Have you ever wondered how intricate designs are cut into aluminum with such precision? This article explores the fascinating world of laser-cut aluminum, revealing the technology behind it. You’ll learn about the process, its benefits, and real-world applications. Get ready to dive into the magic of laser cutting!

CO2 lasers or fiber lasers can be used to cut thin sheets of non-ferrous metal.

However, when using a carbon dioxide laser, it is necessary to coat the material surface to prevent reflected light from damaging the laser device.

On the other hand, fiber lasers can be used directly for non-ferrous metal cutting.

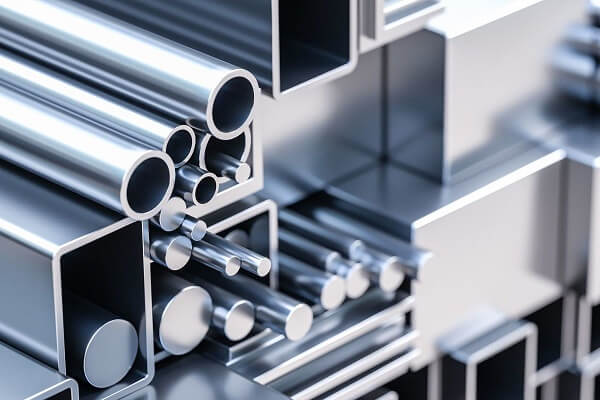

Aluminum can be cut using various cutting machines, such as lasers, plasma, waterjet, or mechanical cutting machines.

Compared to traditional aluminum cutting machines, the main advantage of a laser cutting machine lies in its speed and quality. The processed workpiece is smoother and free of defects.

See also:

The thickness of aluminum plate that can be cut by a laser cutting machine depends on the laser’s power.

A 6000W laser cutting machine can typically cut a maximum thickness of 16mm, while a 4500W laser cutting machine can cut up to 12mm.

However, processing aluminum can be expensive due to its high reflectivity.

Laser cutting works by focusing a high-power density laser beam onto the workpiece, causing the material to quickly melt, vaporize, ablate, or reach its ignition point.

The molten material is then blown away by a high-speed air flow that is coaxial with the beam, resulting in a clean cut.

In recent years, advancements in laser technology have led to increased evaluation of the benefits of laser cutting aluminum.

The laser cutting process allows for faster processing of consistent parts, making it more efficient than traditional methods. This technology greatly reduces processing time and production costs.

The laser cutting equipment available on the market for cutting aluminum plates can be divided into three categories.

The wavelength of the carbon dioxide laser cutting machine is 10.64um, which is easily absorbed by non-metallic materials. This allows for high-quality cutting of materials such as wood, acrylic, PP, and plexiglass.

However, cutting high reflective materials such as aluminum, copper, and silver is less practical due to most of the energy being reflected and lost.

Additionally, the photoelectric conversion rate of CO2 lasers is only about 10%, and the cost of maintenance, including the replacement and supply of liquid nitrogen, electricity consumption, and cooling system support, is high.

This further limits the machine’s utility, as it can only cut aluminum plates up to a thickness of 3mm, which may not meet the needs of most aluminum plate cutting customers.

This is a newly developed fiber laser that takes up less space and consumes less gas compared to the carbon dioxide laser cutting machine. The 1.06um wavelength is also more suitable for cutting metal materials.

Currently, the fiber lasers available in the market are mainly IPG continuous light lasers, which are of high quality but expensive. The limited competition among manufacturers keeps the prices of fiber laser machines high.

Furthermore, if one fiber in the laser is damaged, the entire laser must be replaced, adding to the maintenance costs and making customers hesitant to purchase.

However, with increased competition and technological advancements, the cost of fiber laser cutting machines has been decreasing, making it a more accessible option for a wider range of users.

