Tungsten argon arc welding (TIG) is widely used in modern welding methods because of its high welding joint quality, good formability, excellent welding performance and flexible application scenarios, and it can be portable used in complex environments.

However, its limitations are also very obvious.

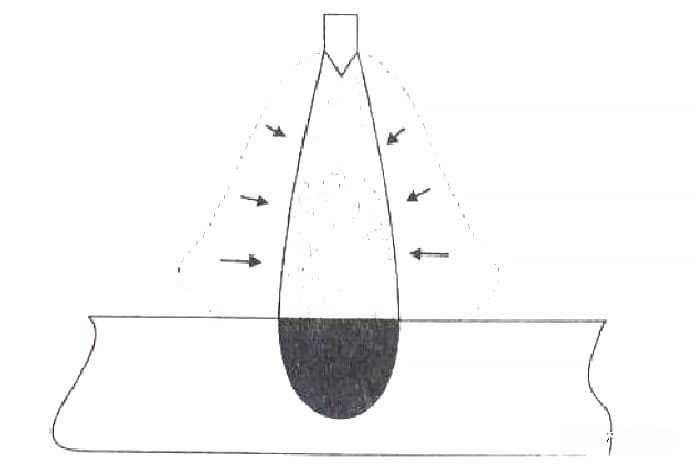

No matter carbon steel, stainless steel or titanium materials, ordinary TIG welding is only applicable to thin plates, which is determined by its welding principle: during TIG welding, due to the temperature coefficient and surface tension, the flow direction of the welding pool is also export-oriented, as shown in Fig. 1.

Therefore, when the welding power is increased, the width of the welding pool is increased more, but the depth is increased less.

At the same time, the bearing capacity of the tungsten electrode is limited, the arc heat is relatively dispersed during the welding process, and the power of the arc is limited.

Therefore, in general, the TIG welding speed is low, and the penetration depth of the weld is shallow. Generally, only thin plates below 3mm can be welded;

Generally, the plate or pipe with thickness greater than 3mm needs to be beveled first, and backing welding + cover welding is adopted, which is time-consuming, complicated and costly.

Its disadvantages can be summarized as follows: the penetration depth of single-layer weld is shallow, the process of multi-layer weld is complex and the cost is high.

Fig. 1 flow direction of TIG welding pool

With the development of welding technology, in order to overcome the limitation of TIG welding penetration, active argon arc welding (A-TIG) came into being.

The A-TIG welding method was first proposed by the Ukrainian Barton Welding Research Institute (PWI) in the 1960s, but it was not until the late 1990s that extensive research was carried out in research institutes in European and American countries (such as EWI and TWI).

Among them, the active flux developed by EWI has been widely used. However, the application in this field has not been popularized in China.

In terms of welding method, the only difference between A-TIG welding and conventional TIG welding is that a process of coating active agent is added.

That is, before welding, the welding active agent is uniformly coated on the weld surface, as shown in Fig. 2, which is the coating effect of welding active agent prepared by the small team.

However, for thick plate welding, the process of beveling is omitted, which greatly improves the production efficiency and production cost.

Under the same welding specification, compared with TIG, the weld penetration can be greatly improved (up to 300%), as shown in Fig. 3 (a) below is the traditional TIG welding pool, (b) is the A-TIG pool under the same welding parameters.

At present, A-TIG welding method has been used to weld stainless steel, carbon steel, nickel base alloy and titanium alloy.

Compared with conventional TIG, A-TIG can greatly improve productivity, reduce production cost and reduce welding deformation.

It has a wide application prospect.

Fig. 2 Effect of coating active agent on welds

Fig. 3 Comparison of welding penetration

The penetration increasing mechanism of A-TIG welding includes the viewpoint of “arc contraction”, “surface tension”, “anode spot contraction” and “plasma contraction”.

Ukrainian scholars tend to the view of “arc contraction”, while American scholars believe that the view of “surface tension” is the main reason for the increase of penetration depth.

At present, there is no unified view on the mechanism of weld penetration increase in the world.

Although the arc shrinkage is obvious, there is still no consensus mechanism to explain the effect of active flux elements on welding penetration in A-TIG welding.

Now it is believed that the most likely mechanism will be related to the influence of halogens and oxides at the arc root and plasma region (also related to voltage), rather than the influence of molten pool movement.

As shown in Fig. 4 below, the number of electrons in the peripheral area of the arc decreases, and electrons are the main carrier of charge.

This forces the arc to contract and reach a new equilibrium state, which has a higher current density in the arc column region and the anode region.

This reaction is thought to occur mainly in the peripheral region of the arc at lower temperature, which leads to the reduction of the arc column diameter and anode area.

Fig. 4 Schematic diagram of arc contraction

The viewpoint of “surface tension” holds that the metal flow state in the molten pool plays a decisive role in the formed penetration depth.

In traditional TIG welding, the surface tension of the molten metal in the molten state forms a surface tension flow from the center of the molten pool to the periphery of the molten pool due to the temperature coefficient, and the resulting penetration depth is relatively shallow;

When the active agent is present in the molten pool metal, the surface tension gradient of the liquid metal in the molten pool changes, so that the molten pool metal forms a flow direction from the periphery of the molten pool to the center of the molten pool, and the heating efficiency of the bottom molten pool is improved, thereby forming a larger molten depth.

As shown in Fig. 5 below.

Fig. 5 Effect of surface tension on molten pool flow

According to the viewpoint of “anode spot”, after adding sulfide, chloride and oxide to the molten pool, the anode spot of the molten pool will shrink obviously, as shown in Fig. 6, and a large penetration depth will be generated.

For this phenomenon, the research shows that: after adding the active agent, the metal vapor generated by the molten pool is suppressed.

Because the metal particles are more likely to be ionized, when the metal vapor is reduced, only a small range of anode spots can be formed, and the arc conductive channel is constricted.

While the electromagnetic convection inside the molten pool is activated, the plasma convection on the surface of the molten pool is weakened, so as to form a larger penetration depth.

This explanation is more convincing for non-metallic compound type active agents, but not for metal compounds.

Fig. 6 Arc anode spot area shrinkage in the presence of active elements

In recent years, a large number of welding researchers at home and abroad have used various auxiliary methods to study the application of A-TIG in the welding of medium and thick plates.

It has been found that different effects of active agents can be obtained through the proportion of different components in the active agents, which have different effects on the increase of weld penetration and the quality of the weld.

For specific materials, they can be developed and applied to industrial production by adjusting the ratio of active elements or adding other trace active elements to form active agents.

It is also hoped that this technology can be more widely used.

As the founder of MachineMFG, I have dedicated over a decade of my career to the metalworking industry. My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for metals. I am constantly thinking, reading, and writing about these subjects, constantly striving to stay at the forefront of my field. Let my knowledge and expertise be an asset to your business.