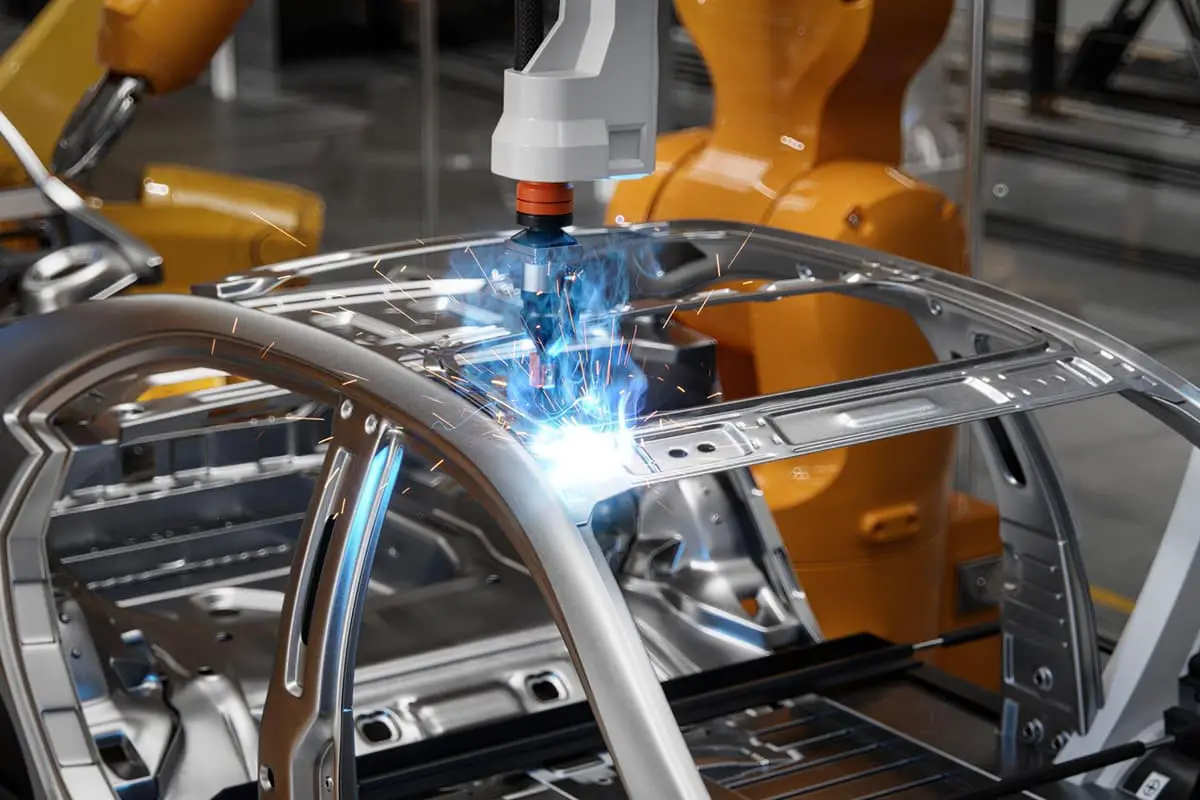

Have you ever wondered how to effectively weld different types of stainless steel? This article dives into the specialized welding methods for martensitic and duplex stainless steel, detailing the challenges and solutions specific to each type. By exploring preheating techniques, material selection, and post-weld treatments, you’ll learn how to achieve strong, durable welds while minimizing risks like cold cracking and embrittlement. This guide provides crucial insights for anyone looking to master the nuances of welding these complex materials.

This refers to a type of stainless steel with a martensitic microstructure at room temperature and whose mechanical properties can be modified through heat treatment.

As a general description, it is a type of stainless steel that can be hardened.

Some common grades of martensitic stainless steel include 1Cr13, 2Cr13, 3Cr13, 4Cr13, 3Cr13Mo, 1Cr17Ni2, 2Cr13Ni2, 9Cr18, and 9Cr18MoV.

Related reading: Stainless Steel Grades

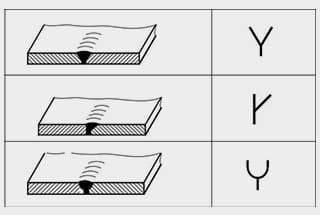

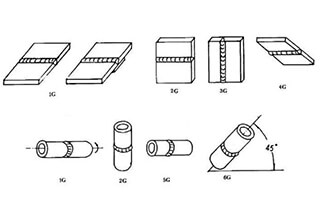

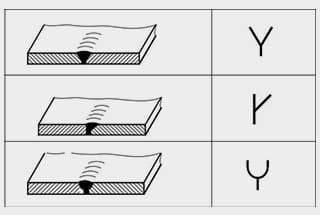

Martensitic stainless steel can be welded using various electric arc welding techniques.

