Have you ever wondered how to form precise arcs in sheet metal? This article breaks down the process, whether you’re working with small or large radii. You’ll learn about the necessary tools, techniques, and steps to achieve high-quality results. By the end, you’ll have a clear understanding of how to create perfect arcs, enhancing your metalworking skills and efficiency. Dive in to discover the key methods and best practices for sheet metal arc-making.

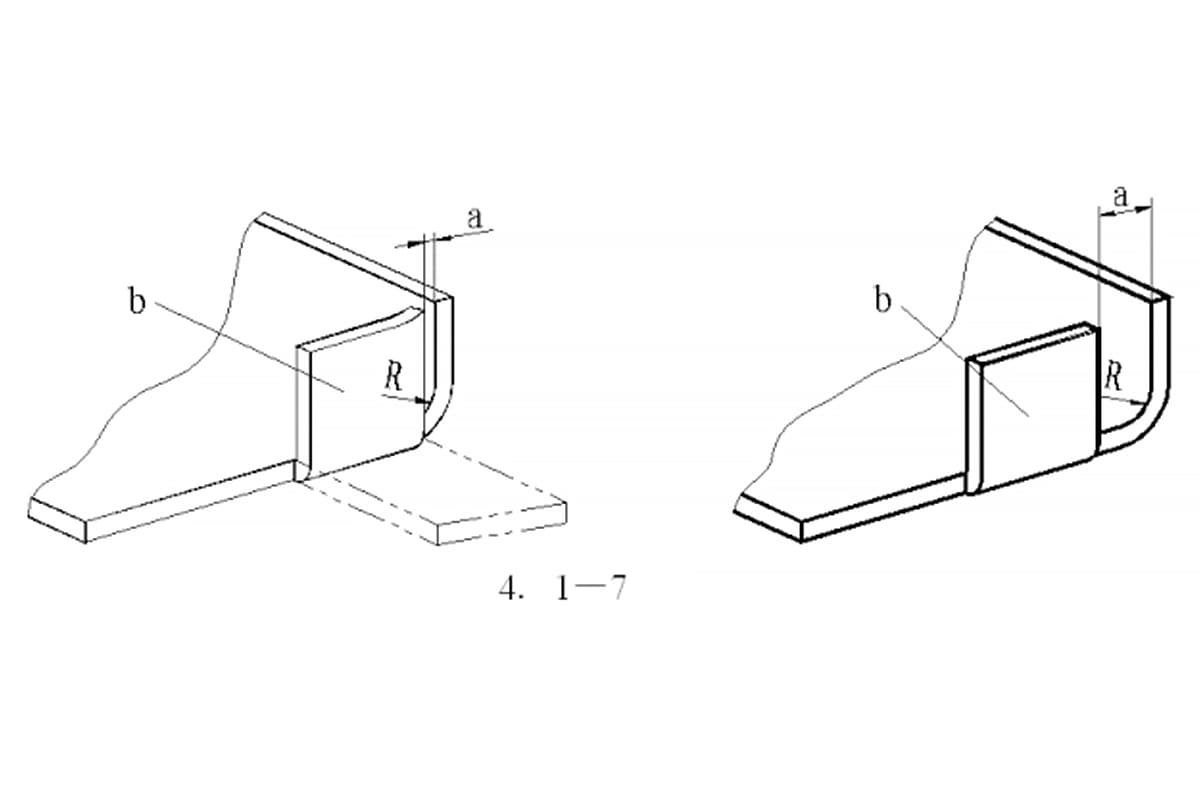

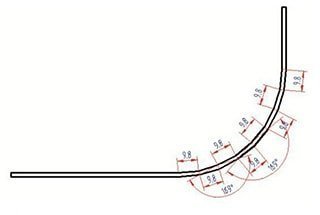

If the bending radius of the arc workpieces is less than R30, they can generally be bent directly using a circular plate bending mold (as shown in Figure 1).

