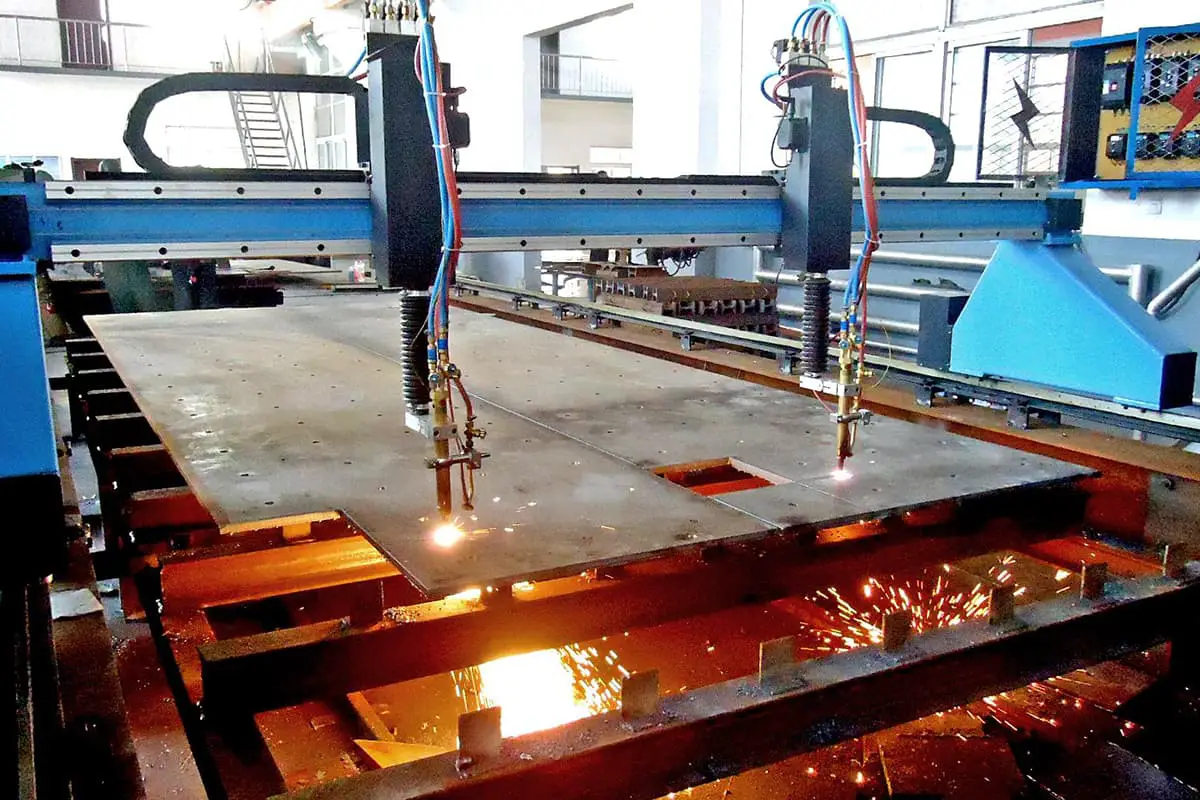

Plasma cutting is a cutting technology that uses a high-temperature plasma arc with high energy density to heat the material at the cutting point and rapidly fuse it. This cutting method is considered ideal for medium to thin plates due to its high cutting efficiency and good quality, which is why it is widely popular […]

Plasma cutting is a cutting technology that uses a high-temperature plasma arc with high energy density to heat the material at the cutting point and rapidly fuse it.

This cutting method is considered ideal for medium to thin plates due to its high cutting efficiency and good quality, which is why it is widely popular among users.

Since the 1990s, plasma technology has continuously improved, leading to a longer service life for its consumables such as electrodes, nozzles, and vortex rings. This has greatly reduced the cost of plasma consumables and expanded the potential for plasma cutting applications.