Currently, rod arc welding remains the primary method, while the use of carbon dioxide gas shielded welding or argon-carbon dioxide mixed gas shielded welding can significantly reduce the amount of hydrogen in the weld, thus reducing the risk of cold cracking in the weld.

Generally, when higher strength is required in the weld, Cr13 martensitic stainless steel welding rods and wires are utilized to make the chemical composition of the weld metal similar to that of the base metal, but this increases the likelihood of cold cracking.

Considerations:

a. Preheating is necessary prior to welding and the temperature should not exceed 450°C to prevent embrittlement at 475°C.

A post-welding heat treatment must be performed.

Once the temperature has cooled to 150-200°C, a post-welding heat treatment should be carried out for 2 hours to allow for the transformation of all parts of the austenite into martensite, followed by high temperature tempering where the temperature is raised to 730-790°C.

The holding time should be 10 minutes per 1mm of plate thickness, but not less than 2 hours, and finally it should be air cooled.

b. To prevent cracking, the content of S and P in the welding rods and wires should be less than 0.015%, and the Si content should not be greater than 0.3%.

An increase in Si content can cause the formation of coarse primary ferrite, which decreases the plasticity of the joint.

The carbon content should typically be lower than that of the base metal, which can reduce its hardenability.

The weld metal of Cr Ni austenitic steel has a high level of plasticity, which can alleviate the stress produced during the martensitic transformation in the heat-affected zone.

Additionally, the Cr Ni austenitic stainless steel type welds have a high solubility for hydrogen, which can decrease the diffusion of hydrogen from the weld metal to the heat-affected zone and effectively prevent cold cracks, thus preheating is not necessary.

However, the strength of the weld is relatively low and cannot be enhanced through post-weld heat treatment.

Martensitic stainless steel has a high chromium content, which significantly increases its ability to be hardened.

Regardless of its initial state before welding, welding always results in the formation of martensite near the seam.

As the hardening tendency increases, the joint becomes more prone to cold cracking, especially when there is hydrogen present. In such conditions, martensitic stainless steel is also prone to the formation of hazardous hydrogen-induced delayed cracking.

Measures:

Martensitic stainless steels, particularly those with higher levels of ferrite-forming elements, have a higher tendency for grain growth.

A slow cooling rate can lead to the formation of coarse ferrite and carbide in the welding heat-affected zone (HAZ), whereas a rapid cooling rate can cause hardening and the formation of coarse martensite in the HAZ.

These coarse structures reduce the plasticity and toughness of the HAZ of martensitic stainless steel, making it brittle.

Countermeasures:

Preheating prior to welding is a crucial technique to prevent cold cracks.

For carbon content between 0.1% to 0.2%, the preheating temperature should be between 200 to 260°C, while a high-strength weldment can be preheated to a temperature between 400 to 450°C.

The weldment should not be directly heated from the welding temperature for tempering treatment because the austenite may not be fully transformed during welding.

Immediate heating and tempering after welding can cause carbides to precipitate along the austenite grain boundary, resulting in the transformation of austenite into pearlite and a coarse grain structure, which significantly reduces toughness.

Therefore, the weldment must be cooled before tempering and the austenite in the weld and heat-affected zone must be largely decomposed.

For low-strength weldments, they can be cooled to room temperature and then tempered.

For thick weldments, a more complex process is required. After welding, it should be cooled to 100-150°C, kept warm for 0.5-1 hour, and then heated to the tempering temperature.

The purpose of post-weld heat treatment is to lower the hardness of the weld and heat-affected zone, enhance its plasticity and toughness, and decrease welding residual stress.

Post-weld heat treatment can include tempering and full annealing. The tempering temperature should be between 650-750°C, with a holding time of 1 hour followed by air cooling.

If the weldment requires machining after welding, full annealing can be performed to achieve minimum hardness.

The annealing temperature should be between 830-880°C, with a holding time of 2 hours followed by furnace cooling to 595°C and then air cooling.

Electrodes for welding martensitic stainless steel are classified into two categories: chromium stainless steel electrodes and chromium nickel austenitic stainless steel electrodes.

