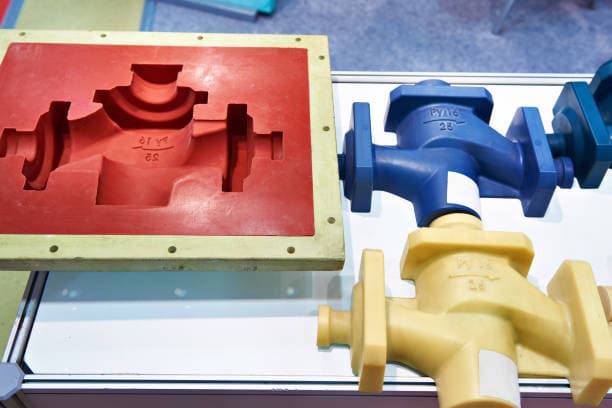

Injection molding, also known as injection moulding, is a manufacturing method that involves injecting molten material into a mold to produce various products.

The advantages of injection molding include fast production speed, high efficiency, automation of operations, the ability to produce a wide range of designs and colors, as well as simple to complex shapes, small to large sizes, and accurate product sizes. It also allows for easy updating of products and the production of complex shapes.

Injection molding is an ideal method for manufacturing complex-shaped products in large quantities and is widely used in various molding processes.

In this process, plastic material is fully melted at a specific temperature and then stirred by a screw. The molten material is then injected into a mold cavity under high pressure and cooled until it solidifies, resulting in a molded product.

This method is particularly suitable for mass production of parts with intricate shapes and is considered one of the most important manufacturing techniques.

Base Information of Injection Molding

The injection molding process can be roughly divided into six stages: mold closing, glue injection, pressure maintaining, cooling, mold opening, and product removal. By repeating this process, products can be produced periodically in batches.

The molding of thermosetting plastics and rubber also includes the same process, but the barrel temperature is lower than that of thermoplastic plastics, and the injection pressure is higher.

The mold is heated, and after the injection of materials, they need to be cured or vulcanized in the mold before removing the film while hot.

Currently, the trend in processing technology is towards high-tech solutions. These technologies include micro injection molding, high filling composite injection molding, water-assisted injection molding, mixed use of various special injection molding processes, foam injection molding, mold technology, simulation technology, and more.

History of Injection Molding

Celluloid, a plastic material, was invented by Alexander Parks in 1851. However, in 1868, a man named Hayat improved it so that it could be processed into finished shapes. Hayat and his brother Isaiah also registered the patent for the first plunger injection machine in 1872. While this machine was relatively simpler than those used in the 20th century, it was still groundbreaking. Essentially working like a huge hypodermic needle, the diffusion cylinder injected plastic into a mold through a heated cylinder.

The second world war, which began in the 1940s, created a huge demand for low-priced, mass-produced products. In 1946, James Watson Hendry, an American inventor, built the first injection molding machine, which made it possible to control the injection speed and quality more accurately. The machine also enabled thorough mixing and injection of color or recycled plastics into raw materials before mixing and injection of materials.

In 1951, the United States developed the first screw-type injection machine, which is still in use today. This device did not apply for a patent. In the 1970s, Hendry went on to develop the first gas-assisted injection molding process, which allowed for the production of complex, hollow products that could be cooled rapidly. This greatly improved design flexibility, strength, and end-point manufacturing components, while reducing production time, cost, weight, and waste.

Injection molding process

Temperature control

1. Barrel temperature:

In the injection molding process, there are three temperatures that need to be controlled: barrel temperature, nozzle temperature, and mold temperature.

The first two temperatures primarily affect the plasticization and flow of the plastics, while the third temperature mainly impacts the cooling and solidification of the plastics.

Each type of plastic has a unique flow temperature. Additionally, even for the same type of plastic, the flow temperature and decomposition temperature may differ due to variations in source or brand, which are caused by differences in average molecular weight and molecular weight distribution.

Furthermore, the plasticizing process of plastic in various injection machines is also different, resulting in variations in the required barrel temperature.

2. Nozzle temperature:

The nozzle temperature is typically set slightly lower than the maximum temperature of the barrel to prevent molten material from dripping out of the straight nozzle, a phenomenon known as “salivation.”

However, it is crucial to avoid setting the nozzle temperature too low, as this may cause the melt to solidify prematurely, resulting in blockages in the nozzle. Additionally, injecting early setting material into the mold cavity may negatively affect the performance of the final product.

3. Mold temperature:

The mold temperature plays a significant role in determining both the internal performance and visible quality of products.

The appropriate mold temperature largely depends on factors such as the plastic’s crystallinity, the size and structure of the product, the desired performance requirements, and other process conditions such as melt temperature, injection speed and pressure, and molding cycle.

