Why choose one welding method over another? This article dives into the key differences between laser welding and resistance welding, explaining their principles, advantages, and applications. Discover how laser welding offers precision and speed with minimal heat distortion, while resistance welding excels in simplicity and cost-effectiveness for joining metals. By understanding these differences, you’ll be able to select the most suitable welding technique for your specific needs, enhancing both efficiency and quality in your projects.

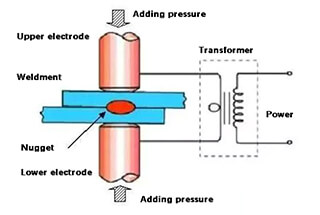

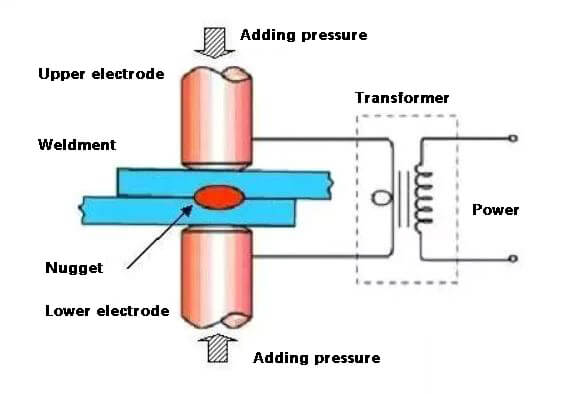

Resistance welding is a manufacturing process and technology used for joining metals or other thermoplastic materials, such as plastics, by heating. This method of welding involves applying pressure through the electrode after the workpiece is combined, and utilizing the resistance heat generated by the current passing through the contact surface and adjacent area of the joint.