Common chromium stainless steel electrodes include E1-13-16 (G202) and E1-13-15 (G207).

Common chromium nickel austenitic stainless steel electrodes include E0-19-10-16 (A102), E0-19-10-15 (A107), E0-18-12Mo2-16 (A202), and E0-18-12Mo2-15 (A207), among others.

Duplex stainless steel has both the advantages and disadvantages of austenitic and ferritic steel, and reduces their respective weaknesses.

(1) The risk of hot cracking is much lower compared to austenitic steel.

(2) The risk of cold cracking is significantly lower compared to ordinary low alloy high strength steel.

(3) After cooling in the heat-affected zone, a higher amount of ferrite is retained, increasing the risk of corrosion and hydrogen-induced cracking (embrittlement).

(4) The welded joint of duplex stainless steel is prone to the precipitation of δ phase, an intermetallic compound of Cr and Fe.

Its formation temperature ranges from 600°C to 1000°C and can vary based on the specific steel grade.

Table 1 Temperature Range of Solution Treatment, Phase δ and 475 ℃ Brittleness of Duplex Stainless Steel

| Content | 2205 dual phase steel and 2507, etc | Super duplex steel 00Cr25Ni7Mo3CuN |

| Solid solution temperature/℃ | 1040 | 1025~1100 |

| Peeling temperature when heated in air/℃ | 1000 | 1000 |

| Phase δ formation temperature/℃ | 600~1000 | 600~1000 |

| 475 ° C embrittlement temperature/℃ | 300~525 | 300~525 |

The welding process for duplex stainless steel involves TIG welding first, followed by electrode arc welding.

When using submerged arc welding, the heat input and interpass temperature must be closely monitored and excessive dilution must be avoided.

Note:

When TIG welding is used, 1-2% nitrogen should be added to the shielding gas (adding more than 2% nitrogen may increase porosity and cause instability in the arc). The addition of nitrogen helps absorb nitrogen from the weld metal, preventing nitrogen loss through diffusion in the weld surface area, and contributes to stabilizing the austenite phase in the welded joint.

Welding materials with higher levels of austenite-forming elements (such as Ni, N) are chosen to encourage the transformation of ferrite in the weld into austenite.

The 22.8.3L electrode or welding wire is commonly used for welding 2205 steel, while the 25.10.4L electrode or 25.10.4R electrode is frequently used for welding 2507 steel.

Table 2 Welding materials and FN of Typical duplex stainless steel

| Base metal | Welding Material | Chemical composition | Name | FN(%) | ||||||||

| C | Si | Mn | Cr | Ni | Mo | N | Cu | W | ||||

| 2507 | Welding wire | 0.02 | 0.3 | 0.5 | 25 | 10 | 4 | 0.25 | – | – | 2507/P100 | 40~100 |

| 0.02 | 25 | 10 | 4 | 0.25 | – | – | Sandivick 25.10.4L | |||||

| Welding core | 0.03 | 0.5 | 1 | 25 | 9.5 | 3.6 | 0.22 | – | – | Avesta 2507/p100 | ||

| 0.04 | 25 | 10.5 | 4 | 0.25 | – | – | Sandivick 25.10.4L | |||||

| Zeron100 | Welding wireWelding core | 0.04 | 1.2 | 2.5 | 25 | 10 | 4 | 0.22 | 1 | 1 | 22.9.4CuWL 22.9.4CuWLB | 40~60 |

| 2205 | Welding wire | 0.02 | 0.5 | 1.6 | 22.5 | 8 | 3 | 0.14 | – | – | Sandivick 22.8.3L | 40~60 |

| Welding core | 0.03 | 1.0 | 0.8 | 22.5 | 9.5 | 3 | 0.14 | – | – | Sandivick 22.8.3R | ||

(1) During the welding process, the control of welding energy, interpass temperature, preheating, and material thickness will affect the cooling rate and subsequently affect the structure and properties of the weld and heat-affected zone.

To achieve optimal weld metal properties, it is recommended to control the maximum interpass temperature at 100°C. If post-weld heat treatment is necessary, the interpass temperature restrictions may be lifted.

(2) It is preferred to avoid post-weld heat treatment for duplex stainless steel.

If post-weld heat treatment is necessary, water quenching is the method used. During heat treatment, the heating should be rapid, and the holding time at the heat treatment temperature should be between 5-30 minutes, sufficient to restore the phase balance.

Oxidation of metal is a concern during heat treatment, so the use of an inert gas for protection should be considered.