Have you ever wondered how the steel in your car or the pipes in your home are made? This article dives into the fascinating world of forging and rolling, two essential metal processing techniques. Learn the key differences, advantages, and which method suits your needs best.

Forging and rolling are two of the most common metal processing techniques used in the manufacturing industry. Both methods involve applying pressure to metal to create a desired shape, but each has its own unique advantages and disadvantages.

In this article, we explore the differences between forging and rolling, including the types of each technique, their respective advantages and disadvantages, and the impact on the mechanical properties of the final product.

We also delve into the various types of forging and rolling, such as longitudinal, cross, and skew rolling, as well as free forging, die forging, and flashless die forging.

Whether you’re a seasoned industry professional or simply curious about the manufacturing process, this article provides a comprehensive overview of forging and rolling, including the factors that determine which method is best for a particular application.

So, whether you’re looking to improve the quality of your steel products, optimize your manufacturing process, or simply expand your knowledge of the industry, read on to discover the differences between forging and rolling and how they can impact your bottom line.

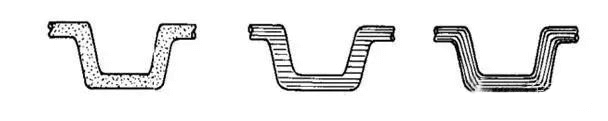

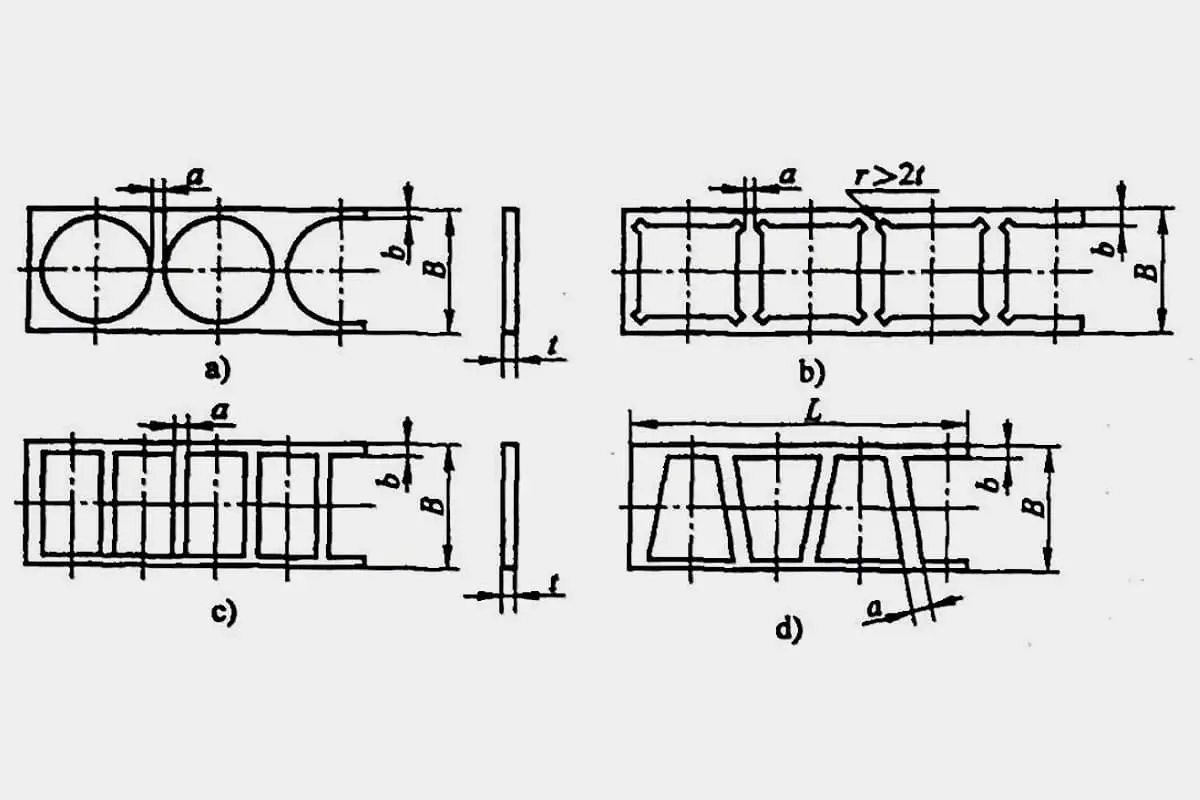

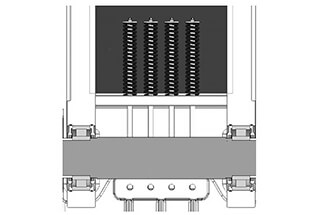

A pressure processing method in which a metal blank is passed through the gap between a pair of rotating rolls with various shapes, causing the cross-section of the material to decrease and its length to increase as a result of the compression from the rolls. This method is the most commonly used production technique for steel and is mainly used to produce profiles, plates, and tubes.

