Ever wondered why burrs appear on aluminum plates during fiber laser cutting? This article dives into the factors causing burrs and how to minimize them. By adjusting laser power, gas type, and nozzle height, you can achieve smoother cuts. The latest laser technology advancements also offer new solutions. Learn practical tips to enhance your cutting process and improve product quality.

With the growing market competition and demand, aluminum products have become widely utilized in various industries, such as the automotive, electronics, precision hardware, and mechanical equipment sectors.

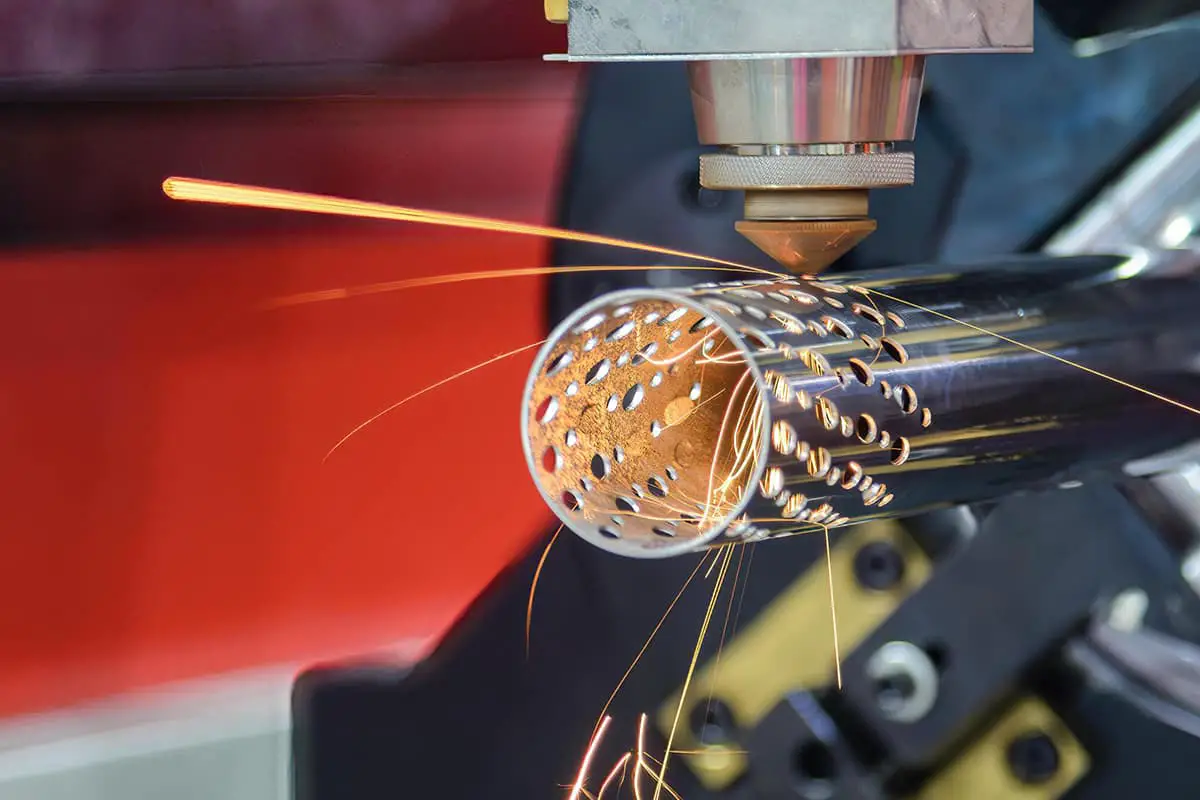

The optical fiber laser processing machine is crucial for efficient aluminum plate cutting production.

As a result, improving the section cutting quality of aluminum plates has become a widely discussed topic of concern.

1. Main influencing factors of burr in aluminum plate cutting

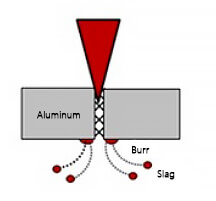

Compared to CO2 lasers, optical fiber lasers have higher concentration and a narrower cutting gap. As a result, during processing, the air flow rate is high and burrs tend to occur at the bottom of the material. For high-quality cutting, a carbon dioxide cutting machine is recommended.

