To perform thread milling, the machine tool must have the capability for three-axis linkage.

CNC machines have the capability for spiral interpolation, which is controlled by the machine tool to produce the spiral path.

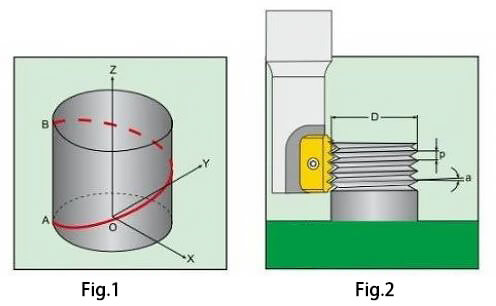

Spiral interpolation is created by the combination of plane arc interpolation and linear motion perpendicular to the plane.

For example, the spiral path from point A to point B (as shown in Figure 1) is produced by combining the X-Y plane arc interpolation motion with the linear Z axis motion.

Most CNC systems can achieve this function using two different commands:

- G02: Instantaneous clockwise arc interpolation command

- G03: Counterclockwise arc interpolation command

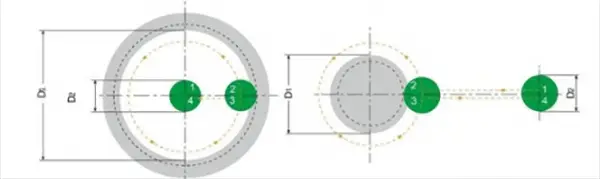

The display of thread milling motion (as shown in Figure 2) is produced by the rotation of the tool and the spiral interpolation motion of the machine tool.

During the egger circle interpolation process, the shape of the tool is used to process the required thread by combining the movement of the tool moving along the z-axis direction with the egger pitch.

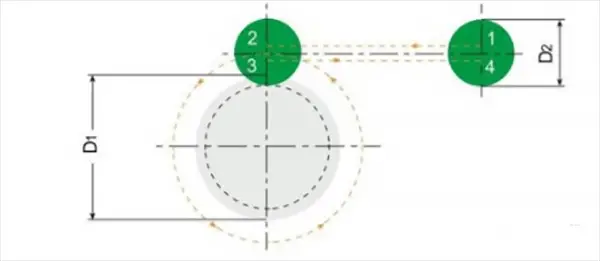

There are three cutting methods that can be used for thread milling: arc cutting method, radial cutting method, and tangential cutting method.

1. Arc cutting method

With this method, the cutting tool cuts smoothly, resulting in no visible cutting marks and reducing vibrations even when machining hard materials.

However, the programming of this method is more complex compared to the radial cutting method.

It is recommended to use this method when producing precise threads.

- 1-2: fast positioning;

- 2-3: the cutter cuts in tangentially along the arc feed, and interpolates the feed along the Z axis at the same time;

- 3-4: 360 ° full circle thread interpolation movement, axial movement of a lead;

- 4-5: the cutter cuts in tangentially along the arc feed, and performs interpolation movement along the Z axis at the same time;

- 5-6: quick return.

2. Radial cutting method

This method is the simplest, but there may be two situations that arise:

- Small vertical marks may be left at the start and end points of the cut, but this will not affect the quality of the thread.

- When machining very hard materials, if the cutting is close to the full tooth shape, the increased contact area between the tool and the workpiece may cause tool vibration.

To avoid vibration during close-to-full-tooth cuts, it is recommended to reduce the feed rate to 1/3 of the spiral interpolation feed rate as much as possible.

- 1-2: fast positioning;

- 2-3: the whole circle of 360 ° performs spiral interpolation movement and moves axially by one lead;

- 3-4: radial return.

3. Tangential cutting method

This method is straightforward and has the benefits of the arc cutting method, but it is only suitable for milling external threads.

- 1-2: fast positioning;

- 2-3:360 ° full circle makes thread interpolation movement, and the axial movement is one lead;

- 3-4: quick return.