Imagine your factory’s production line suddenly grinds to a halt due to a leak in a crucial pipeline. How do you fix it without risking further damage or downtime? This article delves into six essential welding techniques for stopping leaks, highlighting practical methods and safety measures. From hammering to riveting, you’ll learn strategies to manage leaks efficiently and ensure safety in high-pressure, hazardous environments. Prepare to equip yourself with the knowledge to tackle leaks effectively and keep your production running smoothly.

In industrial production, equipment that runs continuously may experience leaks for various reasons, such as leaks in pipes, valves, containers, etc. These leaks can negatively impact production stability, reduce product quality, and result in environmental pollution and waste. Furthermore, leaks of hazardous media such as toxic gases and grease can pose serious threats to production safety and the surrounding environment.

For instance, the Qingdao Huangdao oil pipeline explosion on November 22, 2013, and the Tianjin Binhai New Area dangerous goods warehouse explosion on August 2, 2015, resulted in significant loss of life and property for the country and its people, both of which were caused by media leaks.

Therefore, it is crucial to address leaks of industrial products in a timely manner. However, repairing leaks in equipment containing flammable, explosive substances, or toxic chemicals under pressure presents a technical challenge.

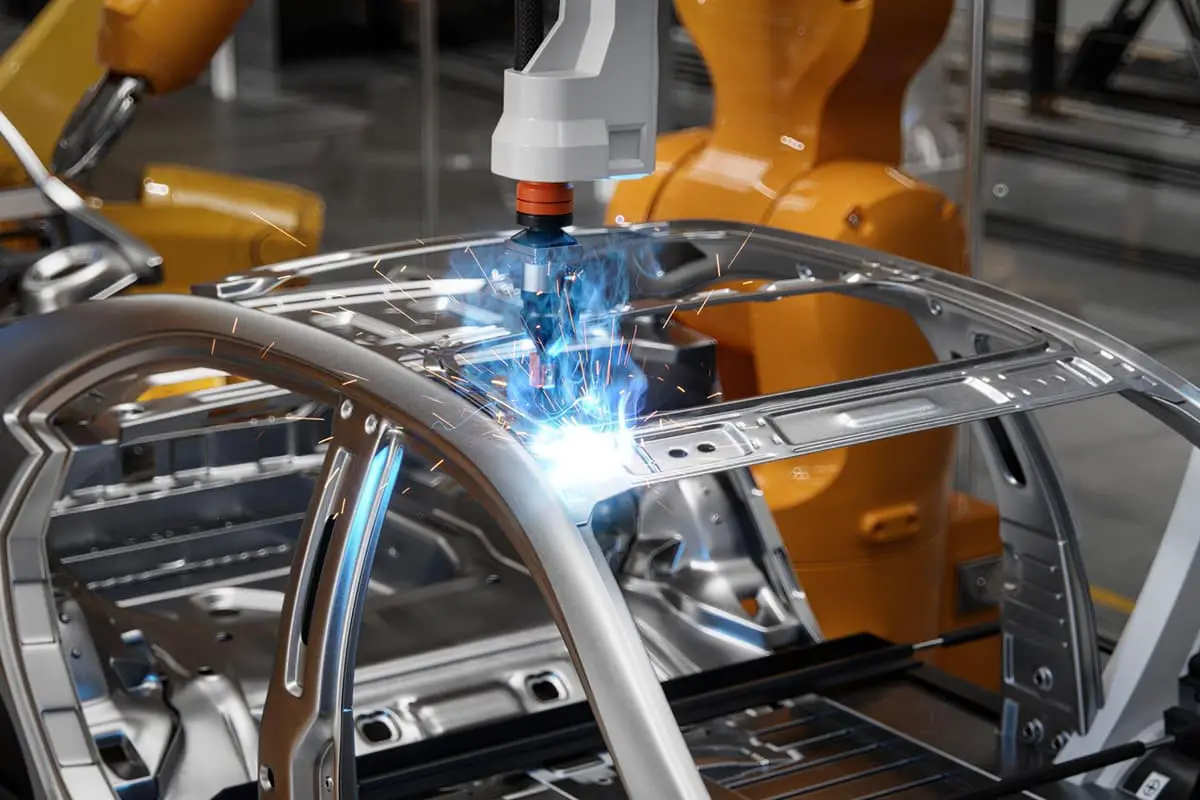

The repair of leaks in equipment with pressure, oil, or toxic substances requires special welding under hazardous conditions, which differs from normal welding procedures and places a strong emphasis on safety.

Before welding, safety measures must be put in place to prevent accidents and ensure the safety of the workplace, welders, and other workers. Welders must be experienced and skilled, and welding engineers with extensive technical expertise must provide guidance for safe operation.

For instance, when repairing a certain type of oil tank, the capacity, ignition point, pressure, etc. of the oil inside must be known, and the welding process must not pose a threat to personal safety or cause larger safety incidents.

Therefore, the following steps must be taken before and during welding construction to ensure safety:

The following are several commonly used methods for stopping leaks in welding, which are commonly used in engineering practice and are worth learning and improving.

This method is suitable for welding cracks, sand holes, and blowholes in low-pressure vessels and pipes.

It is recommended to use small diameter electrodes as much as possible for welding. The welding current must strictly adhere to the process requirements.

The preferred welding method is the fast welding method. The heat from the arc should be utilized to heat the area around the leak.

Once the arc is turned off, the leakage point should be quickly compressed using a hammer or pointed shovel, and the weld should be pounded while welding.

