Why do laser welds sometimes develop pores, compromising their integrity? This article explores the causes behind these tiny cavities and offers practical methods to prevent them. By understanding how factors like laser power, welding speed, and gas dynamics influence pore formation, you can optimize your welding process for stronger, defect-free results. Dive in to learn actionable strategies that will enhance the quality and reliability of your laser welds.

Laser welding is widely utilized in numerous industries for its advantages of concentrated energy, high precision, and excellent results.

However, the use of laser welding machines also brings about potential uncertainties.

Improper operation or imperfect processes during laser welding can often result in porosity in the weld.

To address this issue, it is important to first identify the causes of porosity and then provide appropriate solutions based on the root cause analysis.

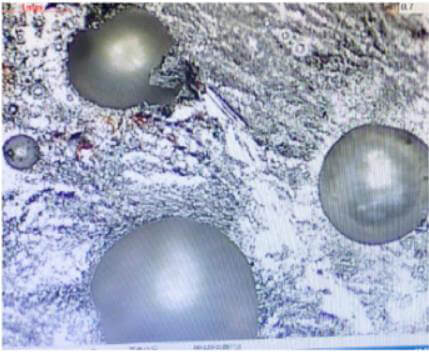

Porosity in laser welding is caused by the entrapment of gas during the solidification process of the weld metal. The cooling rate of the weld metal in laser welding is significantly faster compared to conventional welding, making it difficult for gas to escape and leading to the formation of pores.

There are two main causes of porosity in laser welding:

Weld formation process

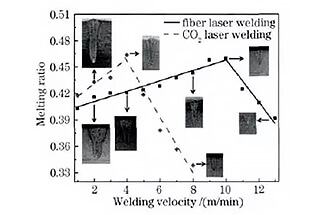

There is a correlation between the number of pores in a weld and the size of the laser power used. An increase in laser power is associated with an increase in the number of pores.

It is believed that the high heat generated by increased laser power causes the molten metal to reach extremely high temperatures, resulting in metal vapor production, making the liquid metal in the molten pool unstable, and causing turbulence.

To reduce the formation of pores, it is recommended to lower the laser power and increase the welding speed. This will reduce the production of metal vapor and minimize the formation of pores.

The principle of metallurgy is utilized to minimize the formation of pores by introducing an active gas that dissolves in the weld or reacts with the molten metal to form compounds. Pulse laser welding is also employed to alter the behavior of small holes and reduce the influx of shielding gas.

While these methods can help reduce the number of pores, they cannot completely eliminate them. The beam swing method is used to minimize or eliminate pores in deep penetration laser welding.

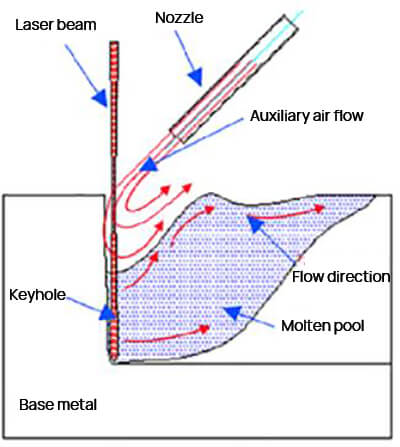

The reciprocating movement of the beam over the weld prolongs the residence time of liquid metal in the welding pool and increases the heat input per unit area, reducing the depth-to-width ratio of the weld. This promotes bubble formation and helps eliminate pores. Additionally, the oscillation of the beam flow stirs the welding pool, increasing convection and helping to eliminate pores.

By using a surface cleanliness meter and an RFU unit, the cleanliness of parts can be quickly and accurately assessed. This data helps to avoid the impact of human subjectivity in the cleaning process and optimize it for greater efficiency, reducing rework and production costs.