Figure 1

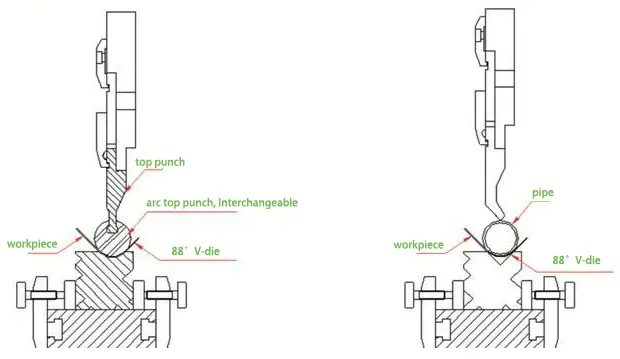

When the upper mold is fixed, it is recommended to use the upper mold fixing method shown in the figure, as it makes disassembly more convenient. This method can also help reduce costs when adding new molds.

The products produced by this process have high precision and accurate sizing, making them suitable for large-scale precision sheet metal parts.

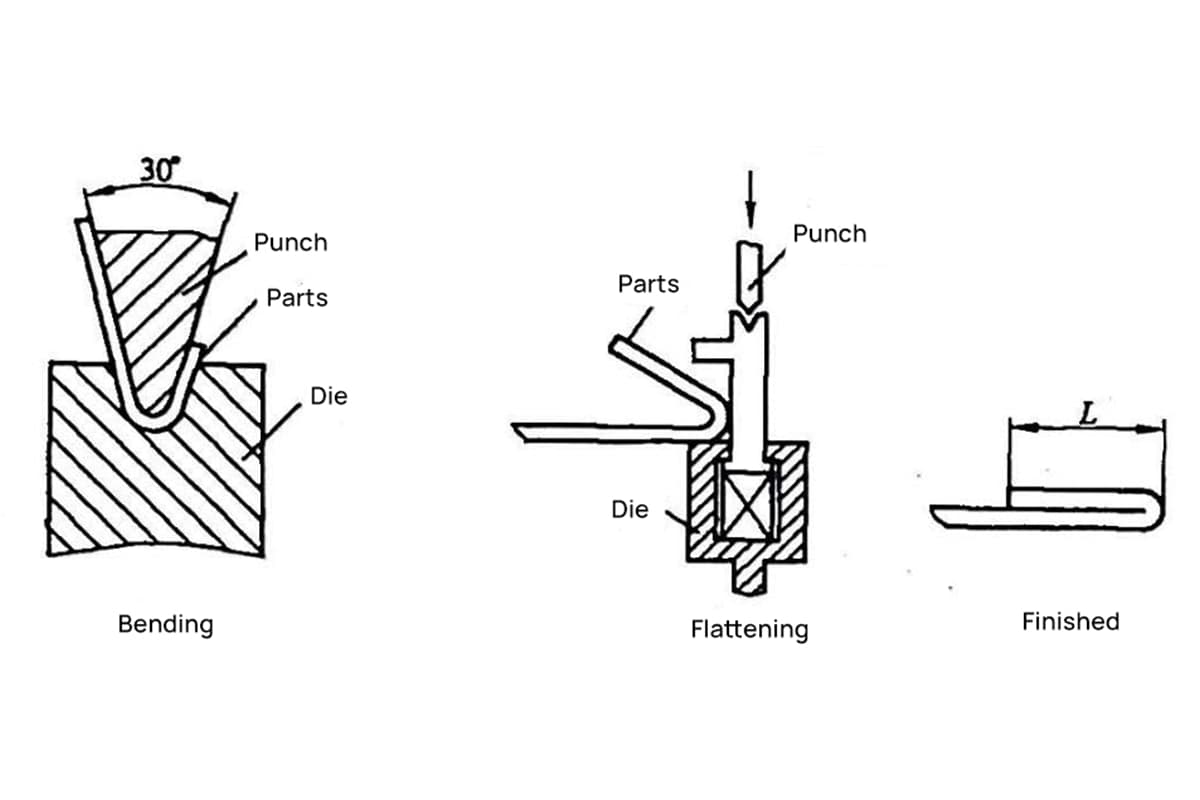

For arc workpieces with a radius smaller than R30 and no strict requirement for size tolerance, a round tube with a diameter equal to the arc of the sheet metal part can be placed directly on the surface of the metal plate. The lower die can then use a V-groove with a width larger than the diameter of the arc, as shown in Figure 2.