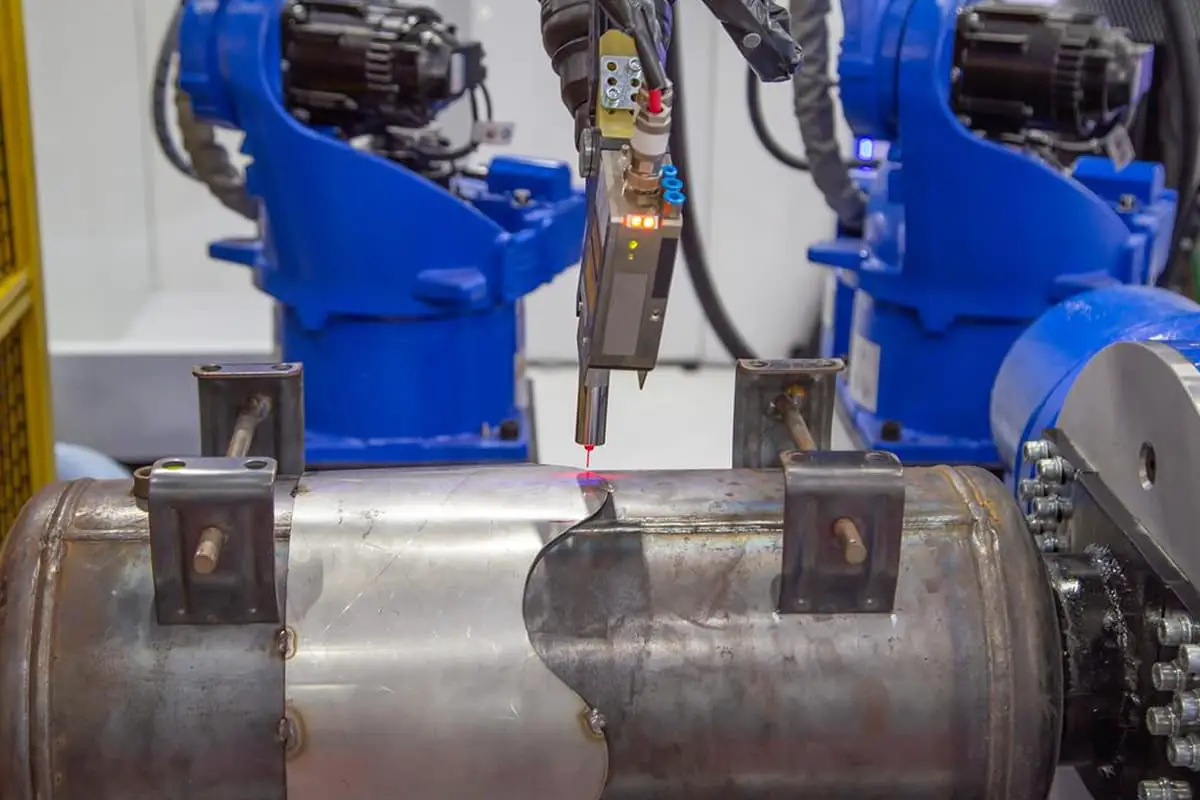

Laser welding is a high-efficiency, precise, non-contact, pollution-free, and radiation-free welding method that uses a high-energy density laser beam as the heat source.

According to the welding process, it is divided into:

Spot welding machine, projection welding machine, seam welding machine and butt welding machine.

According to the energy supply mode, it is divided into:

Single-phase power frequency welder, secondary rectifier welder, three-phase low-frequency welder, energy storage welder and inverter welder.

According to the welding method, it is divided into:

Spot welding, continuous welding, butt welding, overlap welding

According to the light output mode, it can be divided into:

Pure fiber laser welding, hard optical path fiber transmission laser welding, YAG laser welding, and semiconductor laser welding.

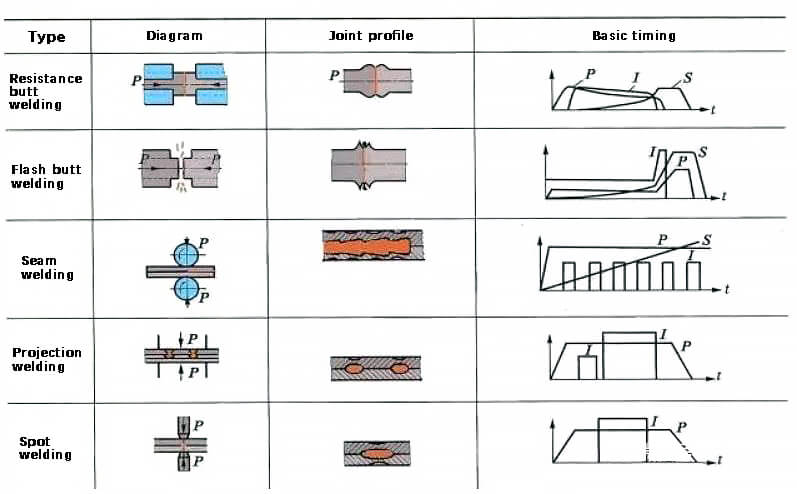

Resistance welding methods mainly include spot welding, seam welding, projection welding and butt welding (resistance butt welding and flash butt welding)

Spot welding is a type of resistance welding in which two metal pieces are joined by heating them at the point of contact. The metal is melted and welded together by resistance heating caused by pressing the pieces between two cylindrical electrodes in a lap joint configuration.

Spot welding is mainly used for sheet welding.

Process of spot welding

① Prepress to ensure good contact with the workpiece.

② Power on to form nugget and plastic ring at the welding joint.

③ Power off forging to make the nugget cool and crystallize under the continuous action of pressure to form a solder joint with dense structure and no shrinkage cavity and crack.

