The English term “screw” is a word that has undergone significant changes in meaning over the past few centuries.

Beyond just its name, the humble screw, from its invention to the standardization of being tightened clockwise and loosened counterclockwise, has spanned thousands of years.

Have you ever pondered why screws are specifically tightened clockwise?

It was a friend of Plato who invented the screw.

The six simplest mechanical tools are: screw, inclined plane, lever, pulley, wedge, wheel, and axle.

Among these six simple machines, the screw is essentially an axis with a helical surface winding around it. To this day, screws have developed standardized sizes. The typical method of using a screw involves tightening it by turning it clockwise (opposite for loosening).

The predominance of clockwise tightening is mainly determined by right-handedness.

Initially, screws were handcrafted, resulting in inconsistent fine detail, often depending on the craftsman’s preference.

By the mid-16th century, French court engineer Jaques Besson invented the lathe capable of cutting screw threads, a technology that took 100 years to spread. In 1797, the Englishman Henry Maudsley invented the modern lathe, significantly improving thread precision.

Nevertheless, screw sizes and fineness lacked standardization until 1841. Maudsley’s apprentice, Joseph Whitworth, submitted a paper to the Municipal Engineers Society, advocating for the standardization of screw models.

He proposed two points:

- The thread pitch angle should be standardized at 55°.

- Regardless of the screw’s diameter, a standard number of threads per inch should be adopted.

Manufacturing early screws was challenging, “requiring three cutting tools and two machines.”

To address the manufacturing issues of the British standard, the American William Sellers invented a flat-topped thread in 1864. This minor innovation simplified screw manufacturing to require only one cutting tool and machine, making the process faster, easier, and more cost-effective.

Sellers’ screw threads became popular in the United States and quickly became the standard for American railway companies.

Characteristics of Bolted Joints

Main Variables in the Tightening Process

- Torque (T): The tightening torque applied, measured in Newton meters (N·m);

- Clamping Force (F): The actual axial clamping (compression) force between the joined bodies, measured in Newtons (N);

- Friction Coefficient (U): The torque coefficient consumed by the bolt head and thread pair, among others;

- Rotation Angle (A): The thread angle that the bolt needs to turn based on a certain applied torque, to achieve a certain axial elongation or compression of the joined parts.

Methods of Bolt Tightening Control

- Torque Control Method

Definition: A control method that stops tightening immediately once a set torque is reached.

Advantages: The control system is simple, direct, and the tightening quality can easily be checked with a torque sensor or high-precision torque wrench.

Disadvantages: The control precision is not high (pre-tension force error of ±25% or so), and it does not fully utilize the material’s potential.

- Torque-Angle Control Method

Definition: A method that first tightens the bolt to a small torque and then, from this point, tightens it a specified angle.

Advantages: High axial pre-tension force accuracy (±15%), achieving higher axial pre-tension forces, with values closely distributed around the mean.

Disadvantages: The control system is more complex, requiring measurement of both torque and angle; and the quality inspection department might find it challenging to identify an appropriate method to check the tightening results.

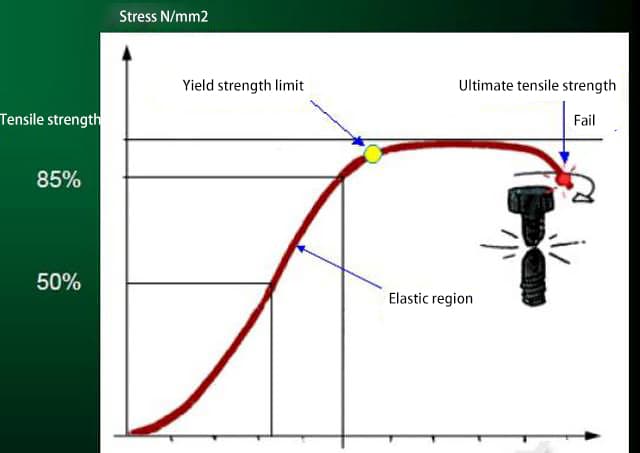

- Yield Point Control Method

Definition: A method that stops tightening once the bolt is tightened to its yield point.

Advantages: Very high tightening precision, with pre-tension force error controllable within ±8%; however, its accuracy mainly depends on the bolt’s own yield strength.

Disadvantages: The tightening process requires dynamic, continuous calculation and judgment of the torque and rotation angle curve’s slope, demanding high real-time performance and computation speed from the control system.