Ever wondered how to ensure the molds you use in manufacturing are top-notch? This article dives into the ten key factors that influence mold quality, from selecting the right steel to proper maintenance. By understanding these essential elements, you’ll be equipped to improve efficiency, reduce costs, and extend the lifespan of your molds. Discover practical tips and expert advice that will elevate your mold quality to the next level. Read on to uncover the secrets of high-quality molds.

Steel is a crucial component of mold quality, so choosing the right steel is of utmost importance.

When selecting steel, the following standards should be considered:

① Requirements for Injection Molding Materials:

Different plastics require different types of steel, depending on factors such as high polishing requirements, corrosion resistance, etc.

② Price:

It is important to choose steel that meets the requirements, rather than simply selecting the most expensive option. To avoid unnecessary waste, the mold steel should be selected based on the expected die life and overall cost of the mold.

③ Heat Treatment:

Surface treatment of the mold is also crucial.

Nitriding can increase the surface hardness of steel and prolong the die life.

Electroplating can improve the performance of steel by modifying it and enhancing its brightness and corrosion resistance, especially for plastic materials that require these properties.

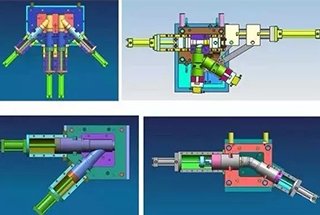

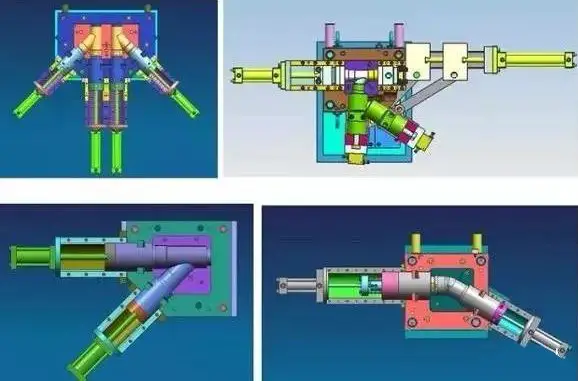

A well-designed mold structure not only considers the material properties of the product, such as shrinkage, forming temperature, and elastic tensile deformation coefficient, but also factors in the speed of cooling water and the speed of opening and closing modes.

By having a reasonable mold structure, the die life can be effectively prolonged and production can run smoothly. This leads to improved efficiency and reduced costs.

“A good tool makes a good handyman.”

It is crucial to have a well-planned molding process. A reasonable process arrangement can shorten production cycles, reduce processing time, and effectively save costs.

Moreover, precise and reasonable processing is essential to ensure the stability and longevity of the mold during production.

Processing errors can lead to mold burnout or welding, causing a loss to the mold, even if the welding is of high quality. Additionally, such errors can impact the movement of the mold, shorten its lifespan, and even cause it to break down during production.

The capacity of a bucket is determined by its weakest point.

While this may seem obvious, it is often overlooked during the process.

The same is true for molds. Standard parts, which are not directly involved in shaping but control the entire mold operation, play a critical role.

High-quality standard parts should be wear-resistant, hard enough, highly precise, and resistant to deformation.

Different brands offer a wide range of standard parts, so it’s important not to simply choose the cheapest option. Doing so can seriously impact the quality of the mold.

Die arrangement requires the expertise of a skilled tool fitter and is considered the most technical aspect of the process, despite its seemingly simple nature.

The complexity of a mold heavily relies on these skills.

Flat dies are the simplest, as long as there are no sharp edges on the fractal surface.

However, arranging auto parts dies can be more challenging as they often have more irregular fractal surfaces and multiple sliders and top blocks.

Through proper mold arrangement, other issues can also be addressed, making it a comprehensive task.

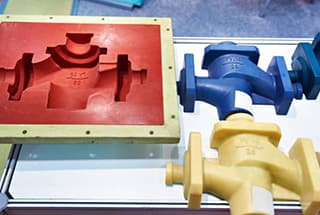

The polishing of the mold is the final step in the mold-making process.

Polishing has a direct impact on the appearance of the plastic parts, making it the most visually important aspect of the work.

In addition, polishing can improve the operation of the mold, particularly during the demolding process.

Sometimes, die production can be hindered by inadequate polishing, resulting in increased resistance and difficulty during demolding, as well as stress marks and cracks on the top end.

Assembling a die is similar to assembling a machine, where every part and every screw must be in place. Any mistake can result in serious consequences, ranging from defective products and disrupted production to completely damaged molds and scrap.

Therefore, the assembly process must be approached with great care and attention to detail.

Particular emphasis should be placed on cleaning the mold during assembly, especially the water paths and screw holes, which must be thoroughly cleaned of iron filings to avoid customer dissatisfaction.

The impact on mold quality is actually minimal, as the hot runner is typically specified by customers, particularly for large ones.

The quality and after-sales service of foreign famous brands are exceptional, so quality is usually not an issue.

However, the quality of some hot runners in China can vary greatly.

Small businesses often compromise on quality to save costs and use unreliable heating and transmission components, which can lead to problems.

The main challenge with the cold runner is ensuring a balanced injection molding process, with consistent size of the injection nozzle, injection pressure, etc.

Anyone with experience in molding knows the significance of cooling in the molding process.

With the rise in material and labor costs, manufacturers aim to reduce the injection cycle for mass production, which results in increased mold temperature. If not effectively controlled, this can result in poor mold formation or even mold deformation, leading to scrapping.

Therefore, an efficient waterway design is crucial, including the distribution density, diameter, and connections among the waterways.

Mold maintenance refers primarily to maintenance activities during the production process.

Just like a car, if a mold is not used for an extended period of time and not properly maintained, it may become unusable.

Therefore, it is important to thoroughly maintain the mold each time it is used, paying close attention to the rust on the forming parts and applying anti-rust protection to the main moving parts.

Due to the mold’s exposure to water during production, water droplets may accumulate on the mold during installation or disassembly. To prevent this, ensure that the mold is completely dry before brushing a layer of oil to protect it.