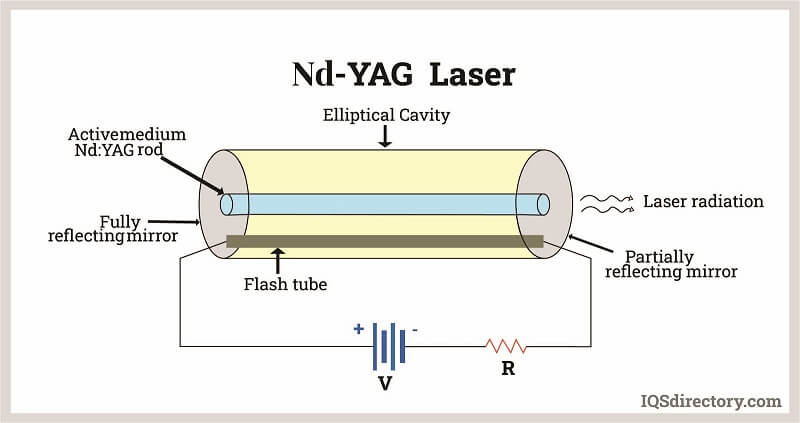

The YAG laser cutting machine has a wavelength of 1.06um, making it also suitable for cutting metal materials.

YAG laser technology is a well-established and widely recognized technology that has been used for a long time in the international community.

Its beam quality and pulsed laser characteristics make it ideal for cutting metal materials, with a high energy utilization rate.

Additionally, its low cost of purchase and use has attracted more and more customers.

The workpieces can be arranged closely, leading to a material savings of 20% to 30%. Additionally, the cutting is done in one step without the need for any subsequent processing.

Laser cutting involves focusing the laser emitted from the laser source into a high-density laser beam through an optical path system.

The laser beam is directed onto the surface of the workpiece, causing it to reach its melting or boiling point.

Simultaneously, a high-pressure gas is used to blow away the molten or vaporized material. As the relative position between the beam and workpiece changes, the material forms a cut, achieving the desired cutting outcome.

Laser cutting uses an invisible beam instead of a traditional mechanical knife, offering advantages such as high precision, fast cutting speeds, versatility in cutting patterns, automatic typesetting, material savings, smooth incisions, and low processing costs.

The use of laser cutting technology is gradually improving or replacing traditional metal cutting equipment. The mechanical part of the laser cutter head does not come into contact with the workpiece during operation, avoiding scratches on the workpiece surface.

Laser cutting also offers fast cutting speeds, smooth and flat incisions, and typically eliminates the need for further processing.

Additionally, laser cutting produces a small heat-affected zone, limited plate deformation, and narrow cutting seams (ranging from 0.1mm to 0.3mm).

The cuts produced have no mechanical stress or shear burr, ensuring high machining precision and protecting the surface of the material.

Laser cutting also allows for NC programming and can process any plan, including cutting an entire board of large format without the need for a mold, resulting in economic and time-saving benefits.

| Thickness | 1 | 2 | 3 | 4 | 5 | 6 | |

|---|---|---|---|---|---|---|---|

| Cutting parameters | Power W | 1800- 2200 | 2000-2300 | 2200- 2400 | 2400- 2800 | 2600- 3000 | 3000 |

| Speed | 2000- 4000 | 2000-3000 | 1000- 2000 | 800- 1000 | 300- 500 | 400 | |

| Gas | N2 | ||||||

| Air pressure KPA | 10 | 15 | 18 | 20 | 20 | 22 | |

| Minimum power change | 80- 100 | 90- 100 | 100 | 100 | 100 | 100 | |

| Hole Cutting parameters | Power W | 2200 | 2200 | 2300 | 2400 | 2400 | 3000 |

| Gas | N2 | O2, N2 | O2 | O2 | O2 | O2 | |

| Air pressure KPA | 150 | 150 | 150 | 150 | 150 | 200 | |

| Frequency HZ | 200 | 200 | 150 | 150 | 150 | 200 | |

| Air proportion | 18 | 18 | 16 | 16 | 16 | 18 | |

| Time S | 0.5 | 1 | 2 | 4 | 5 | 6 | |

From a cost and investment standpoint, fiber laser cutting machines and YAG laser cutting machines are widely used for cutting aluminum and other materials like stainless steel and carbon steel.

These two types of equipment have demonstrated effective results in cutting aluminum plates.

However, due to the highly reflective nature of aluminum, neither fiber laser cutting machines nor YAG laser cutting machines are capable of processing thicker aluminum plates.

It is recommended to use nitrogen while laser cutting aluminum plates to prevent oxidation and retain the material’s color uniformity.

Nitrogen is a better option in comparison to other alternatives.