By using a common bending upper die tip to press the round pipe onto the sheet metal, the desired forming can be achieved.

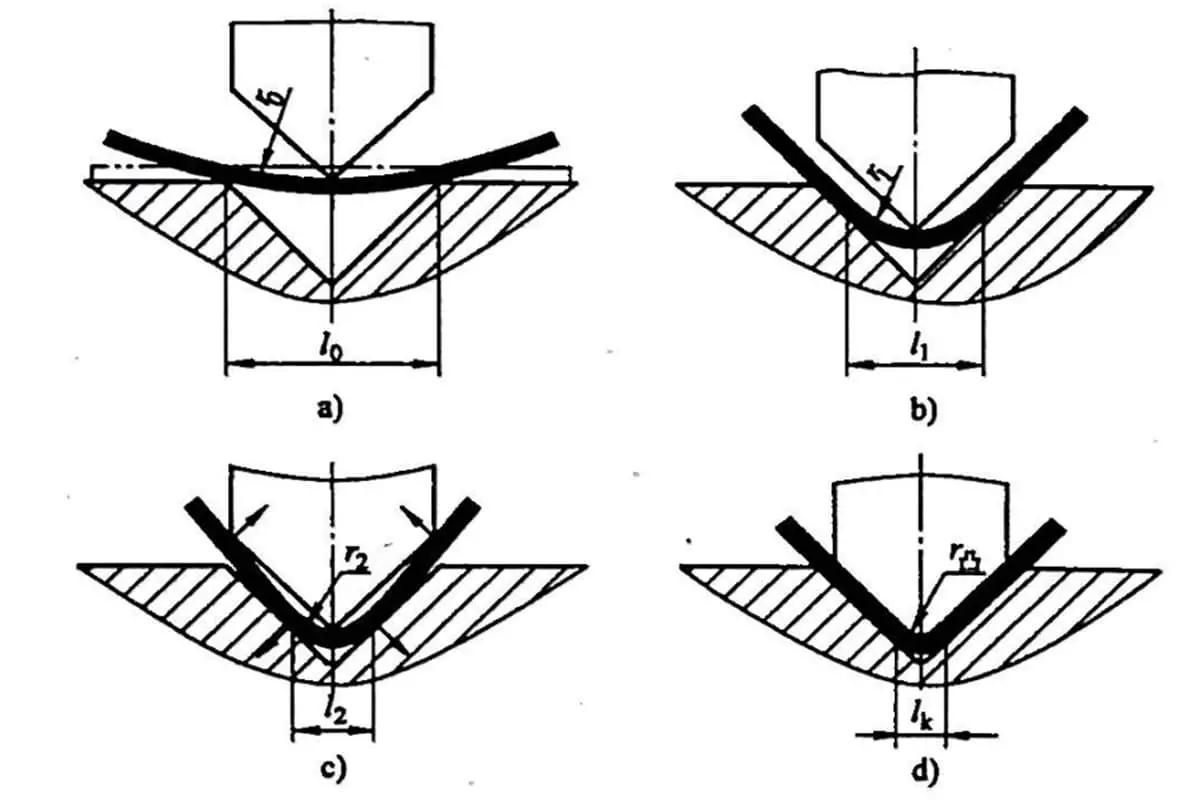

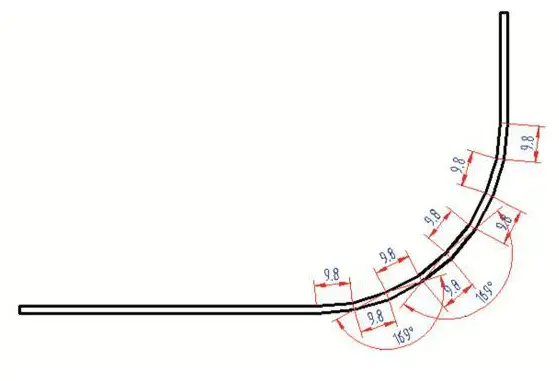

For arc sheet metal with a radius larger than R30, the arc of the segment can be unfolded, and the number of required bending times can be calculated based on the size to achieve the desired shape. This allows for the calculation of the positioning size for each bend.

