How can a simple bend in sheet metal impact both safety and profits? In this article, we’ll explore the critical safety measures in the sheet metal bending process. Learn how to protect workers from mechanical and electrical hazards while ensuring efficient production.

The process of bending sheet metal is not only crucial for the smooth execution of an enterprise’s production plan, but also significantly impacts its economic benefits.

As a result, the safety of this process has garnered increased attention from both businesses and society.

Production management personnel in an enterprise should not only prioritize the safety of the operators using the bending machine, but also conduct a comprehensive assessment of potential hazards affecting the machine. They should then implement appropriate safety measures to ensure the protection of front-line workers in the workshop.

Throughout the production process, a competent production manager must prioritize the safety of employees, as it is the most crucial aspect of production.

Typically, the main sources of hazards during the operation of a press brake machine include mechanical and electrical hazards.

Mechanical injury refers to an accident caused by the unintended release of mechanical energy. It is one of the most common hazards in the production process and has various sources.

The main sources of mechanical injury include:

(1) The operator of the press brake machine must not insert any part of their body between the upper and lower molds, such as reaching their hand in to adjust the position. This is because the upper mold or rear positioning of the press brake may collide with their hand, putting their safety at risk.

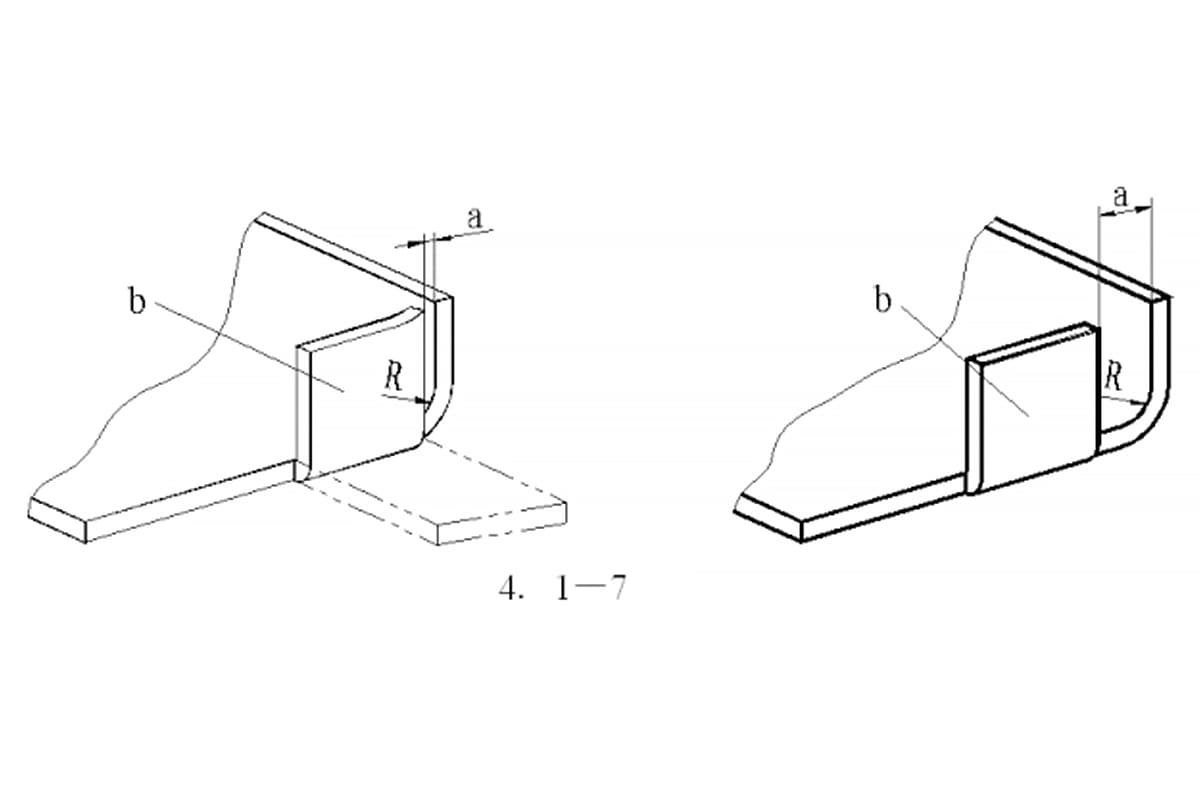

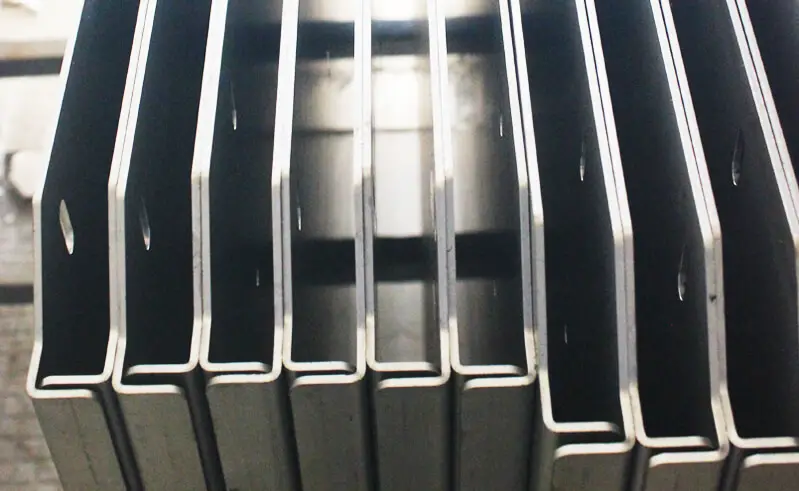

(2) When bending large or heavy parts, two people need to work together to complete the operation (as shown in Figure 1).

Fig. 1 Parts pushed by two people during bending

At the same time, both operators must push the parts to the specified position simultaneously. When pushing parts, they must work together.

This requires good cooperation skills between the operators and between the operators and the machine. If not executed properly, the probability of accidents increases, and the parts may collide with their heads during descent, posing a threat to their safety.