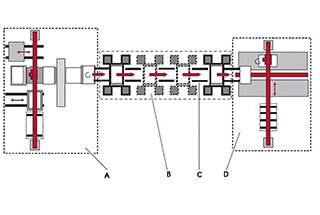

According to the movement of rolled parts, rolling can be divided into longitudinal rolling, cross- rolling and skew rolling.

Longitudinal rolling

The longitudinal rolling process is a process in which metal passes between two rolls that rotate in opposite directions and produces plastic deformation between them.

Cross-rolling

The movement direction of the rolled piece after deformation is consistent with the roll axis direction.

Skew rolling

The rolling piece moves in a spiral, the rolling piece and the roll axis are not with a special angle.

The rolling process can improve the quality of steel by destroying the casting structure of the steel ingot, refining the grain of the steel, and eliminating microstructural defects. This leads to a denser steel structure and improved mechanical properties, particularly in the rolling direction.

Additionally, high temperature and pressure during rolling can weld together any bubbles, cracks, or looseness that may have formed during casting.

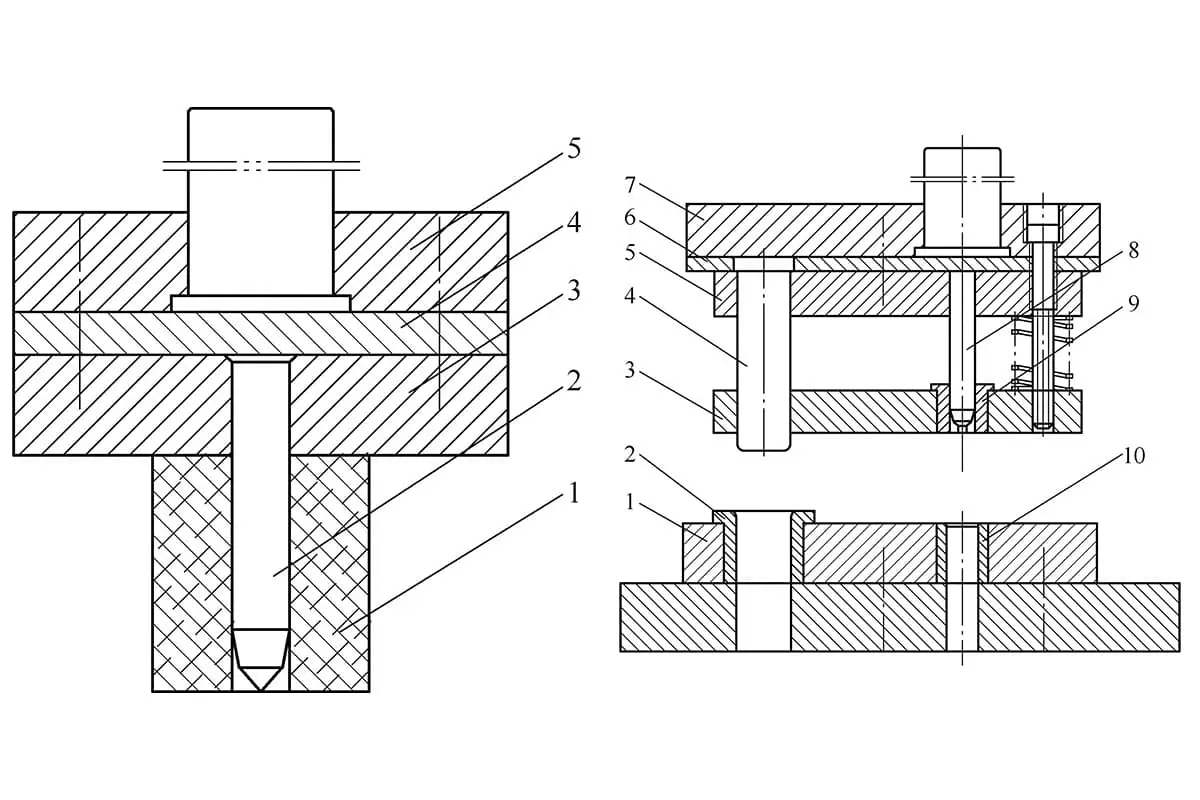