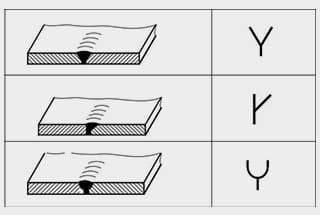

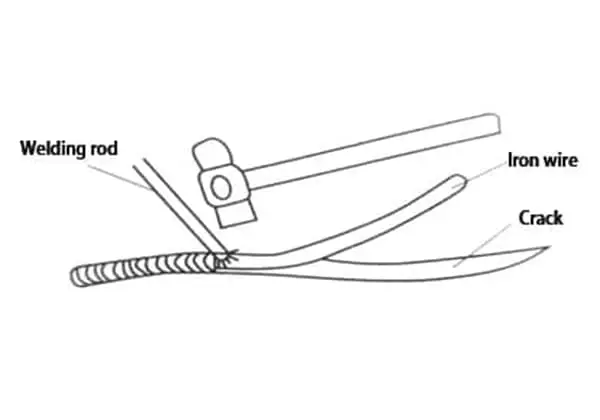

When cracks are wide or the diameter of sand holes and air holes is large, it can be challenging to use techniques such as hammering, twisting, and pressing.

In such cases, the cracks or holes can be plugged using appropriate iron wires or welding rods to reduce the pressure and flow of the leak, and then rapid welding can be performed using a small current.

The key aspect of this method is that only one section should be plugged at a time, and then rapid welding can be carried out.

This is illustrated in Figure 1.

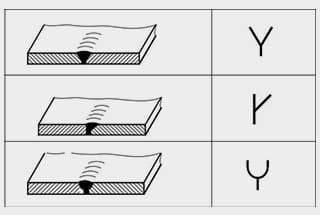

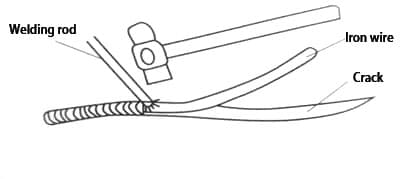

Some leaks are caused by factors such as corrosion, wear, and thinning. In such cases, direct welding of the leak should be avoided as it may cause even bigger leaks.

Instead, spot welding should be performed at appropriate positions next to or below the leak. These areas should be free of leaks.

To start, a molten pool should be created, and then the leak should be gradually reduced by welding point by point, similar to a swallow’s mud trap.

Finally, the leak should be sealed using a suitable welding current and a small diameter electrode, as illustrated in Figure 2.

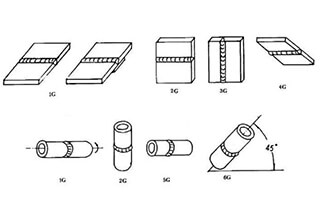

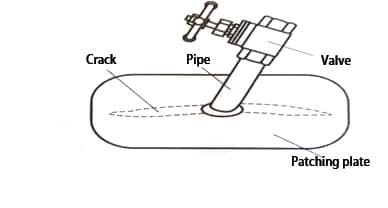

This method is suitable for welding with large leakage areas, high flow rates, or high pressures, as shown in Figure 3.

To address the leak, a complementary plate with a closure device should be created based on the shape of the leak.

For more significant leaks, an interceptor in the form of a section of diversion pipe with a valve installed should be used.

For smaller leaks, a nut can be pre-welded onto the repair plate.

The size of the patching plate should be larger than the leak. The closure device on the patching plate should be positioned facing the leak.

A bead of sealant should be applied to the side of the patching plate that contacts the leak to allow the leaking medium to flow out through a guide pipe and reduce the leakage around the patching plate.

Once the repair plate is welded, the valve should be closed or the bolts tightened.

When a pipeline leaks in a large area due to corrosion or wear, a sleeve tube with the same diameter or just large enough to hold the leaking pipeline can be used. The length of the sleeve tube should be determined based on the size of the leak.

The sleeve pipe should be cut into two halves symmetrically, and a deflector pipe should be welded onto it. The welding method should be the same as the deflector welding method.

When welding, the seam between the pipe and the sleeve should be welded first, followed by the seam of the sleeve, as shown in Figure 4.

Continuous welding should not be used. The weld temperature should not exceed an appropriate level.

The spot welding method should be applied with simultaneous cooling.

For instance, after spot welding at several points, immediately cool the welding spots with cotton gauze dipped in water.

At times, a combination of these methods may be necessary to effectively stop leaks. Welding leak stoppage requires versatility to guarantee its success.

However, not all metal materials are suitable for welding leak stoppage. Only low carbon steel and low alloy steel can utilize these leak stoppage methods.

Austenitic stainless steel can only be repaired by welding if the base metal near the leak point can undergo significant plastic deformation. Otherwise, welding is not an option.

The medium in heat-resistant steel pipes is typically high-temperature, high-pressure steam.

Leaks that have developed after long-term use cannot be repaired under pressure. Welding should not be used to repair low temperature steel under pressure.

All of these welding methods are temporary solutions and do not provide the same metal mechanical properties as strict welding.

When the equipment is not under pressure or not carrying a medium, the temporary leak blocking welding should be fully removed, and the equipment should be rewelded or repaired in another manner to meet product requirements.

With the advancement of modern production, welding leak stoppage technology has become a crucial emergency technique in the continuous production process.

Dealing with a leak requires a certain amount of time and the leak should be fully replaced at a later stage.

The use of leak stoppage technology should be adaptable.

Multiple methods can be employed to address a leak, with the goal of preventing leaks after welding.