Have you ever faced challenges with bending stainless steel plates? This article unravels the complexities of stainless steel bending, from the force required to the impact of spring back. Learn the key techniques and tips to master this essential metalworking process!

Due to its high yield strength, hardness, and prominent cold-working effect, stainless steel plate bending has the following characteristics:

According to the above characteristics, generally speaking:

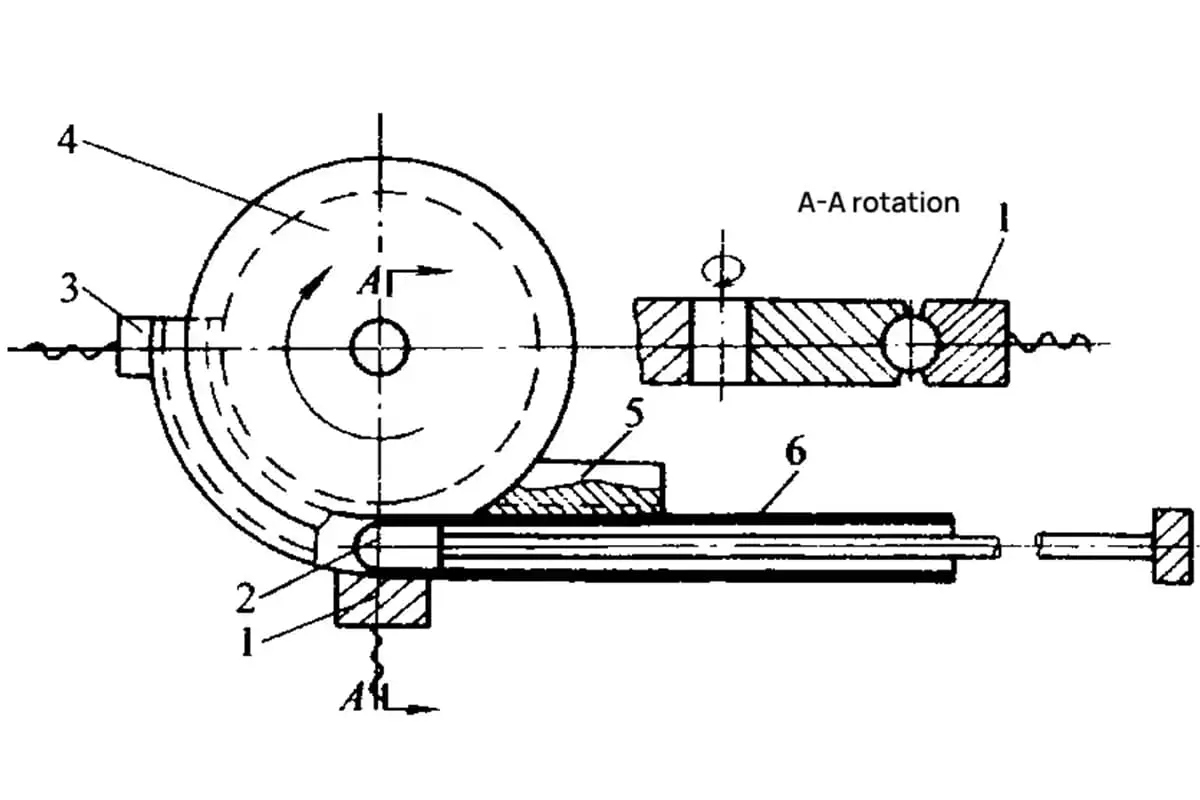

Under the same unit size, the thicker the plate, the more bending force is required. The bending force increases as the plate thickness increases.

Under the same unit size, the higher the tensile strength, the lower the elongation rate, the more bending force required, and the larger the bend angle should be.