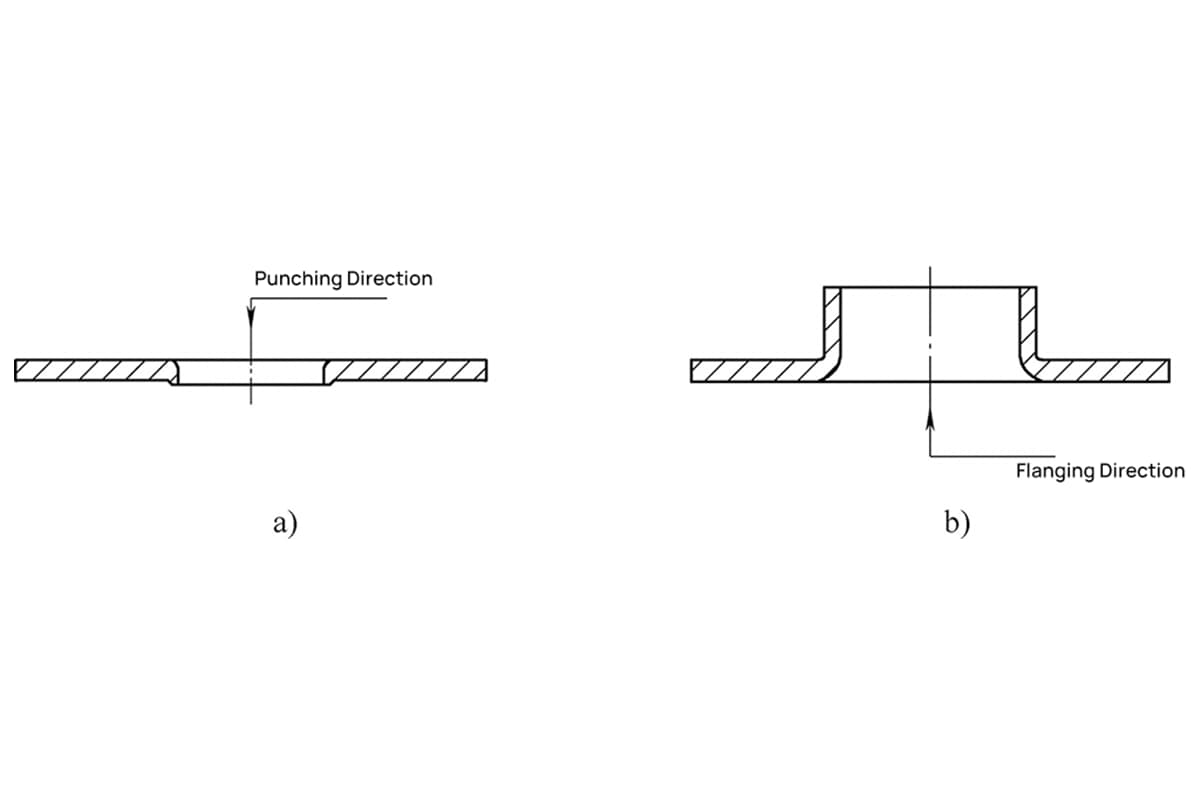

Forging is a processing method that utilizes forging and pressing machinery to apply pressure to metal billets, resulting in plastic deformation and the creation of forgings with specific mechanical properties and shapes.

This process eliminates casting defects and optimizes the microstructure of the metal during the smelting process. The preserved integrity of the metal flow lines leads to better mechanical properties in forgings compared to castings made of the same material.

Forgings are commonly used for important parts with high load and harsh operating conditions, as well as for simple shapes that can also be created from rolled plate, profile, or welded parts.

Forging can be divided into three categories: free forging, die forging, and flashless die forging.

Compared to castings, forging can improve the structure and mechanical properties of metal. During the forging process, hot working deforms and recrystallizes the casting structure, causing coarse dendrites and columnar grains to transform into a finer and more uniform equiaxed recrystallized structure.

