1. Preface

The camshaft is a crucial component in the valve train of an internal combustion engine. It is responsible for regulating the opening and closing of valves in accordance with a specific working sequence and valve phase, ensuring that the valves have adequate lift. As a result, it plays a decisive role in the overall performance of the valve train.

In a four-stroke engine, the rotational speed of the camshaft is half that of the crankshaft. Consequently, the camshaft rotates at a very high speed and must withstand significant torque.

During operation, the cam surface and the rocker arm or tappet experience high periodic contact stress and rapid relative sliding speed. As a result, the camshaft must possess sufficient toughness and rigidity, while the cam surface should have good wear resistance and impact resistance.

2. Research background

The Model M product is a large-scale diesel engine designed for marine use. The camshaft of this product is made of Cf53 steel.

During the initial tensile performance testing of the camshaft body, the yield strength was found to be low. However, after the supplier made adjustments to the heat treatment process, the yield strength met the required standards, while the tensile strength remained low (as shown in Table 1).

Table 1 mechanical property test of Cf53 steel camshaft

| Project | Rm/MPa | Rp0.2/MPa |

| Standard value | 710~850 | ≥400 |

| First test | 717 | 358 |

| Second test | 685 | 408 |

Furthermore, during daily production, the camshaft made of Cf53 steel (equivalent to 55 steel) exhibits the issue of low hardness, measuring below 200 HBW.

To address the aforementioned quality problems, we conducted an investigation and analysis of the production site belonging to the supplier company responsible for manufacturing the M-type camshaft in the early stages. We have put forward measures for improvement, which involve the adjustment of process parameters, including normalizing equipment, normalizing temperature, and cooling speed.

See Table 2 for the process adjustment scheme.

Table 2 adjustment scheme for heat treatment process of Cf53 steel camshaft

| Project | Heat treatment facilities | Process route | Cooling method |

| Before adjustment | Trolley furnace | 820 ℃ normalizing | Forced air cooling |

| After adjustment | Push plate normalizing wire | 840 ℃ normalizing | Strong wind cold |

This post analyzes the physical and chemical properties of the body material of the improved Cf53 steel camshaft and studies the effect of the normalizing process on the mechanical properties of the Cf53 steel camshaft. The goal is to provide a reasonable process plan to enhance the camshaft’s comprehensive properties.

3. Material analysis

3.1 Chemical composition

The chemical composition of the camshaft was inspected, and the results are shown in Table 3, which meet the requirements of material specification: Steel camshaft (enterprise standard) Q / WCG 610.22.

Table 3 chemical composition of cf53 steel camshaft (mass fraction) (%)

| Project | C | Si | Mn | Cr | Ni | P | S |

| Standard value | 0.52~0.57 | 0.15~0.35 | 0.60~0.80 | ≤0.35 | ≤0.30 | ≤0.025 | ≤0.035 |

| Detection value | 0.561 | 0.241 | 0.749 | 0.212 | 0.011 | 0.009 | 0.010 |

3.2 Mechanical properties

The tensile properties at room temperature were tested on the tensile testing machine in the physical and chemical laboratory (see Fig. 1).

Fig. 1 Tensile property test

And detects the hardness of the camshaft test bar.

See Table 4 for mechanical property test results of camshaft test rod.

Table 4 mechanical property test results of camshaft body

| Project | Heat treatment | Rm/MPa | Rp0.2/MPa | A(%) | Z(%) | HardnessHBW |

| Standard value | normalizing | 710~850 | ≥400 | ≥16 | ≥40 | 214~252 |

| 1 # sample | normalizing | 791 | 429 | 18 | 42 | 222 |

| 2 # sample | normalizing | 753 | 409 | 19 | 47 | 226 |

The inspection indexes meet the requirements of the material specification for Steel camshaft (enterprise standard) Q/WCG 610.22.

Table 1 compares the mechanical property test results of the Cf53 steel camshaft before and after process adjustment. The mechanical properties, especially the tensile strength (RM), show a significant improvement after the process adjustment.

3.3 Metallographic structure of body

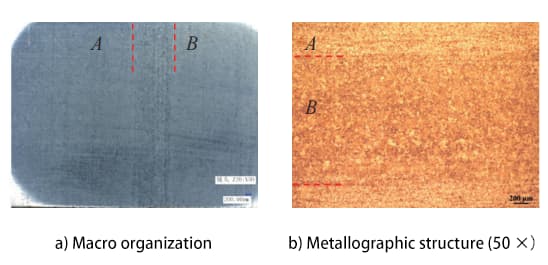

Figure 2a depicts the structure of the cam shaft center of model M after corrosion with 4% nitric acid alcohol. A distinct elongated area with a diameter of 1.5 mm can be observed at position B, which displays completely different colors from the surrounding areas. The metallographic structure of this area is presented in Figure 2b.