The cutting thickness of these machines vary, with a 2000W laser capable of cutting 6-8mm, a 4000W laser cutting 12mm, and a 6000W laser cutting 16mm.

Out of the two, fiber laser cutting machines are more suitable for cutting aluminum plates, as their wavelength absorption of 1064nm is more effective.

Based on years of experience in laser cutting aluminum materials, there is still a significant difference between fiber laser cutting machines and YAG laser cutting machines, which can be divided into three categories: cutting quality, cutting speed, and production cost (the production cost mainly refers to the lifespan of the equipment).

Aluminum profile is highly reflective and poses a challenge for both fiber laser cutting machines and YAG laser cutting machines to cut thick aluminum.

Aluminum materials are also prone to burrs during the cutting process, making process control critical for achieving optimal cutting quality.

Proper control of cutting speed is essential. Too fast a cutting speed can result in burrs, while too slow a speed can cause cracks in aluminum materials, affecting the cutting quality.

Generally speaking, for laser cutting equipment with the same power, the cutting speed of a fiber laser cutting machine is faster than that of a YAG laser cutting machine.

The cost of laser cutting is relatively low compared to other cutting processes, but there is a difference between fiber laser cutting machines and YAG laser cutting machines.

The cost of fiber laser cutting is lower due to the frequent replacement of laser lamp accessories in YAG laser cutting machines.

However, in the long run, aluminum material has a detrimental effect on the laser of the fiber laser cutting machine, significantly reducing its service life.

From this perspective, YAG laser cutting machines are more cost-effective.

It’s important to note that aluminum has high reflectivity and low absorption of laser, making it necessary to wear laser protective glasses during processing to ensure safety.

Nitrogen or air can be used to cut 1.6mm aluminum, with the surface of aluminum plate cut with nitrogen being smoother, while there may be slight slag hanging on some sections of aluminum cut with air.

The main auxiliary gases used in laser cutting machines include oxygen, nitrogen, air, and argon.

The products cut by laser will have some burrs, and the solution depends on whether you choose manual or machine grinding.

Manual grinding requires more effort and is less efficient, whereas machine grinding is more cost-effective as it saves labor and results in higher-quality polished products.

(1) The double focal length laser cutting head is a vulnerable component of the laser cutting machine, and its long-term use can lead to damage.

(2) To ensure good cutting performance, it is essential to check the straightness of the fiber laser cutting machine’s track and the verticality of the machine every six months and promptly perform maintenance and troubleshooting if any abnormalities are detected.

(3) Use a vacuum cleaner to remove dust and debris from the machine once a week and ensure that all electrical cabinets are closed to prevent dust buildup.

(4) Regularly inspect the tension of the optical fiber laser cutting machine’s steel belt to avoid any problems during operation that may cause injury or death.

(5) Clean the guide rails of the optical fiber laser cutting machine regularly to remove dust and other debris to ensure smooth operation.

Wipe down the rack and lubricate it frequently to ensure lubrication without any contamination.

Clean and lubricate the guide rails and motor regularly to ensure better machine movement and improved cutting accuracy, which will result in higher quality cut products.