The forging process also compacts and welds impurities such as segregation, porosity, and slag inclusions, leading to a tighter structure and improved plasticity and mechanical properties.

The mechanical properties of castings are generally lower than those of the same material in forgings. Furthermore, the forging process ensures the continuity of the metal’s fiber tissue, preserving the consistency of the forgings’ shape and metal flow integrity.

Precision die forging, cold extrusion, and temperature extrusion processes can produce forgings with excellent mechanical properties and long service life, which is unmatched by castings.

(1) The mechanical properties of forgings in the axial and radial directions are more consistent compared to rolled products.

This means that forgings have a much higher degree of isotropy, resulting in a longer lifespan compared to rolled products.

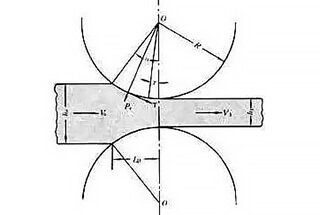

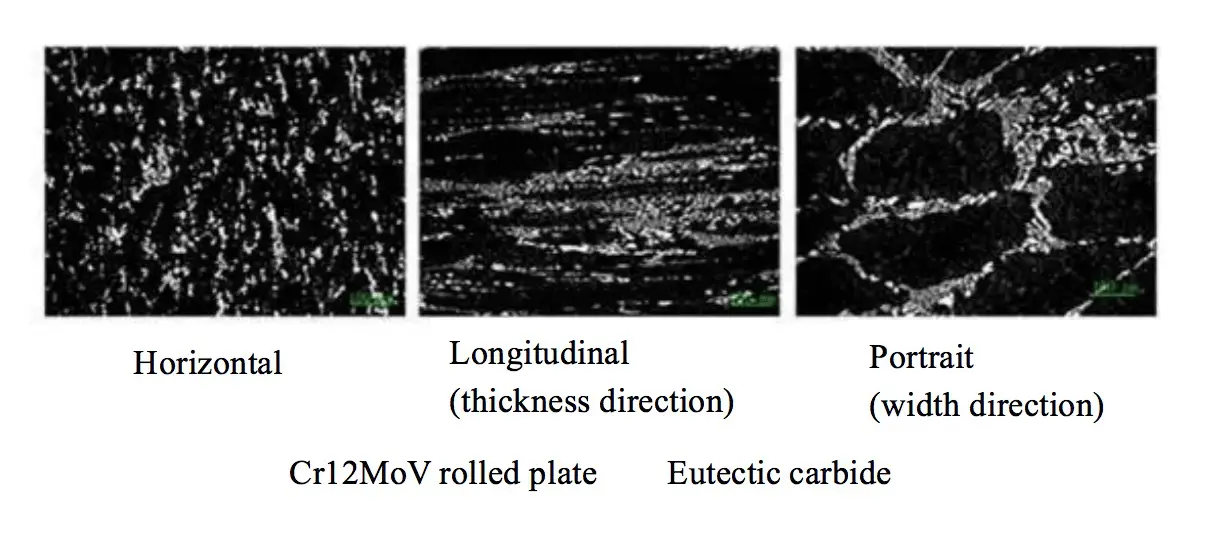

The figure below illustrates the metallographic diagram of eutectic carbides in different directions of a Cr12MoV rolled sheet.

(2) In terms of the degree of transformation, the deformation degree of forging is much greater than that of rolling, meaning that forging is more effective than rolling in breaking eutectic carbide.

(3) In terms of processing cost, forging is much more expensive than rolling.

For key parts, workpieces subjected to high loads or impacts, and workpieces with complex shapes or strict requirements, forging must be used.

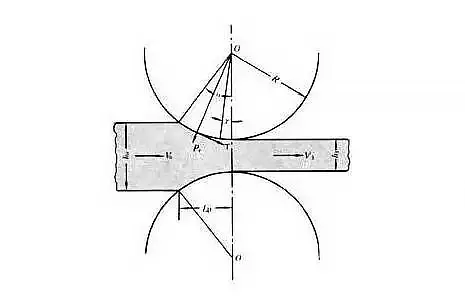

(4) Forged parts have complete metal flow lines.

Mechanical work after rolling destroys the integrity of metal flow lines, significantly shortening the life of the workpiece.

The picture below shows the metal flow lines of casting, machining, and forging workpieces.