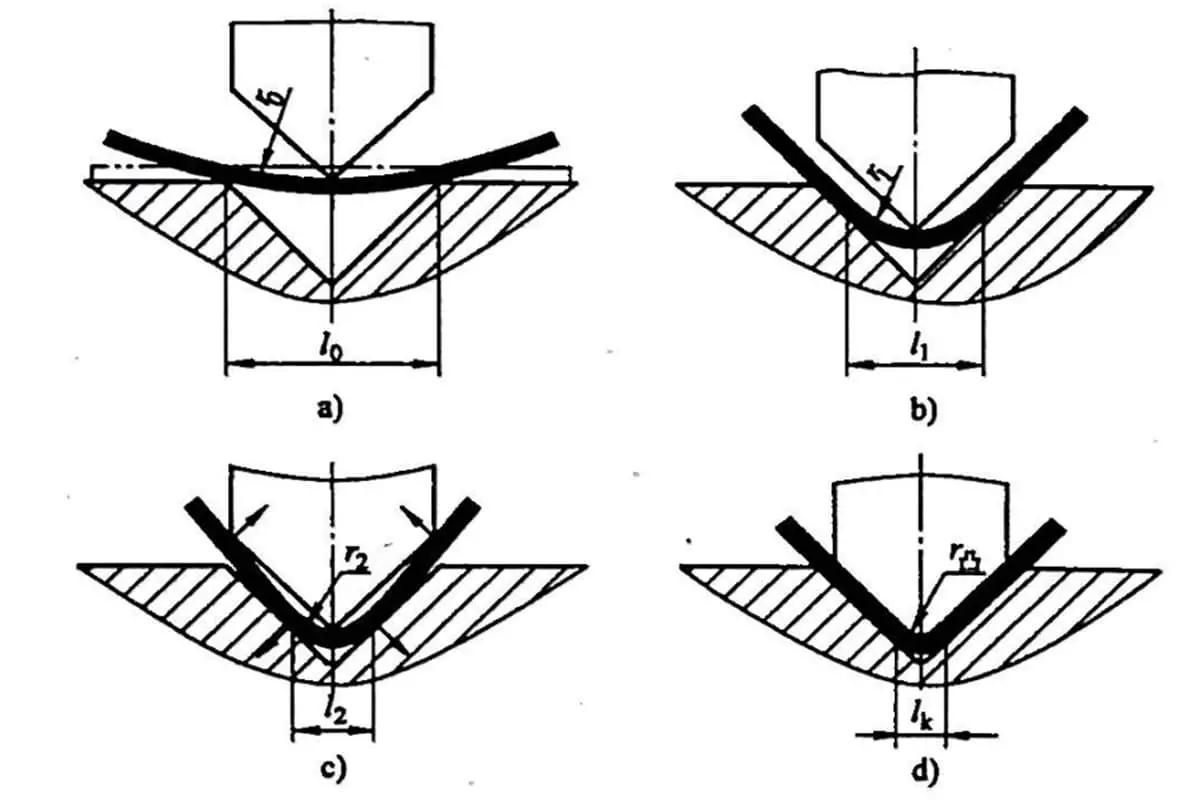

(3) The press brake machine operates by pushing the parts by hand while stepping on the control switch, which activates the hydraulic pressure to move the upper and lower dies, thus bending the parts.

If an operator is not careful when bending a small part or a part smaller than the upper die of the bending machine, their hand may become caught between the upper die and the part due to incorrect bending techniques.

Figure 2 shows the hand between the upper and lower dies during the bending of small parts.

Fig. 2 Hand between upper and lower dies when bending small parts

(4) During the operation of the press brake machine, it is important to avoid stacking materials too high, which may cause parts to fall and injure the legs or feet of workers. Additionally, materials should not be placed too close to the bending machine to prevent parts from scratching workers when they turn around.

(5) When two people operate the bending machine, if the double foot switch is not activated, one person may begin stepping on the switch while the other is still adjusting the position of the parts. This may result in parts scratching the operator or hitting their chin.

Furthermore, during the process of pushing parts, the sharp edges of some parts may scratch the hands of inspectors.

Figure 3 shows the situation of two people stepping on the foot switch.