Pressure control

The injection molding process involves two types of pressure: plasticizing pressure and injection pressure. These pressures have a direct impact on the plasticization of the plastics and the resulting quality of the final products.

1. Plasticizing pressure:

(Back Pressure) When using a screw injection machine, the pressure that the melt at the top of the screw receives as the screw rotates and retreats is called plasticizing pressure, or back pressure.

The magnitude of this pressure can be adjusted by the overflow valve in the hydraulic system.

During injection, the plasticizing pressure needs to be adjusted according to the screw design, product quality requirements, and plastic types used.

If these conditions and the screw rotation speed remain constant, increasing the plasticizing pressure will strengthen the shear effect, which raises the melt temperature but reduces plasticizing efficiency, increases countercurrent and leakage flow, and increases driving power.

However, increasing the plasticizing pressure can also lead to uniform melt temperature, color mixture, and gas discharge.

In general operation, the plasticizing pressure should be as low as possible while ensuring good product quality.

The specific value varies based on the plastic type used, but it usually does not exceed 20 kg/cm2.

2. Injection pressure:

In modern production, the injection pressure of almost all injection machines is based on the pressure applied at the top of the plunger or screw pushing against the plastic, as converted from the oil circuit pressure.

The function of injection pressure in injection molding is to overcome the flow resistance of plastic from the barrel to the cavity, provide the melt with a filling rate, and compact the melt.

Forming cycle

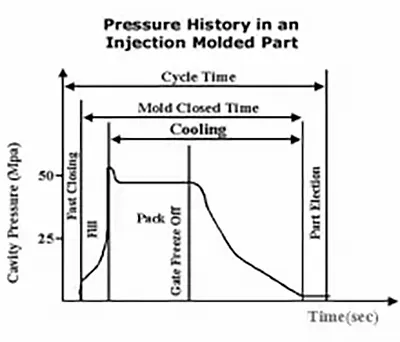

The duration needed to complete an injection molding process is referred to as the molding cycle, which is also known as the molding process. The molding cycle includes the following components:

Molding cycle: The molding cycle has a direct influence on labor productivity and equipment utilization. Hence, during the production process, the relevant time in the molding cycle should be reduced as much as possible while ensuring product quality.

Within the complete molding cycle, injection time and cooling time are the most crucial factors that significantly affect product quality.

The filling time in the injection process is inversely proportional to the filling rate and usually takes around 3-5 seconds during production.

The pressure holding time in the injection process refers to the time that the plastic material is kept under pressure in the mold cavity. It accounts for a significant portion of the injection time and typically lasts between 20-120 seconds (with thick parts potentially taking 5-10 minutes).

The pressure holding time affects the dimensional accuracy of the product before the material at the gate solidifies, but not afterward. The optimal pressure holding time depends on the material and mold temperatures, as well as the size of the main runner and gate.

If the dimensions and process conditions of the main runner and gate are normal, the pressure value with the smallest fluctuation range of the product’s shrinkage rate is usually chosen as the standard.

The cooling time primarily depends on the product’s thickness, plastic’s thermal and crystalline properties, and the mold temperature. The cooling time generally lasts between 30 and 120 seconds.

A long cooling time is unnecessary and can reduce production efficiency and make it challenging to demold complex products. Forced demolding can also lead to demolding stress.

The other times in the molding cycle are related to the degree of continuity and automation in the production process.

Parameter of Injection Molding

1. Injection pressure

The injection pressure is generated by the hydraulic system of the injection molding machine.

The pressure from the hydraulic cylinder is transmitted to the plastic melt through the machine’s screw.

Driven by the pressure, the plastic melt enters the mold through the nozzle of the injection molding machine and flows through the vertical runner (which also functions as the main runner for some molds), the main runner, and the shunt runner before reaching the mold cavity through the gate.

This process is known as the injection molding process or the filling process.

The pressure is necessary to overcome the resistance in the flow of the melt. Conversely, the pressure from the injection molding machine must offset the resistance in the flow process to ensure smooth filling.

Throughout the injection molding process, the pressure at the nozzle of the injection molding machine is the highest to overcome the melt’s flow resistance.

Afterward, the pressure gradually decreases along the flow length toward the front end of the melt.

If the mold cavity’s internal exhaust is adequate, the final pressure at the front end of the melt will be atmospheric pressure.

There are various factors that can impact the melt filling pressure, which can be broadly categorized into three groups:

- Material factors, such as plastic type, viscosity, and so on.

- Structural factors, which include the type, number, and positioning of the gating system, the shape of the mold cavity, and the thickness of the product.

- Elements related to the forming process.

