With the rapid advancements in modern science, technology, and the industrial sector, tubular components play an increasingly crucial role across various industries including construction machinery, transportation, agricultural machinery, kitchenware, and fitness.

Concurrently, the emergence and rapid development of CNC laser tube cutting machines have accentuated the benefits of laser tube cutting.

Laser cutting, with its unique attributes of narrow cut width, minimal thermal effects, swift cutting speeds, neat cuts, excellent flexibility, and no apparent constraints on the shape, type, or thickness of the tube being cut, stands out when compared to traditional tube processing methods.

Laser tube cutting technology enhances cutting quality, ensures processing efficiency, simplifies the workflow, and significantly increases the economic benefits for a vast number of laser tube cutting users.

However, laser cutting tubes is a complex process, with various factors influencing the cutting outcome. It’s vital to analyze issues arising during the process and develop methods to address them.

There are primarily four reasons for incomplete or rough cuts during the laser cutting process:

1. Cutting at excessive speeds

Especially when working with special tubes or those with high thickness like profiles or irregularly shaped tubes.

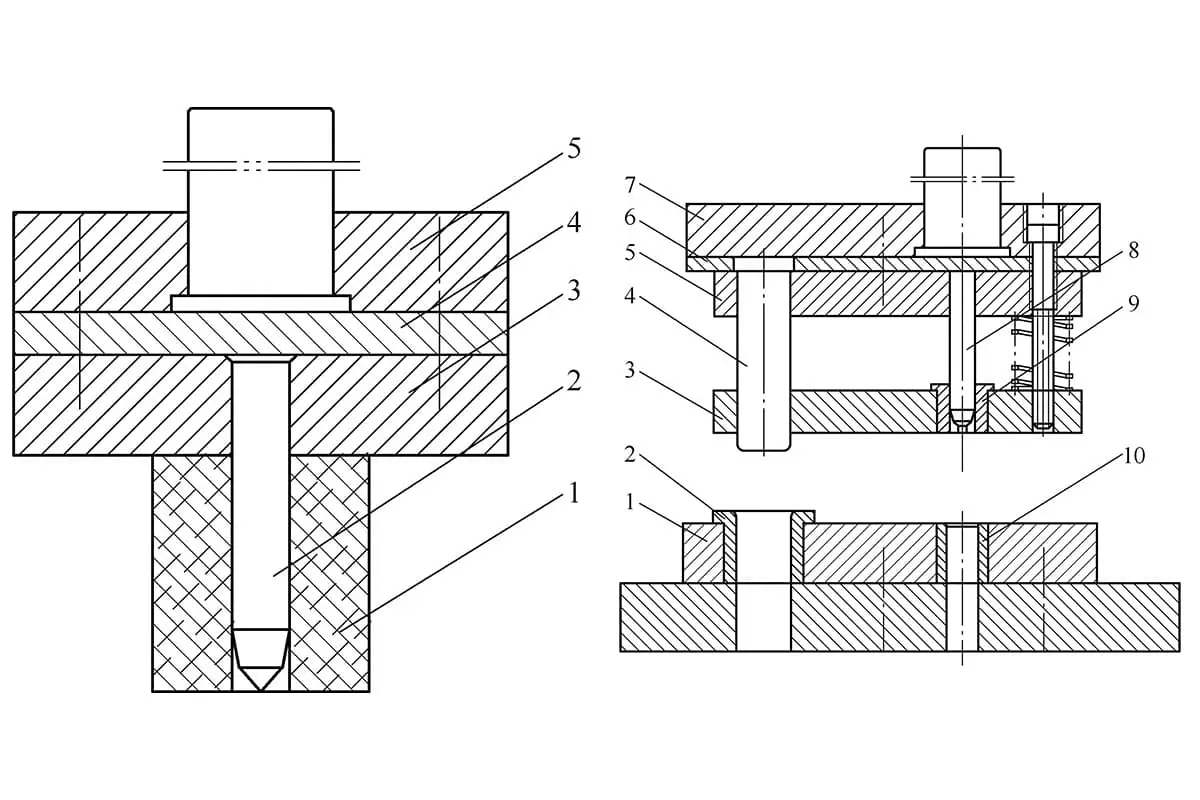

When the cutting head reaches a corner, where the thickness increases, cutting too quickly can lead to incomplete or rough cuts, as shown in Figure 1.

