Arc bending processing of sheet metal: arc processing can be divided into ordinary tool processing or arc tool processing (radius punch and rounding punch). 1. Bending arc with standard punch The process of arc bending involves the following steps: 1. Select a 0.2R ordinary punch and die that adheres to the die selection standard. 2. […]

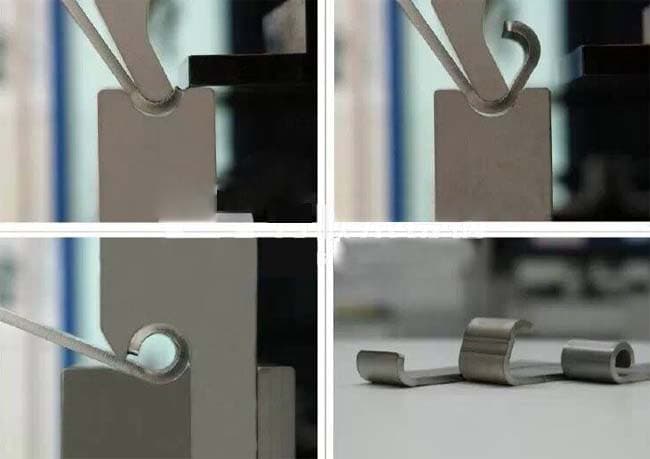

Arc bending processing of sheet metal: arc processing can be divided into ordinary tool processing or arc tool processing (radius punch and rounding punch).

The process of arc bending involves the following steps:

1. Select a 0.2R ordinary punch and die that adheres to the die selection standard.

2. Calculate the length of the arc.

3. Determine the number of bends needed to complete the arc by dividing the arc length by the material thickness.

4. Compute the bending angle for each bend by dividing the arc angle by the number of bends.

5. Perform the bending process.

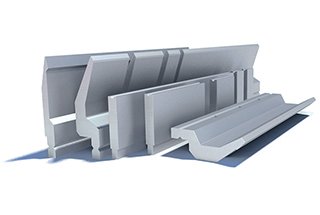

However, because the arc bending process is completed by bending several or even dozens of times, the size range of the bending arc is limited by the toolings.

General processing scope:

1) 90 degree circular arc: forming circular arc larger than R12;

2) Circular arc above 120 degrees: it can process all R circular arcs that are greater than the tool limit.

The choice of tool is dependent on the method of processing.

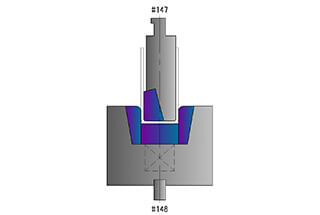

For instance, the width of the V-groove is determined by the depth of the bend.

Related reading: Press Brake Bending Depth Calculator

The circular arc R angle is formed based on the inherent R angle of the tool.

When selecting the die, if the bend radius is less than R12, an upper and lower die with processing specifications can be selected for a single bend.

Since the R punch is a standard mold, its R specification is limited, therefore the size of the processed arc specification is limited as well.

If the desired bend radius is not within the standard mold specification, it can be increased by adding material around the R mold.

If the bend radius is greater than R12, it will need to be formed through multiple bends, with the same processing conditions as those for standard punch arc bending.

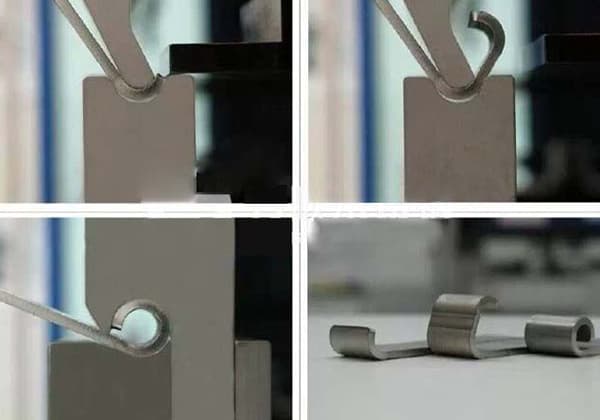

Arc bending with a radius punch has the advantage of producing a smooth and attractive bend, making it suitable for products with strict appearance requirements.

1)When bending an arc with a radius punch, it is important to first choose the mold based on the mold selection standard. However, when processing a 90-degree arc, the sheet metal parts may rebound and prevent the 90-degree arc from meeting the requirements. In this case, manual intervention is necessary to ensure the proper angle. To avoid this issue, an 88-degree lower die should be preferred when processing a 90-degree circular arc.

2)During the arc processing, it is necessary to use a detection fixture to ensure the size of the processed appearance.

3)The process angle arc is typically processed using either an interchangeable die or by manual means.

4)To determine the width standard of the lower die V-groove, use an R die (round bar and arc punch) to fold the arc.