2. Injection time

The term “injection time” refers to the duration needed for the plastic melt to fill the cavity, excluding auxiliary processes such as mold opening and closing.

Even though the injection time is brief and has a minimal impact on the molding cycle, adjusting the injection time has a significant effect on controlling the pressure of the gate, runner, and cavity.

A reasonable injection time is essential for achieving optimal melt filling, and it has a great impact on improving product surface quality and reducing dimensional tolerances.

The injection time is much shorter than the cooling time, usually about 1/10 to 1/15 of the cooling time. This principle can be used to forecast the total molding time of plastic components.

During mold flow analysis, the injection time shown in the analysis results is only equivalent to the injection time set in the process conditions when the screw rotation completely pushes the melt to fill the cavity.

If the pressure maintaining switch of the screw triggers before the cavity is fully filled, the analysis result will be greater than the process conditions’ setting.

3. Injection temperature

Injection temperature is a critical factor that affects injection pressure.

The barrel of an injection molding machine comprises 5-6 heating sections, and each raw material has its specific processing temperature (detailed processing temperature information is available from the material supplier).

The injection temperature must be controlled within a specific range.

If the temperature is too low, plasticization of the melt is poor, which affects the quality of molded parts and increases process difficulty.

If the temperature is too high, raw materials are prone to decomposition.

In the actual injection molding process, the injection temperature is often higher than the barrel temperature, and the higher value is related to the injection rate and material performance, up to 30 ℃.

This is because the molten material’s shear generates significant heat when it passes through the injection port.

There are two ways to compensate for this difference in mold flow analysis. One method is to attempt to measure the melt temperature during air injection, while the other is to include the nozzle in the modeling.

4. Pressure maintaining pressure and time

At the end of the injection molding process, the screw stops rotating and moves forward, and the injection molding enters the pressure holding stage.

During the pressure holding process, the injection molding machine’s nozzle continuously feeds the cavity to fill the volume left by the part’s shrinkage.

If pressure is not maintained after the cavity is filled, the part will shrink by approximately 25%, resulting in shrinkage marks, particularly on the ribs, due to excessive shrinkage.

The pressure holding pressure is typically around 85% of the maximum filling pressure, although it should be determined based on the specific circumstances.

5. Back pressure

Back pressure refers to the resistance encountered by the screw when it reverses and retracts to store materials.

Using high back pressure can help disperse colorants and melt plastics, but it also prolongs screw retraction time, reduces plastic fiber length, and increases injection molding machine pressure.

Therefore, back pressure should be kept low, usually no more than 20% of the injection molding pressure.

When injecting foam plastic, back pressure should be higher than the pressure formed by the gas; otherwise, the screw may be pushed out of the barrel.

Some injection molding machines can program back pressure to compensate for the reduction in screw length during melting, which reduces input heat and temperature.

However, estimating the result of this change can be challenging, making it difficult to adjust the machine accordingly.

Defect Resolution of Injection Molding

The injection molding process is a complex process that involves various factors, such as mold design, mold manufacturing, raw material characteristics, raw material pretreatment methods, molding process, injection molding machine operation, and processing environment conditions. It is also closely related to the product cooling time and post-processing process.

Therefore, the quality of the product is not solely determined by the injection precision and measurement precision of the injection molding machine or only by the quality of mold design and the precision level of mold processing. It is generally affected and restricted by other factors.

Given the constraints of these complex factors, defects in injection molded products are inevitable. Therefore, it is crucial to explore the internal mechanism of defects and predict potential defect positions and types in products. This can guide mold design and improvement, summarize defect generation rules, and establish more reasonable process operating conditions.

We will explain the mechanism and solutions for injection molding defects based on three main factors that affect the plastic material characteristics, mold structure, injection molding process, and injection molding equipment in the injection molding process.

Classification of common defects of injection molded products

The plastic raw materials used in the injection molding process are varied, and the mold design types and forms are also diverse. Additionally, operator familiarity with specific injection molding machines, worker operating skills and practical experience, and the objective environment (such as ambient temperature, humidity, and air cleanliness) may all vary with the seasons.

These objective and subjective conditions collectively determine the occurrence of defects in injection molded products.

In general, there are three aspects that are used to evaluate the performance of plastic products. These are:

- Appearance quality, which includes integrity, color, and luster.

- Accuracy between size and relative position, which refers to size accuracy and position accuracy.

- Mechanical, chemical, and electrical properties that correspond to the product’s use, known as functionality.

Therefore, any problem in any of these three aspects could lead to the production and expansion of product defects.

Common defects of injection-molded products can be classified into the following categories:

- Appearance defects, such as craze, discoloration, and weld marks.

- Process problems, including flash, shrinkage, and lack of glue.

- Performance problems, such as warpage and embrittlement.