Table 1. laser beam characteristics

| Classfication | Fiber laser | CO2 laser | |

|---|---|---|---|

| Solid state laser | Gas laser | ||

| Excitation media | Active optical fiber | Mixed gas (carbon dioxide, etc.) | |

| Excitation origin | Semiconductor laser | Discharge | |

| Wavelength | 1.07μm (near infrared) | About 106μm (far infrared) | |

| Concentrating property | Spot diameter | About 10μm | About 100μm |

| Vibration efficiency | Electrical efficiency | More than 30% | About 10% |

| Electricity fees | High | Low | |

| Generator structure | High fiber internal resonance (without reflector) | Refract with reflector | |

| Laser transmission | Transmission fiber (without reflector) | Refract with reflector | |

| Characteristic |  |  | |

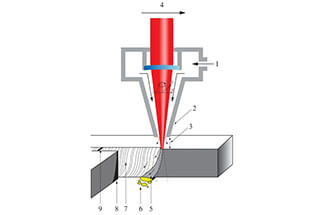

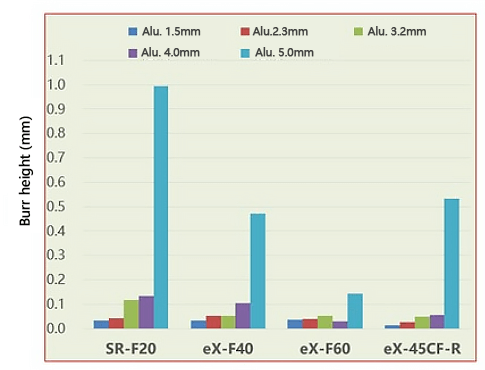

2. Effect of generator output power on burr

According to the thickness of the aluminum plate, the burr can be minimized by selecting the power of the optical fiber laser appropriately.

Fig. 2 laser power and burr height

Table 2. Recommended thickness of aluminum plate for different optical fiber output power

| Optical output power | Recommended plate thickness |

|---|---|

| 2KW | T1.0mm-2.3mm |

| 4kW | T2.3mm-3.0mm |

| 6kW | T3.0mm-4.0mm |

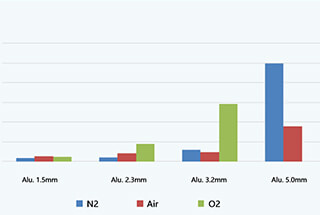

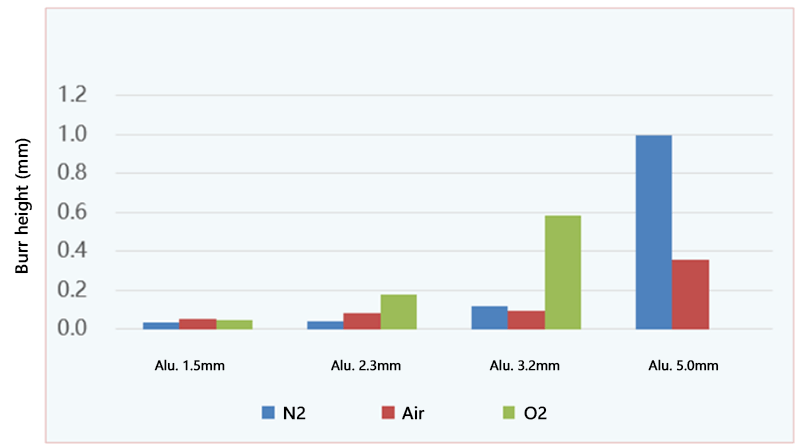

3. Influence of processing gas type on burr of aluminum plate

The burrs resulting from aluminum plate processing with nitrogen are small, soft, and easy to remove, but the operation cost is high.

On the other hand, air cutting results in larger burrs that are difficult to remove, but the operation cost is low. The burrs produced from oxygen cutting are the largest and the least practical to use.

To ensure the desired quality of the aluminum plate sections, the processing gas should be chosen judiciously based on the quality requirements.

Fig. 3 Comparison of processing gas types

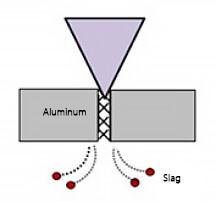

4. Effect of machining gas flow on burr (nozzle height)

To reduce burrs, the height of the nozzle can be reduced and the gas flow increased during the cutting of holes and corners. When cutting the periphery, the nozzle height should be returned to normal.

