Ever wondered why welding electrodes sometimes stick? This common issue can disrupt your work and damage materials. In this article, you’ll discover the main reasons for electrode sticking, such as misaligned surfaces, rough electrode tips, insufficient pressure, and cooling issues. By understanding these factors, you’ll learn practical solutions to prevent electrode sticking and ensure smoother welding operations. Get ready to enhance your welding skills and avoid frustrating interruptions!

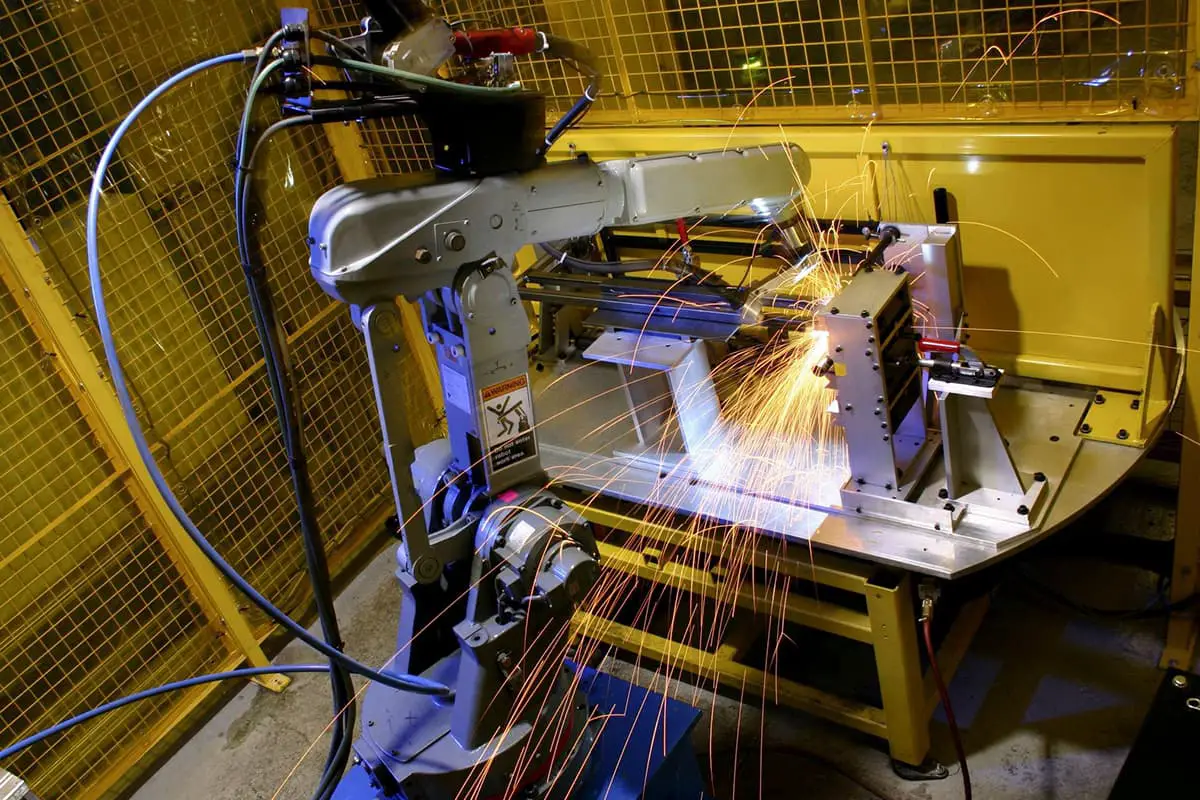

Adhesive electrode refers to an abnormal welding between the electrode and the part, causing the electrode to adhere to the part. This can lead to the electrode being pulled out or the part rusting, particularly if the cooling water flow is disrupted.

There are four primary causes of electrode sticking during welding: misalignment of the working surfaces of the two electrodes, roughness on the working surfaces of the electrodes, insufficient electrode pressure, and improper connection or blockage of the cooling water circulation in the outlet of the welding gun.

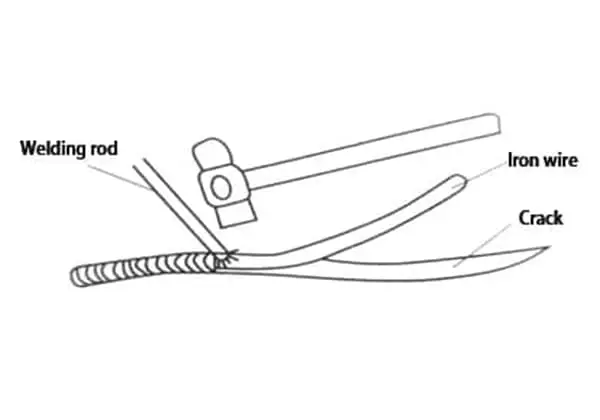

If the working surfaces of the two electrodes are not parallel, it can result in localized contact between the electrode working surfaces and the parts. This increases the contact resistance between the electrodes and the parts, and decreases the current flow in the welding circuit.

Related reading: Wire Feeding Speed and Welding Current

When the current is concentrated at a localized contact point, and the current density at that point is higher than the normal current density of the electrode working surface, the temperature of that point will increase and reach the welding temperature of both the electrode and the part. This results in the fusion of the electrode and the part.

If the working surface of the electrode does not properly align with the part, and only makes contact with certain protrusions, it will result in misalignment between the two electrode working surfaces. This can cause electrode sticking.

The contact resistance is inversely proportional to the pressure. If the electrode pressure is insufficient, the contact resistance between the electrode and the part will increase. The increased resistance heat at the point of contact will raise the temperature of the contact surface between the electrode and the part to the welding temperature, resulting in a fusion connection between the electrode and the part.

If the water pipe at the cooling outlet of the welding gun is improperly connected or the cooling water circulation is blocked, the electrode temperature will increase, potentially causing a fusion connection between the electrode and the part during continuous spot welding.

The four conditions mentioned above are potential causes of the fusion connection between the electrode and the part, leading to electrode sticking.

To prevent electrode sticking, it is important to take steps to avoid these conditions.

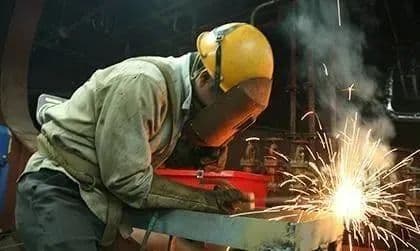

(1) To avoid electrode sticking, the working surfaces of the two electrodes should be made parallel and free from rough defects by filing the electrode head. The welding program can be set to the grinding program (with no current output), and the two electrode working surfaces can be checked for parallel alignment using an empty welding gun.

(2) In the grinding state, the welding should be air punched 5 to 10 times to forge the working surfaces of the two electrodes, increasing the contact area within the specified electrode tip diameter range and improving the surface hardness.

(3) The working surface of the electrode can be heated with an oxyacetylene flame to form an oxide layer (oxide buildup), which improves the melting point of the electrode working surface and reduces its weldability to the part.

(4) The electrode working surface can be coated with red lead, as configured by the welder, to decrease its weldability to the part.

(5) The electrode pressure should be adjusted, and high pressure, high power, and short power-on time welding parameters should be used.

(6) The cooling water pipe should be cleaned regularly to ensure proper cooling water flow.

These measures can help solve the issue of electrode sticking during welding.