Have you ever wondered how stainless steel achieves that flawless, mirror-like finish? This article dives into the essential techniques for polishing stainless steel, covering everything from mechanical and chemical processing to advanced texturing methods. Discover how each technique not only enhances the metal’s appearance but also its functionality and durability. Get ready to learn the key steps to achieve that perfect shine and understand the science behind each method.

The diverse surface treatments of stainless steel have expanded its range of applications.

Each type of surface treatment produces a distinct surface, rendering the stainless steel suitable for unique applications.

In the realm of architectural applications, the significance of surface treatment for stainless steel is manifold.

There are approximately five different types of surface treatments that can be utilized for stainless steel. These treatments can also be combined together to produce a greater variety of finished products.

The five categories of surface processing for stainless steel are:

There are also some specialized surface processing techniques available. However, regardless of the chosen method, the following steps should be followed:

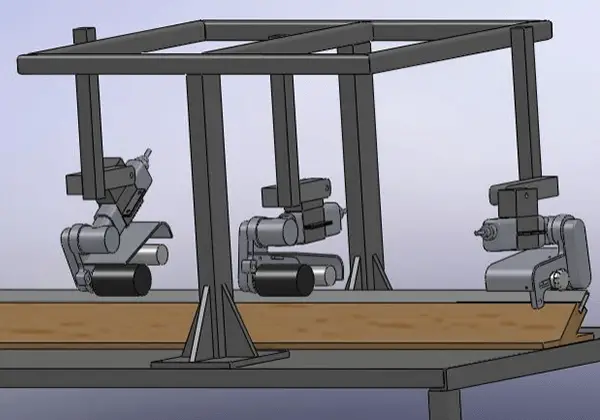

There are three basic rolling surface processing techniques for plates and strips, which are represented by the production process of plates and strips:

In addition to these techniques, there is a special surface processing technique called 2B bright annealing. This technique produces a highly reflective surface by rolling the steel with a polishing roller and then annealing it in a controlled atmosphere. Bright annealing retains its reflective surface and does not produce oxide scale. Since no oxidation reaction occurs during bright annealing, there is no need for further acid pickling and passivation treatment.

No.3 surface processing is represented by 3A and 3B.

3A: The surface is uniformly ground, and the abrasive particle size is 80~.

3B: This technique involves rough polishing the surface with uniform straight lines. It is typically achieved by polishing an abrasive belt with a particle size of 180 to 200 on a 2A or 2B plate.

No.4: This surface processing creates a unidirectional surface with poor reflectivity, and it is widely used in architectural applications. The process involves coarse abrasive polishing followed by grinding with an abrasive of 180 particle size.

No.5: This is an improvement over No.4 and involves polishing the No.4 surface with a Tampico polishing brush in an abrasive and oil medium. This surface processing is not included in “British Standard 1449” but can be found in American standards.

No.6: This is called bright polishing and is used to polish a surface that has been finely ground but still has wear scars. Usually, a 2A or 2B board is used along with a fiber or cloth polishing wheel and the corresponding polishing paste.

No.7: This surface processing results in a highly reflective mirror surface, which is often called a mirror surface. Stainless steel is polished continuously with a fine abrasive and then polished with a very fine polishing paste.

It should be noted in architectural applications that this type of surface is prone to leaving fingerprints if used in areas with high human traffic or where people touch frequently. While fingerprints can be wiped off, they can affect the aesthetics of the surface.

The classification of surface finishing can be divided into two types: rolled surface processing and polished surface processing. These types indicate the level of smoothness that can be achieved.

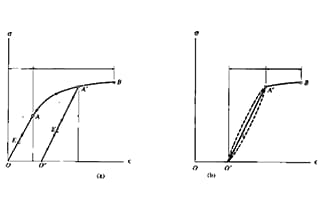

Another effective way to express surface smoothness is by measuring surface roughness.

The standard method for measuring surface roughness is called CLA (Central Line Average). A measuring instrument is used to move laterally on the surface of the steel plate and record changes in peak and valley. The smaller the CLA number, the smoother the surface. The table below shows the final results of different grades based on the surface finishing and CLA numbers.