When cutting small holes and corners, lowering the nozzle height can also help reduce burrs.

Aluminum plate: t 2.0mm

Fig. 4 quality comparison of changing nozzle height

5. The help of the latest processing head for aluminum plate processing

The zoom speed of traditional processing heads is slow, making it impossible to adjust the nozzle height during processing.

However, the latest cutting heads have fast zoom speed and can maintain the set focus position even as the nozzle height changes. This ability to adjust the nozzle height can help improve the burr of aluminum plates.

Figure 5 new cutting head

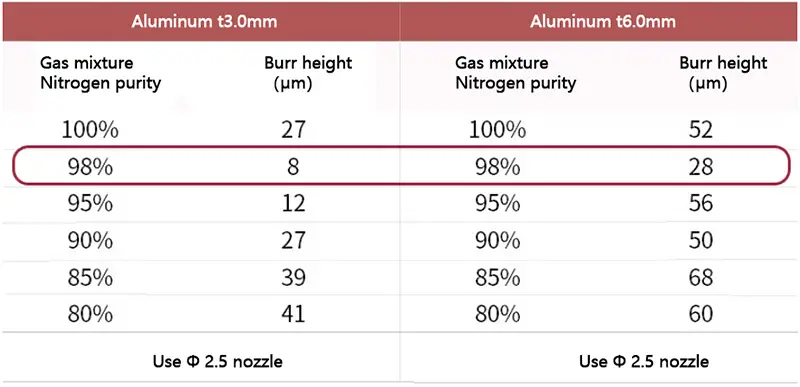

As we have seen, the type of processing gas can affect the height of the burr. How will using an appropriate mixture of gases affect the burr height?

Fig. 6 Effect of mixed gas purity on burr

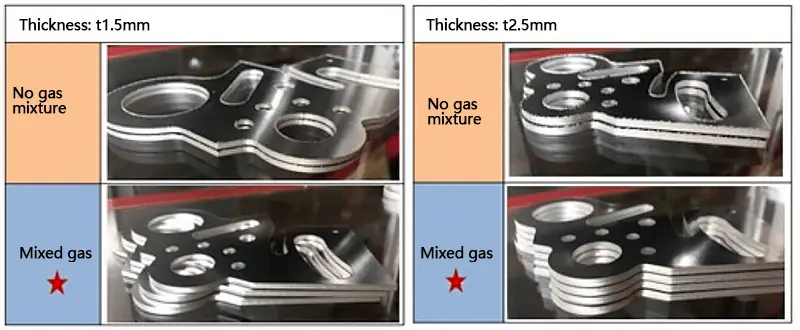

By using an appropriate mix of nitrogen and oxygen, the burr issue of aluminum plates processed by fiber laser cutting machines can be significantly improved.

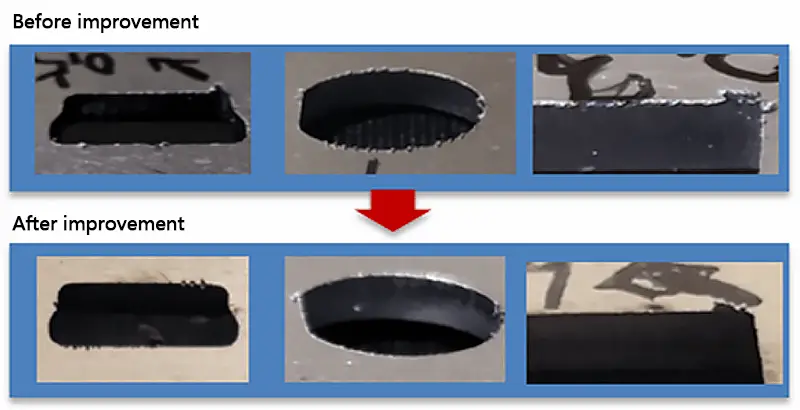

Fig. 7 cross section comparison of mixed gas cutting aluminum plate

This post has outlined the major factors that impact burr in the daily production of aluminum plates processed by fiber laser cutting machines, as well as methods for adjusting them.

We hope this information will be helpful in your future aluminum processing endeavors.