In such scenarios, it’s common practice to reduce the cutting speed at corners and increase the pressure of the assisting gas.

2. Incorrectly adjusted focal length of the cutting head or an improperly aligned laser path.

The focal length can significantly affect tube cutting quality.

Standard cutting head focal settings include negative, zero, and positive focus.

Positive focus is suitable for oxygen cutting of carbon steel, zero focus is apt for thin sheet cutting, and negative focus is ideal for materials like stainless steel, galvanized carbon steel, aluminum, copper, etc., requiring nitrogen/air cutting.

Thus, choosing the correct focal position for various tubes is essential. An improperly aligned laser path also impacts tube cutting significantly.

Therefore, during trial cuts, it’s vital to continuously adjust the beam’s position to achieve a perfectly circular spot on the test material.

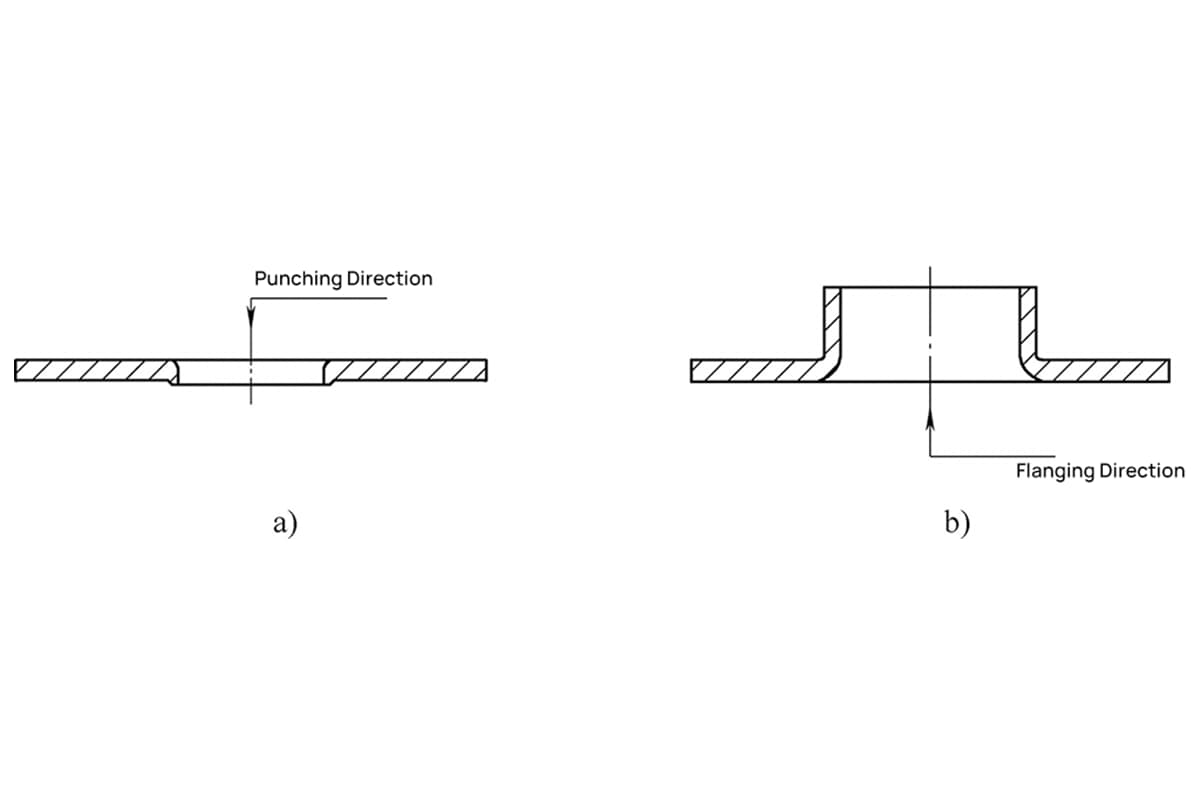

Contaminated protective lenses, as illustrated in Figure 2.