Fig. 3 Double pedal switch

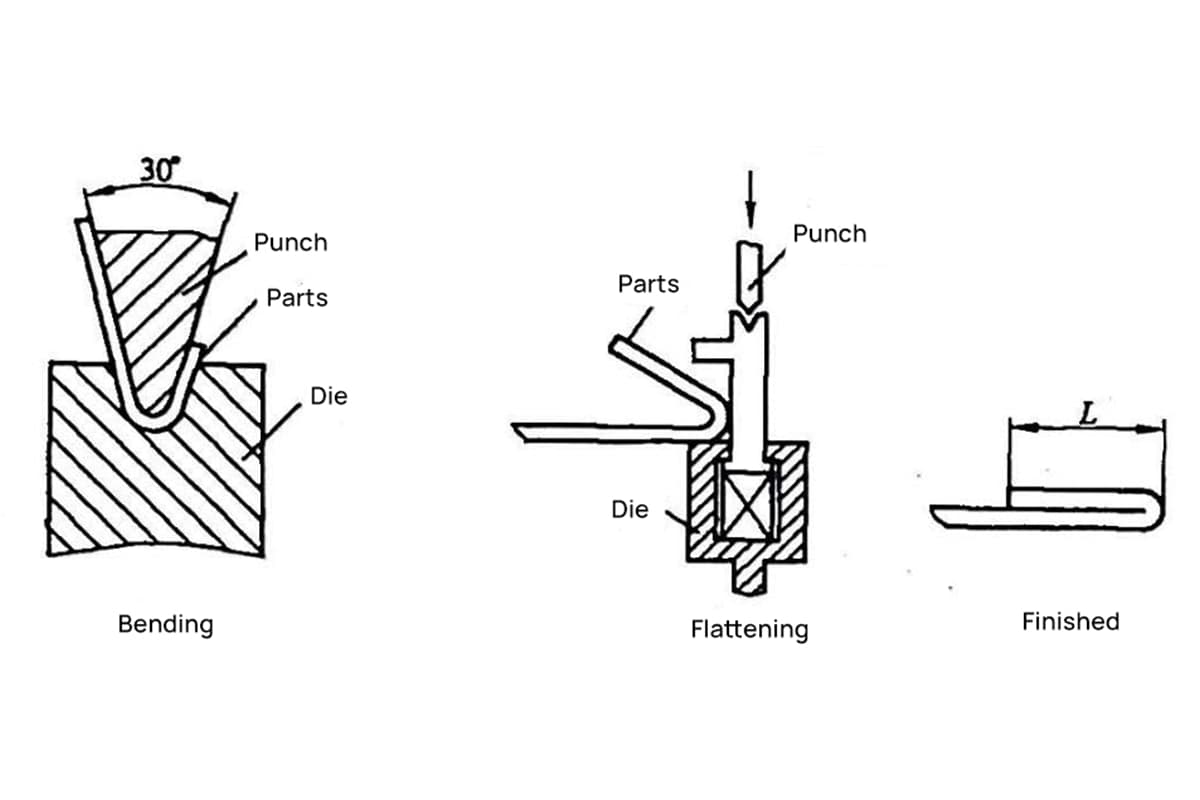

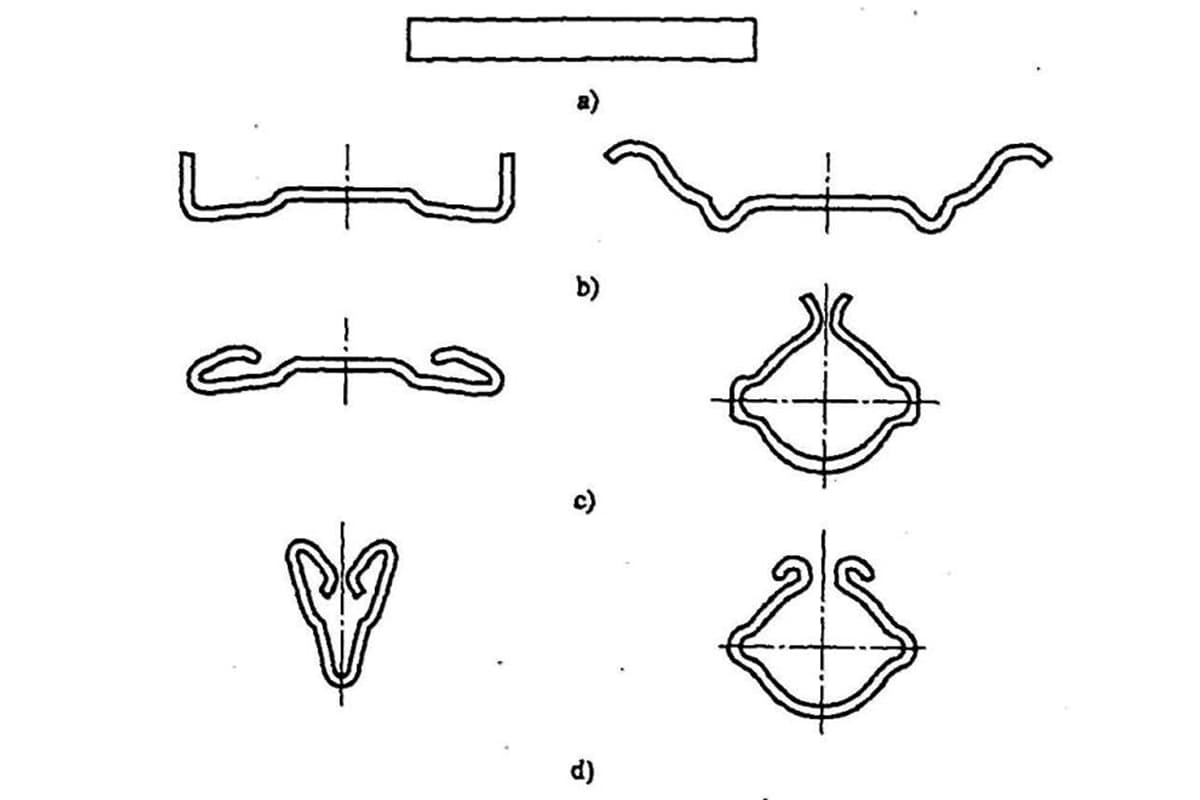

(6) Bending is an intermediate process that involves plate cutting and punching in the preceding step and subsequent viscose, welding, and assembly processes.