The structure characteristics of area B are markedly different from those of area A, indicating the formation of regional segregation.

Fig. 2 macro structure and metallographic structure of cam axis after corrosion

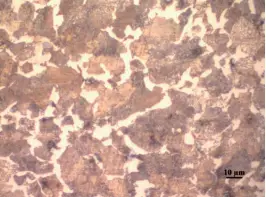

Fig. 3 displays the metallographic structure of area A in the center of the camshaft for model M.

The metallographic microstructure is assessed using the metallographic structure rating diagram and evaluation method for steel die forgings according to GB/T 13320-2007.

The core structure consists of pearlite and ferrite, with a uniform grain size.

The structure rating is grade 2.

As per GB/T 6394-2002 method for determining the average grain size of metals, the actual grain size of austenite is grade 8, which fulfills the technical requirements.

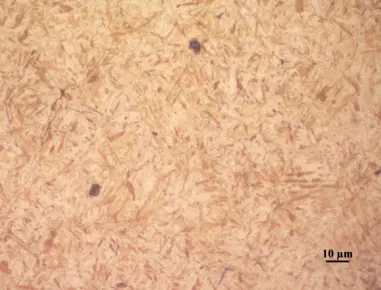

Fig. 4 presents the metallographic structure of area B in the center of the camshaft for model M.

The core structure is primarily pearlite with a small quantity of distributed ferrite, and the pearlite grain is relatively uniform.

Fig. 3 metallographic structure of area 4 of cam shaft center

Fig. 4 metallographic structure of area B of cam shaft center

The central region of the camshaft bar is the final position for crystallization, and it contains high amounts of C, S, P, and other elements. The WC content of Cf53 steel ranges from 0.52% to 0.57%, and the core component’s segregation area is close to the eutectoid point component. Thus, the pearlite structure mainly forms, and only a small amount of ferrite structure is formed.

According to the GB/T 1979-2001 structural steel macrostructure defect rating diagram, the center segregation is rated as grade 1, which falls within the allowable range of technical requirements.

Therefore, it is crucial to control the segregation area of the camshaft center, improve the molten steel’s purity, adopt a reasonable pouring process, and use a large forging ratio during the forging and rolling of the bar blank.

Since severe segregation can significantly impact steel quality, segregation defect inspections should be reasonably controlled during the incoming bar material inspection to ensure the billet’s quality.

3.4 Metallographic structure of surface induction hardening layer

See Table 5 for the surface induction hardening layer depth and hardness test results of cam peach tip, base circle and support Journal (see Fig. 5).

Table 5 detection results of camshaft induction paint fire layer

| Peach tip | Base circle | Bearing journal | ||||

| Quench-hardened case/mm | HardnessHRC | Quench-hardened case/mm | HardnessHRC | Quench-hardened case/mm | HardnessHRC | |

| Criterion | 1.5~5.5 | 59~63 | 1.5~3.5 | ≥55 | 1.5~3.5 | ≥55 |

| Test | 5.0 | 61.2 | 3.5 | 63.4 | 3.5 | 63.2 |

Meet the standard requirements.

The metallographic structure of the induction hardening layer is shown in Figure 6.

The evaluation of this structure is conducted according to QC/T 502-1999, which is the standard for metallographic inspection of automotive induction hardening parts.

The observed structure is identified as fine needle martensite, rated as grade 4, and satisfies the requirements of standard 20200718.

Fig. 6 metallographic structure of induction hardening layer

3.5 Conclusion

After analyzing the M-type camshaft made of Cf53 steel following process adjustment, the following conclusions can be drawn:

- The chemical composition of the camshaft model M meets the required standards.

- By increasing the normalizing cooling speed, the mechanical properties (tensile strength, yield strength, elongation, reduction of area, and hardness) of the camshaft can be improved.

- The metallographic structure of the camshaft body of model M also meets the necessary standards. There is a level 1 central segregation area at the center of the camshaft body with a diameter of 1.5mm, distributed along the center line of the camshaft.

- The metallographic structure of the induction hardening layer of the M-type camshaft is also within the required specifications.

4. Improvement suggestions

- The supplier is required to adhere to the normalization process for the Cf53 steel M-type camshaft as per the guidelines provided during the adjustment and trial production phases. Additionally, they must enhance the relevant process documentation.

- The inspection of segregation defects must be appropriately managed to ensure the quality of the billet while the bar material is being received at the factory.