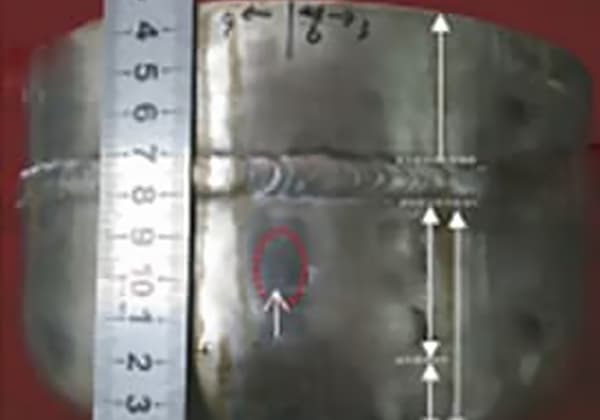

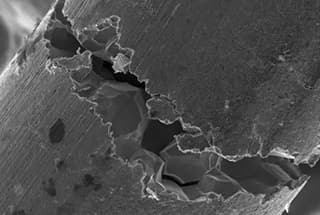

It is important to remember that during the grinding process, the use of abrasive paper or belt essentially performs a polishing and cutting operation, leaving very fine lines on the surface of the steel plate.

We have experienced difficulties when using alumina as an abrasive due to pressure issues. Any abrasive parts of the equipment, including abrasive belts and wheels, should not be used on non-stainless steel materials before being used on stainless steel. This is because it can lead to contamination of the stainless steel surface.

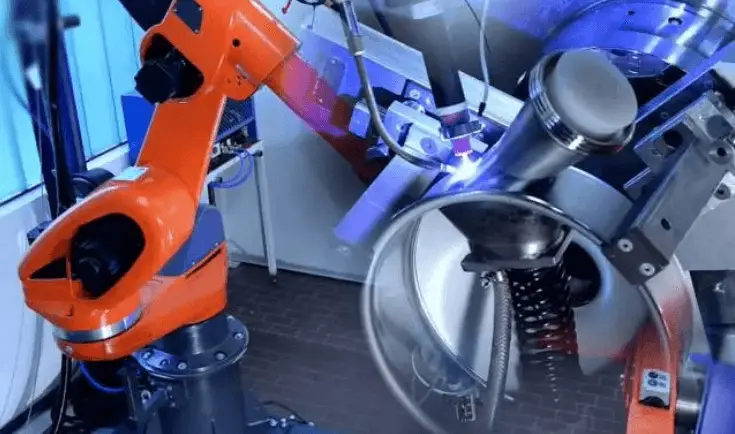

Electrolytic polishing is a metal removal process in which stainless steel is used as the anode in an electrolyte solution, and the metal is removed from the surface after an electric current is applied. This process is commonly used for machining parts with complex shapes that are difficult to polish using conventional methods.

The process is often used on the surface of cold-rolled steel sheet because it has a smoother surface than hot-rolled steel sheet. However, electrolytic polishing can make surface impurities more visible, especially in stabilized materials like Titanium and Niobium, which can cause differences in the welding zone due to granular impurities.

This technique is effective for removing small welding scars and sharp edges, as it preferentially dissolves surface protrusions. The electrolytic polishing process involves immersing stainless steel in a heated liquid, and the liquid’s proportions involve many proprietary and patented technologies. Electrolytic polishing of austenitic stainless steel is particularly successful.

There are numerous patterns that can be applied to stainless steel, and the advantages of creating steel plates with textured or patterned surfaces are as follows:

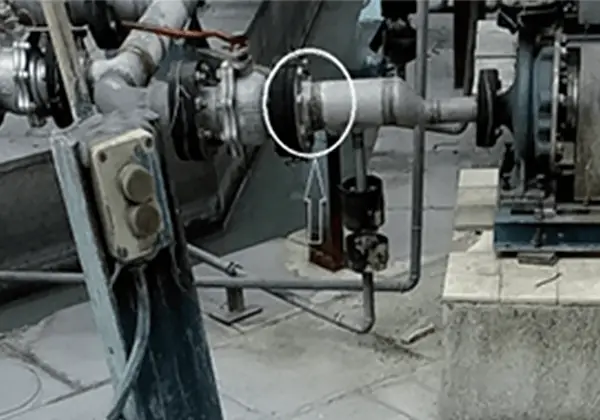

Rough surface processing is one of the most commonly used surface treatments. It involves polishing the surface of a steel plate with a nylon abrasive belt or brush after polishing or bright annealing.