After the completion of the previous process, the parts must be lifted for bending or placed on a pallet or trolley and transported to the next process after bending is completed.

During the process of placement, lifting, and transportation, parts may fall and cause injury or crush personnel.

Electrical injury is the most direct threat to the human body among accidents caused by bending machines, and the main sources of electrical hazards include:

(1) Poor quality tools and instruments used by personnel during the operation of the bending machine may result in electric shock accidents. The motor and lighting facilities may also emit excessive heat energy after being powered on, causing burns if not handled carefully.

(2) Over time, some wires on the bending machine may become damaged, and if a wire is partially exposed, the operator or maintenance personnel may experience an electric shock due to the damage.

(3) Operators may also experience electric shock if they do not follow regulations when operating electrical equipment. Furthermore, the continuous movement of air around electrical equipment may generate static electricity, causing sparks and potentially leading to a fire.

(1) To ensure safety, the operator of the bending machine must perform protective measures before starting the operation, such as wearing anti-slip shoes, gloves, and a safety helmet. Additionally, operators from the preceding process must remove large burrs on the bending parts.

(2) Standardize the safety production process of the bending machine. Develop procedures for the production of the bending process and transportation of parts, including safe operation procedures for mechanical handling and lifting, safe operation procedures for transportation and storage of parts, and operation instructions for the bending process and other guidance documents for machine operation. This will ensure that operators use tools and machines correctly, thus promoting their own safety.

(3) Ensure the safety of the position of the parts to be bent and the finished parts. Operators must pay attention to maintaining a synchronous relationship between the machine and the worker, and the bending work area must be isolated with guardrails.

(4) Visual management is emphasized in the safety management of the bending process. This means that safety management states and methods are clearly visible and easy to understand, so that employees can understand, accept, and independently implement safety measures.

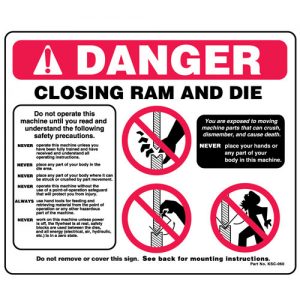

A danger source information board (Figure 4) is posted above the press brake machine on the bending production site, highlighting potential safety hazards in the bending operation area, and warning that improper operation of the press brake may cause injury to operators or other personnel handling parts.

Fig. 4 Danger source information Kanban on bending production site

The analysis of hazard sources in the bending operation area highlights that the door panel and other parts are long and heavy, and the speed at which they are lifted and dropped during bending is too fast. Inattention by the operator to the presence of people near the bending machine is also identified as a contributing factor.

(1) The operator of the press brake machine must wear protective gear during electrical inspections. Illegal operation is strictly prohibited during the inspection. Before conducting the inspection, it is crucial to carefully check the wires for damage and leakage. If any such conditions are found, the inspection must be stopped immediately.

(2) When checking the circuit and instrument, ensure that the power supply is disconnected. To reduce the risk of inspection, red warning signs must be posted on the surrounding guardrails. During the inspection, avoid using temporary power supplies and circuits to prevent leakage and fire.

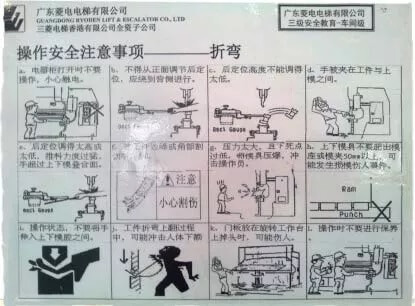

(3) To increase the effectiveness of visual management, comics and text descriptions of safety precautions for bending operations (Figures 5 and 6) and switch status signs for the photoelectric device of the bending machine should be posted above the machine.

Fig. 5 Safety precautions for bending

Fig. 6 Pasting position of safety information

In conclusion, there are numerous potential safety hazards in the production process of bending. It is imperative to have a comprehensive understanding of these hazard sources and take proactive measures to ensure personal safety. Only then can we carry out production and work safely.