Next, the angle of each bend can be calculated based on the relationship between the total arc angle and the total number of bends.

When making sheet metal parts using this process, a greater number of bends for the same arc size leads to better results and a smoother surface.

When bending such products, the starting point of the bender ram stroke can be adjusted to increase the bending speed.

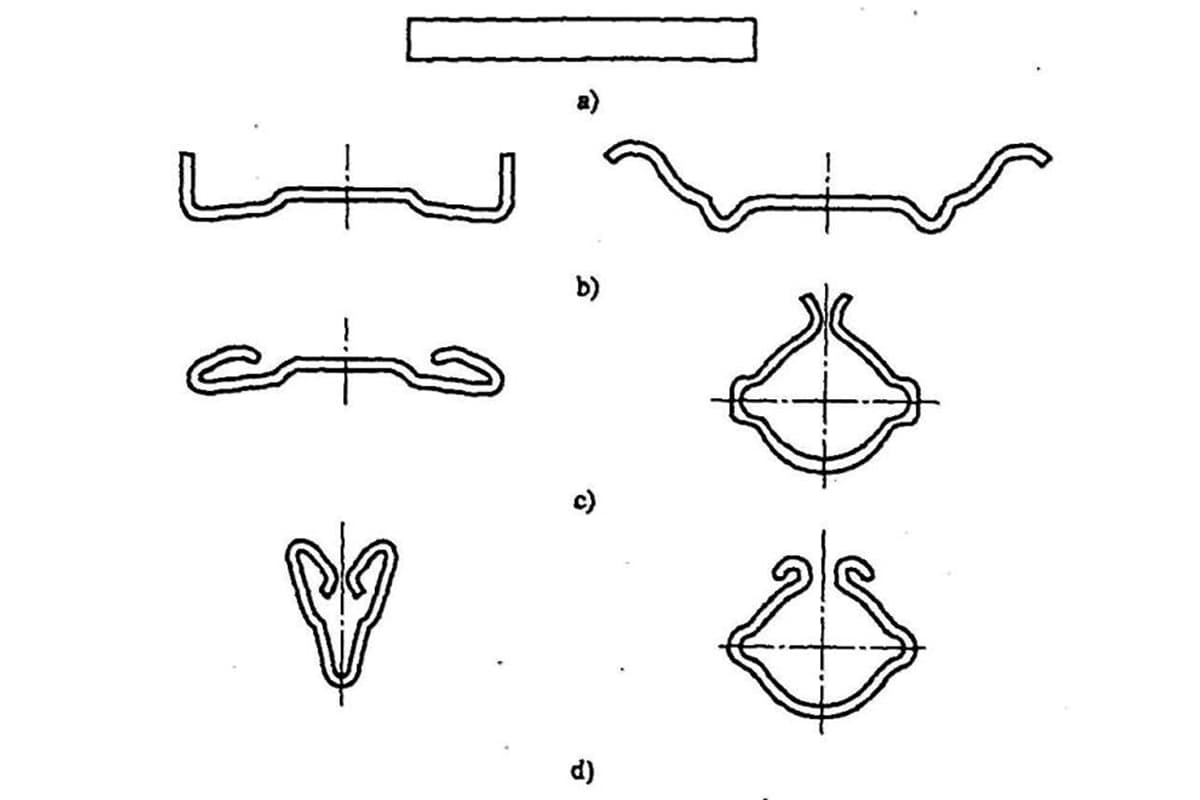

The completed workpiece is shown in the figure below:

Figure 2

To learn more about achieving large radius in sheet metal parts, you can read an article about bump bending.