1. Project background

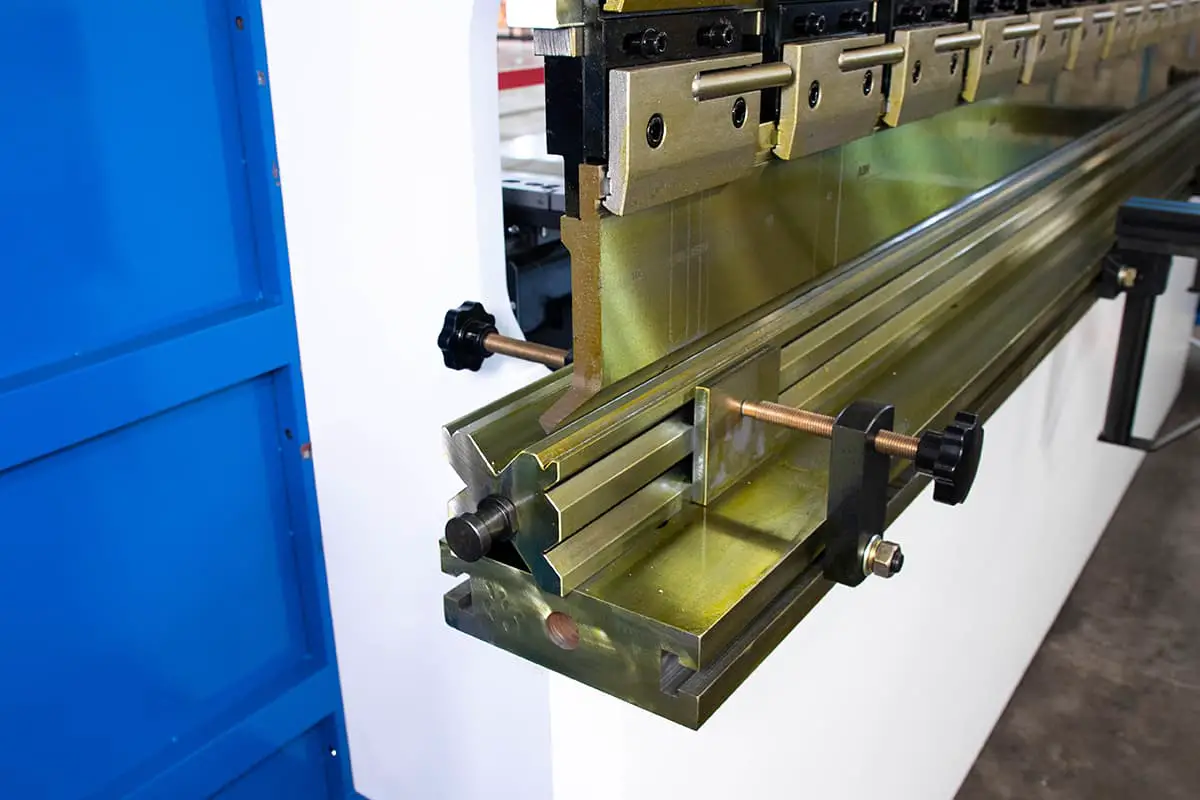

The 12 meter press brake bending machine primarily manufactures automobile components such as longitudinal beams, auxiliary beams, thickened crossbeams of connecting plates, as well as new, trial, and special-shaped products, and super long and ultra-thick connectors.

There are 8 thickness options, ranging from 3mm to 10mm.

The machine boasts 263 specifications and 554 varieties, with an average monthly production of 272 varieties.

As demand for heavy-duty vehicles continues to rise, there has been an increase in small and multi-batch production. However, the production cycle of the large-scale press brake machine is unable to keep up with these demands, leading to a prolonged supply cycle due to frequent adjustments.

2. The main deficiencies

2.1 Poor adjustment accuracy

The fixed dead positioning block is utilized in the adjustment and positioning mechanism of the system.

If the positioning block has become damaged, distorted, or worn over time, the four positioning points of the individual machine will become misaligned.

In order to accommodate repeated adjustments and trial moldings, it is necessary to add a gasket and insert plate.

2.2 Poor reliability

The impact force generated by large bending components on the positioning block is substantial, causing the fastening bolts of the positioning block to become loose, the insert plate to shift, and the positioning deviation to exceed 2mm, resulting in a deviation in the formed dimensions.

To ensure accurate bending dimensions, it is necessary to adjust and secure the positioning point twice.

2.3 Extended production cycle

The frequent adjustments required for the gasket and insert plate are cumbersome and prolong the batch production cycle, making it difficult to meet delivery schedules.

To address these issues, we propose a transformation plan for the positioning system of the large-scale press brake machine.

3. Modification scheme

The insert plate position adjusting mechanism is changed to a screw type design.

Three holes are drilled in the original positioning block plate, and two of them are fitted with adjustable bolts, which makes debugging and installation more convenient.