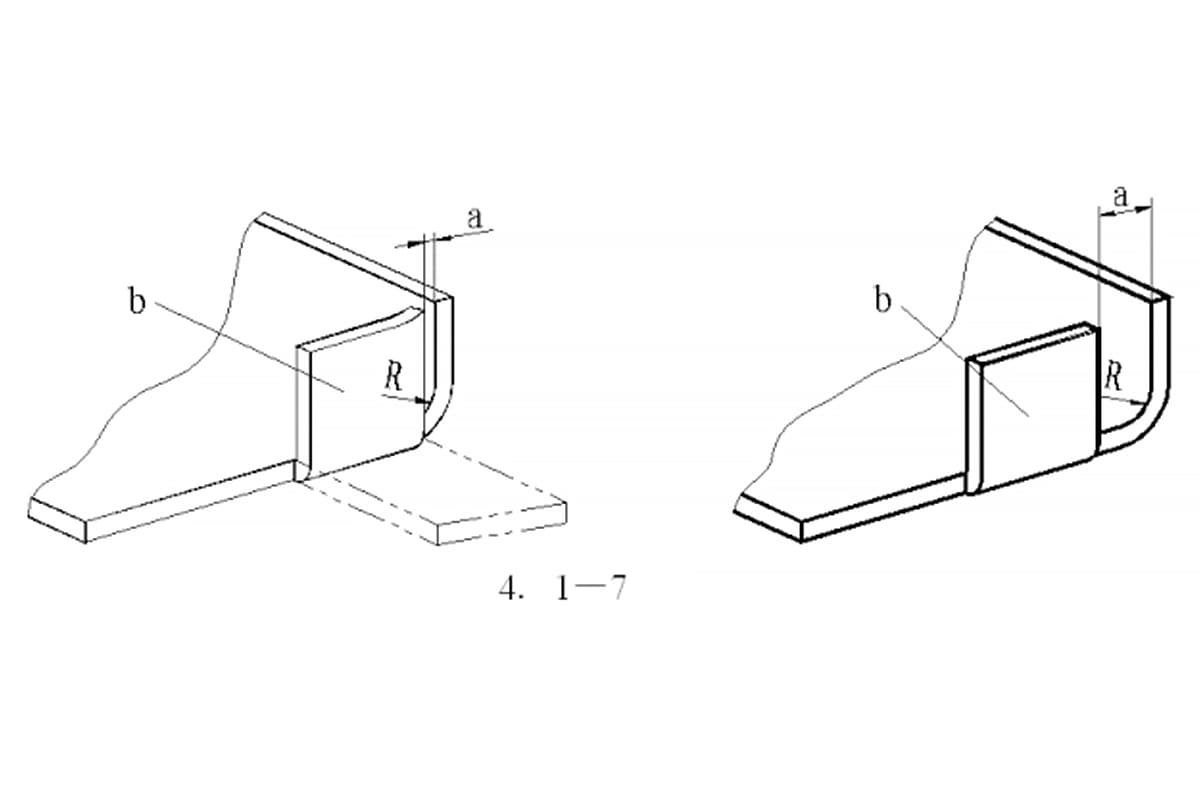

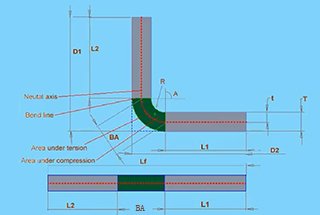

When designing the plate thickness in relation to the bending radius, according to experience, the unfolded size of the workpiece with one bend should be calculated by adding the two right-angle sides and then subtracting two thicknesses. This will fully meet the design accuracy requirement. Using an empirical formula to calculate the quantity can simplify the calculation process and greatly improve production efficiency.

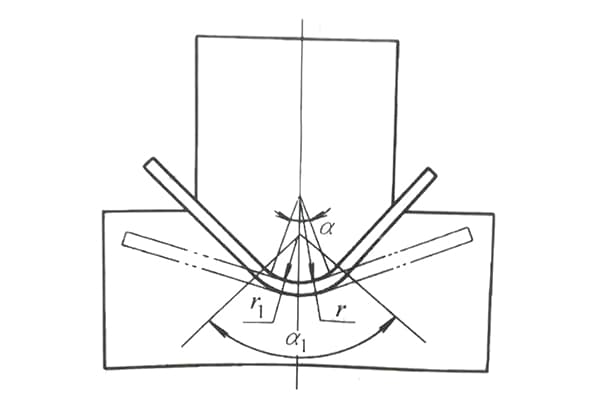

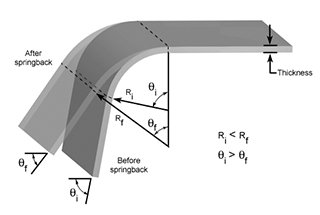

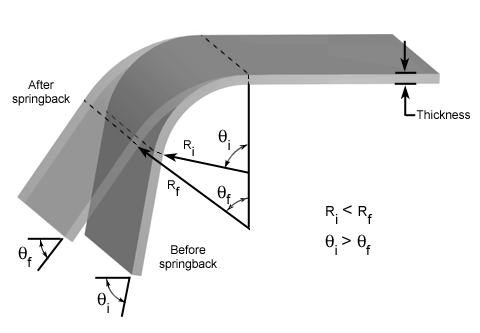

The higher the yield strength of the material, the greater the spring back. Therefore, the angle of the punch die for the 90-degree bend part should be smaller.

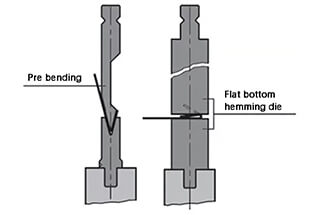

Compared to carbon steel, for the same thickness of stainless steel, the bending angle is larger. It is important to pay special attention to this point, as bending cracks can appear, affecting the strength of the workpiece.

The return of stainless steel is indeed problematic, and it is due to several reasons:

To mitigate these issues, I have a habit of revising the mold after each test and making changes as needed, taking into account both angle rebound and radius rebound. Of course, a skilled technician can make adjustments efficiently, and they will inform the designer of the necessary changes.

I usually try to move 5 pieces at a time, and the efficiency depends largely on the technician’s skill and experience.