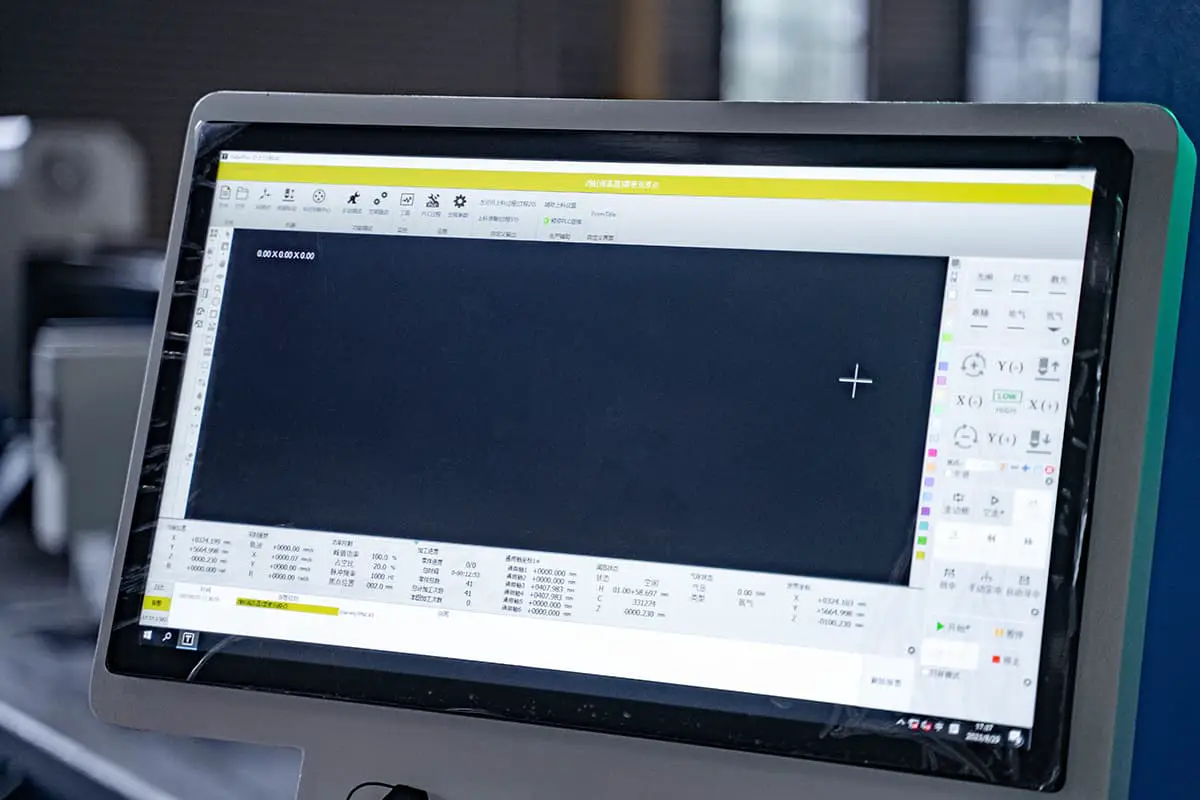

Laser cutting aluminum is a special machine tool that uses laser technology to cut various graphics on pipe fittings and profiles.

It is a high-tech product that integrates numerical control technology, laser cutting, and precision machinery.

With its specialized, high-speed, high-precision, efficient, and cost-effective characteristics, it is a valuable tool in the non-contact metal pipe processing industry.

So, what are its advantages in the construction industry?

Gas Used: Nitrogen is primarily used to prevent oxidation on the cutting surface. The purity of the gas should be at least 99.999% for thicker plates. However, when the appearance of the cut surface is not a concern, oxygen can be used for cutting stainless steel, which can result in thicker cuts than with nitrogen.

Gas Pressure: For stainless steel below 10mm, the pressure should be around 10kg and the flow should be high. However, this results in a high consumption of nitrogen and a relatively high cost. For plates above 10mm, the pressure, flow, and dosage are greater.

Cutting Speed: The plate thickness is inversely proportional to the cutting speed. The power of the laser generator also affects the cutting speed. For example, a 4000W laser generator can cut 4mm at a speed of 3000-5000mm/min, while cutting 10mm would be at a speed of 1000mm/min.

Power: The power required for cutting is determined by the manufacturer of the laser cutting machine. If the cutting is not ideal, the operator can adjust the power as necessary, but this requires experimentation and may vary depending on the steel mill of the material.

Focus: The focus position for cutting stainless steel should typically be in the middle of the plate thickness.

It is more challenging to cut aluminum alloys with a laser than stainless steel (SUS). This is because aluminum is reflective and has a high viscosity in its melting state.

For cutting aluminum, air and nitrogen are generally used with a flow rate of 40-50m3/h, and the cutting speed depends on the thickness of the material.

The maximum thickness that can be cut is typically 12mm. For example, with a 6kW laser, the cutting speed for a 4mm aluminum plate is 4000mm/min, while the cutting speed for a 12mm plate is 700mm/min.

It is important to take protective measures against reflection when cutting aluminum. It is highly recommended to wear a mask when cutting aluminum plates.

The image below shows 28mm and 25mm stainless steel samples that have been cut using a laser with high-pressure nitrogen.

The information above pertains to laser cutting aluminum. I hope it proves helpful to you. If you have any thoughts or suggestions, please feel free to leave them in the comment section.