3. The cutting head protective lens and focusing lens are contaminated, and the water source for the cooling system is unclean.

While the normal cutting procedure continually cools and removes slag with the assisting gas, the protective and focusing lenses can easily get contaminated due to high temperatures during cutting. If these lenses are polluted, it could lead to incomplete cuts or failures in tube cutting.

Moreover, using impure water in the laser cutting system, at best, can affect its cooling efficiency, leading to clogged cutting head and generator water channels, impacting the tube cutting quality.

At worst, it could damage the generator and cutting head, resulting in significant economic losses.

Hence, it’s paramount to use purified water, preferably distilled, to prevent blockages and cooling issues.

4. Excessive laser output power or inappropriate nozzle selection for the cutting head.

When laser cutting symmetrical tubes, like round or square tubes, excess power can cause melt borders.

These molten residues can accumulate on the interior side of the opposite face, effectively adding thickness. This buildup can obstruct subsequent cutting passes, making it hard to achieve a complete cut and leaving a rough finish.

Thus, it’s essential to conduct preliminary perforation and trial cutting tests to determine the optimal laser output power and assisting gas pressure.

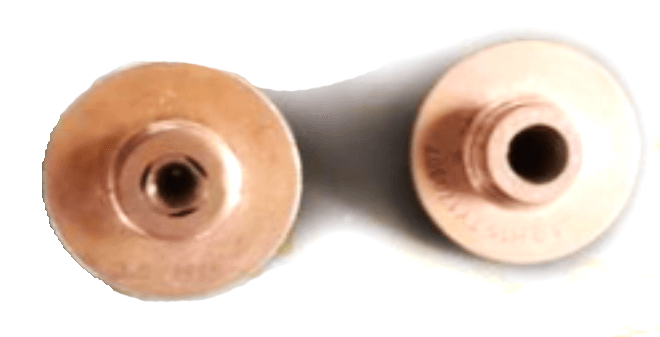

Nozzle selection also impacts cutting quality.

Typically, dual-nozzle setups are suitable for precise cutting slots in tubes, mainly used for thin, high-precision, and fast tube cutting, while single-nozzle configurations are suitable for thicker, varied material tubes with lesser precision requirements.

Trial cuts help in choosing the right nozzle for the tube, ensuring overall cutting quality and efficiency.

Inaccurate parameter settings for the machine axes.

Generally, a laser tube cutter comprises control axes like the X-axis rack and pinion drive, Y-axis lead screw drive, Z-axis cutting head, and W-axis rotating feeding chuck.

If parameters like gear pitch circle diameter, lead screw pitch, or transmission ratios are set incorrectly, it profoundly impacts the final cutting result. Some errors might even affect the machine’s proper functioning.

Before operating the machine, it’s crucial to ensure that the axis parameters are correctly set.

Misalignment of the X and Y axes or Z and X axes.

If the X and Y axes aren’t perpendicular, circular patterns cut on the tube surface might be distorted, as shown in Figure 4.

A square pattern might become a parallelogram. If the Z and X axes aren’t aligned, the cutting head’s path deviates, causing discrepancies between the simulated and actual cutting paths, leading to misalignment between the starting and end points, as seen in Figure 5.

This misalignment is one of the reasons for incomplete tube cuts. If such issues arise, immediate calibration using a micrometer is necessary, along with checking for any loose screws or wear and tear in the racks, lead screws, or gears.

Laser tube cutting has earned a significant position in the laser cutting industry.

Especially as laser tube cutters have evolved through manual, semi-automatic, and fully automatic phases, more individuals recognize their potential in production and processing.

This growing reliance underscores the need to identify and resolve various challenges encountered during laser tube cutting, continuously refine the cutting systems and techniques, and promote the development of high-speed, precision, automated, flexible, and multi-functional laser tube cutting. This is pivotal for the rapid advancement of the entire laser cutting industry.

As the founder of MachineMFG, I have dedicated over a decade of my career to the metalworking industry. My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for metals. I am constantly thinking, reading, and writing about these subjects, constantly striving to stay at the forefront of my field. Let my knowledge and expertise be an asset to your business.