3.1 Working principle of the system

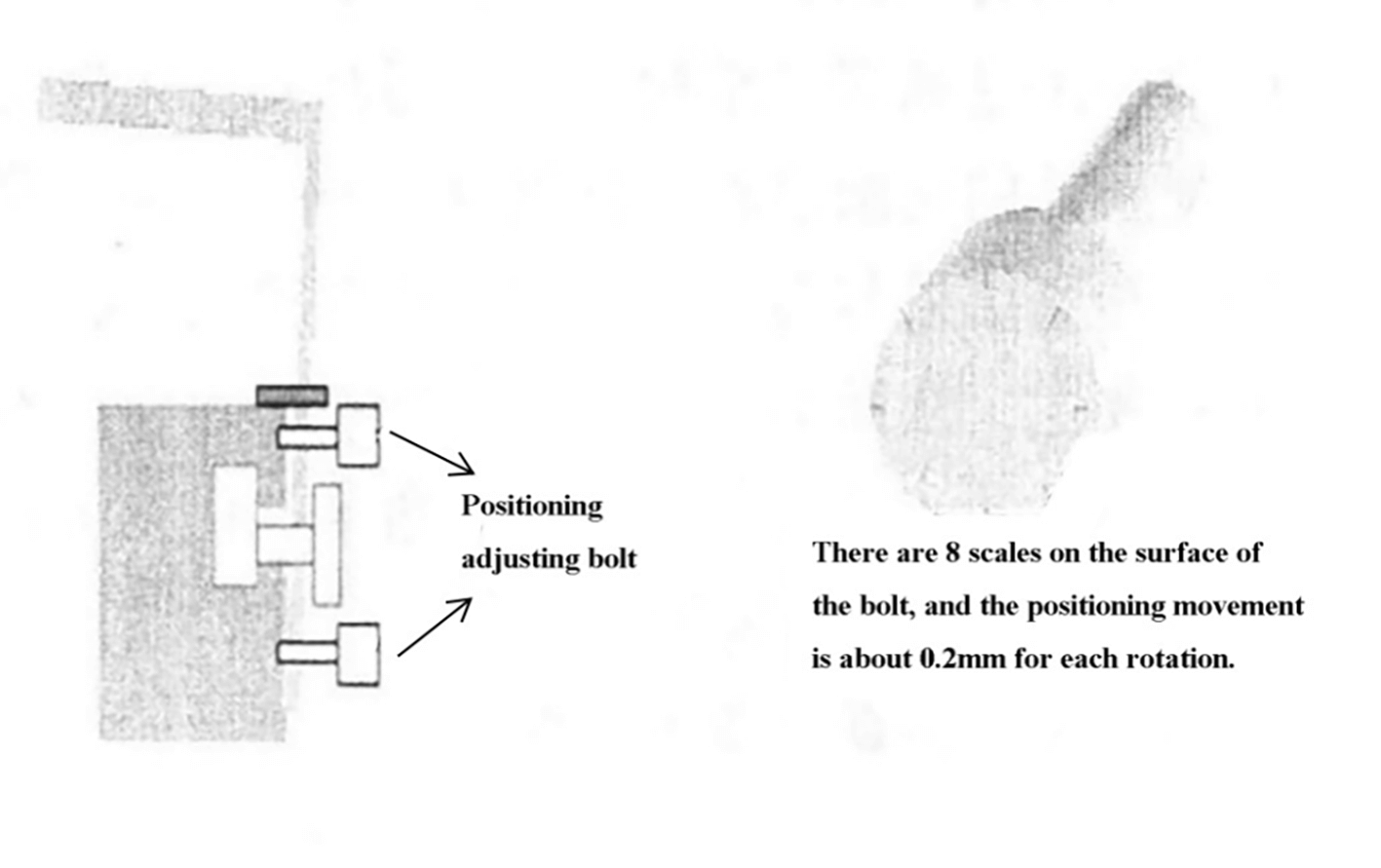

This device is a precision feed adjustment device, known as a threaded adjustment device.

As shown in the illustration below, the accuracy of the system is adjusted by adjusting the upper and lower bolts.

Instructions for adjusting the positioning block: (for one person operation)

- Use a hex wrench to loosen the fastening bolt of the positioning block.

- Hold the positioning block with one hand to prevent it from rotating sideways.

- Use a wrench to rotate either the upper or lower adjusting bolts, moving the positioning block forward or backward.

- After positioning, tighten the bolt of the positioning block using the hex wrench.

The threaded adjustment device offers this major advantage in the adjustment process.

System simplified block diagram

3.2 Work plan and technical solutions

| NO. | Scheme | Project | Take on | Plan implement (August) | Confirm | ||

|---|---|---|---|---|---|---|---|

| 1st-10th | 13th-18th | 20th-25th | |||||

| 1 | Design, Manufacture, and Installation: | On-site measurement | ____ | 08.02 | OK | ||

| Design graphics | ____ | 08.07 | OK | ||||

| Machining | ____ | 08.09 | OK | ||||

| 2 | Installation and debugging | ____ | 08.09 | OK | |||

| Effect tracking | ____ | 08.13-08.25 | OK | ||||

During periods of downtime, we improve the positioning accuracy of the large bending machine without affecting production.

To accomplish this task in a short amount of time, we first familiarize ourselves with the positioning structure of the equipment, remove any devices that need to be replaced, install the new positioning block adjustment device, and then perform the necessary debugging.

We employ a strategy of technical preparation in advance, utilizing multi-channel parallel and cross-functional operations. The installation and debugging work can be completed within one week, allowing the equipment to be put into operation and shortening the transformation time while ensuring production.

4. Economic benefit and effect after use

The positioning block’s adjustment time has been reduced from 64 minutes to 22 minutes per day. This results in an average daily decrease of 42 minutes, calculated over 23 working days per month. This equates to a total decrease of 966 minutes, equivalent to an increase of 2.01 work shifts. The reduction in adjustment time will allow for the completion of 26 additional species, ensuring that the delivery of parts will not be impacted.

5. Final thoughts

The application of new technology, materials, and techniques to modernize old equipment has a promising outlook. Our company is facing the challenges of global economic competition, and many of our existing equipment needs to be updated. This process can save a significant amount of money for the enterprise, improve working conditions for employees, increase processing accuracy and efficiency, conserve energy, and reduce equipment failure rates.