According to an investigation conducted at the steel processing workshop of Dalian Shipyard, a comparison was made between plasma cutting machines and traditional oxyacetylene cutting methods.

The main cost of plasma cutting is related to the consumables such as electrodes, nozzles, and vortex rings, while the primary cost of oxyacetylene cutting is attributed to oxygen and acetylene. The costs for both cutting methods are calculated as follows:

| Gas | M3 / bottle | Yuan/bottle | Yuan / m3 |

| oxygen | 4 | 19 | 4.75 |

| acetylene | 5 | 70 | 14 |

| Plate thickness (mm) | Cutting speed (mm / min) | Oxygen flow (m3h) | Acetylene flow (m2 / h) |

| 18 | 520 | 3.65 | 0.73 |

Oxygen consumption for cutting one meter steel plate:

3.65÷60÷0.52=0.12 (m3)

0.12yuanx4.75=0.57yuan

Consumption cost of acetylene for cutting one meter steel plate:

0.73÷60÷0.52=0.024 (m3)

14 yuan x0 024 = 0.34 yuan

Total cost of cutting one meter of steel plate:

0.57 yuan + 0.34 yuan = 0.91 yuan

Take the MAX200 of Hypertherm company as an example:

| Project | Continuous cutting service life | Unit Price | Calculated service life | Yuan/hour |

| Electrode | 46 hours | 50 yuan | 4 hours | 12.5 |

| Injector | 4-6 hours | 128 yuan | 4 hours | 32 |

| Vortex ring | 15-25 hours | 181 yuan | 10 hours | 18.1 |

| Electric current | Power | Efficiency | Plate thickness | Electricity price |

| 200A | 30 KW | 100% | 18mm | 0.80 yuan / degree |

Hourly electricity charge for cutting steel plate:

30kW x 100% x 0.8yuan= 24yuan

Cost of consumables per hour:

(12.5 yuan + 32 yuan + 18.10 yuan) = 62.6 yuan

Cost per minute for cutting steel plate:

(12 yuan + 62.6 yuan) ÷ 60 = 1.24 yuan

The total cost of cutting one meter of steel plate:

1.24 yuan ÷ 1.5 = 0.826 yuan

The theoretical calculation shows that the cost per meter of oxyacetylene cutting is higher than that of plasma cutting. However, the investigation conducted at the shipyard reveals that in practical application, the cost of both methods is roughly the same, with plasma cutting having a slight advantage.

When cutting an 18mm steel plate with plasma, the speed is 1500mm/min, while the speed of oxyacetylene cutting is 500mm/min. This means that plasma cutting is three times faster than flame cutting, resulting in a much higher production efficiency.

When comparing the cutting quality, plasma cutting shows its advantages. The workpiece cut by plasma has no burrs or slag, and the surface is smooth and free of edge collapse. The cutting accuracy tolerance per meter length is no greater than 0.5mm, and the workpiece has minimal deformation. This means that plasma cutting can often replace or eliminate the need for machining.

Practice has proven that plasma cut parts do not require machining and fully meet the quality requirements for welding assembly.

The plasma cutting process eliminates the need for machining, which means that machining equipment can be saved and the cost of machining, which can be hundreds of thousands of yuan each year, can be reduced.

In addition, plasma cutting is highly efficient, meaning that one plasma cutting machine can replace 2 to 3 oxyacetylene cutting machines. This significantly reduces the production area and improves the effective utilization efficiency of the plant.

The overall benefits of plasma cutting are substantial.

The cost of operating a plasma cutting machine is comparable to that of an oxyacetylene cutting machine. However, due to its high efficiency, high quality, and substantial economic benefits, investing in a plasma cutting machine is still the best choice despite the initial large investment.

It is recommended that factory leaders create the necessary conditions to purchase a CNC plasma cutting machine. The manufacturer can also choose to include both a flame and a plasma cutting gun in their configuration to prepare for future production increases.