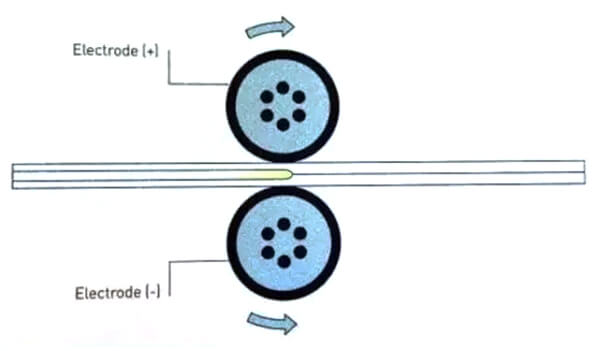

Seam welding is similar to spot welding in its process, but instead of using cylindrical electrodes, it utilizes a rotating disc-shaped roller electrode. The metal pieces to be welded are positioned in a lap or butt joint and placed between the two roller electrodes. The roller applies pressure and rotates, continuously or intermittently applying power to create a continuous weld.

Seam welding is commonly used for welding structures that require regular welds and seals, and is typically used on metal plates that are less than 3mm in thickness.

Projection welding is a type of spot welding that involves the use of pre-formed bumps on the workpiece. During the projection welding process, one or more nuggets can be formed at the joint simultaneously.

Resistance butt welding is a process that joins metal pieces in a butt joint configuration by bringing their end faces into close contact, heating them to a plastic state through resistance heating, and then quickly applying pressure after turning off the power to complete the welding.

This method is primarily used for welding metal pieces with simple shapes, with a diameter or side length less than 20mm, and low strength requirements.

Flash butt welding is a process that joins metal pieces in a butt joint configuration by gradually bringing the end faces into close contact, heating these points of contact through resistance heating, creating a flash under the influence of high current, melting the metal at the end, and then quickly applying pressure after turning off the power when the metal reaches the desired temperature within a certain depth range.

The joint quality of flash welding is superior to that of resistance welding, and the mechanical properties of the welded joint are equivalent to those of the base metal. There is no need to clean the surface of the joint before welding.

Flash butt welding is frequently used for welding crucial metal pieces and can be used to weld both the same metal or different metals, as well as metals ranging from 0.01mm metal wire to 20000mm metal bars and profiles.

Currently, there is a shortage of reliable non-destructive testing methods to assess welding quality, and it can only be evaluated through destructive tests of process samples and workpieces, as well as various monitoring technologies.

The lap joint used in spot and seam welding not only adds weight to the component, but also creates an angle around the weld nugget of the two plates, leading to a low tensile strength and poor fatigue strength of the joint.

The equipment used in welding has high power and high levels of automation, making it expensive and difficult to maintain. The commonly used high-power single-phase AC welding machines can also disrupt the balance of the power grid.

Laser welding minimizes heat input and reduces the size of the metallurgical change in the heat-affected zone, leading to minimal deformation from heat conduction.

The workpiece can be placed in a closed environment, such as a vacuum or controlled gas environment.

High-speed welding can be easily achieved through automation, and the process can be controlled by digital or computer means.

With perforated welding, the weld bead can have a depth-to-width ratio of up to 10:1.

It is not affected by magnetic fields, unlike arc and electron beam welding, and allows for accurate alignment of the workpieces.

A wide range of materials can be welded, including dissimilar materials.

There is no need for electrodes, avoiding any issues with contamination or damage.

Since it is a non-contact welding process, there is minimal loss and deformation of machines and tools. No vacuum or X-ray protection is required.

The laser beam can be easily redirected to multiple workstations.

When welding thin materials or small diameter wires, there is no risk of remelting, as is common in arc welding.

The process parameters for welding a single pass of a 32mm thick plate have been verified and can reduce the time needed for thick plate welding and eliminate the need for filler metal.

The laser beam can be focused on small, closely spaced areas, making it ideal for welding small parts.

The laser beam is easily guided and aligned using optical instruments, and can be positioned at a distance from the workpiece, easily navigating around obstacles.

This flexibility allows for welding in areas where other welding methods cannot be used.

Laser welding can also be used to join metals with different physical properties, such as varying resistances.

Laser welding offers numerous advantages over traditional resistance welding, including superior welding quality, cost-effectiveness, and benefits.

It has a broad range of applications and is an essential component for future welding processing.

The only drawback is that the initial purchase cost may be relatively high.

However, its capabilities, production efficiency, and benefits far surpass those of any other welding equipment.