Have you ever wondered what makes welding gases so essential yet complex? This article explores the diverse types of welding gases, their roles in protecting and stabilizing welds, and the critical impact they have on welding processes. You’ll discover the unique properties of gases like argon, carbon dioxide, and acetylene, and learn how to select the right gas for various welding and cutting applications. By the end, you’ll understand the significance of each gas and how it enhances welding efficiency and quality.

Welding gas mainly refers to the protective gas used in gas-shielded welding (such as carbon dioxide gas shielded welding and inert gas shielded welding) and the gas used in gas welding and cutting. This includes gases such as carbon dioxide (CO2), argon (Ar), helium (He), oxygen (O2), combustible gas, mixed gas, etc.

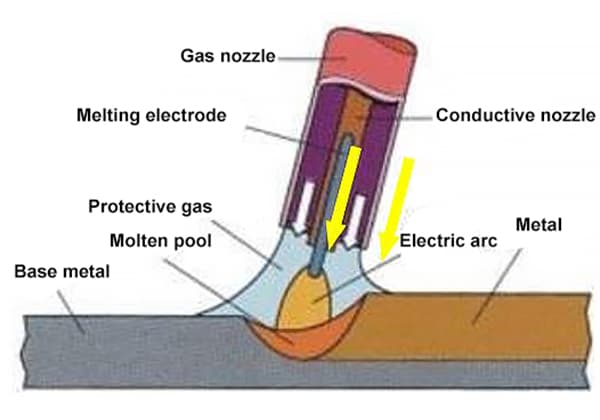

During welding, the shielding gas serves not only as a protective medium in the welding area but also as the gas medium generating the arc.

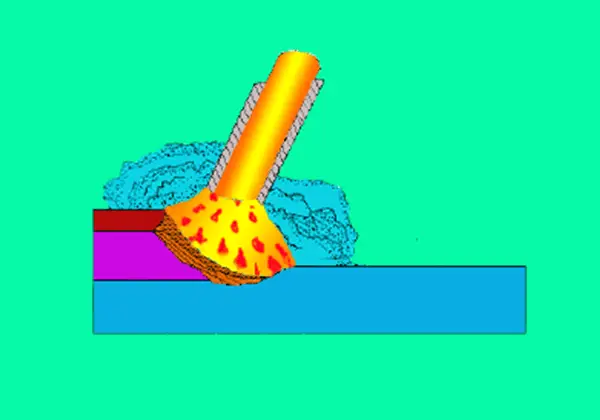

Gas welding and cutting primarily rely on the high-temperature flame with concentrated heat generated during gas combustion.

Therefore, the physical and chemical characteristics of the gas not only affect the protection effect but also influence the ignition of the arc and the stability of the welding and cutting process.

Welding gas refers to various gases used in welding or cutting. Depending on their role in the process, welding gases can be categorized into two types: shielding gas and gas for gas welding and cutting.

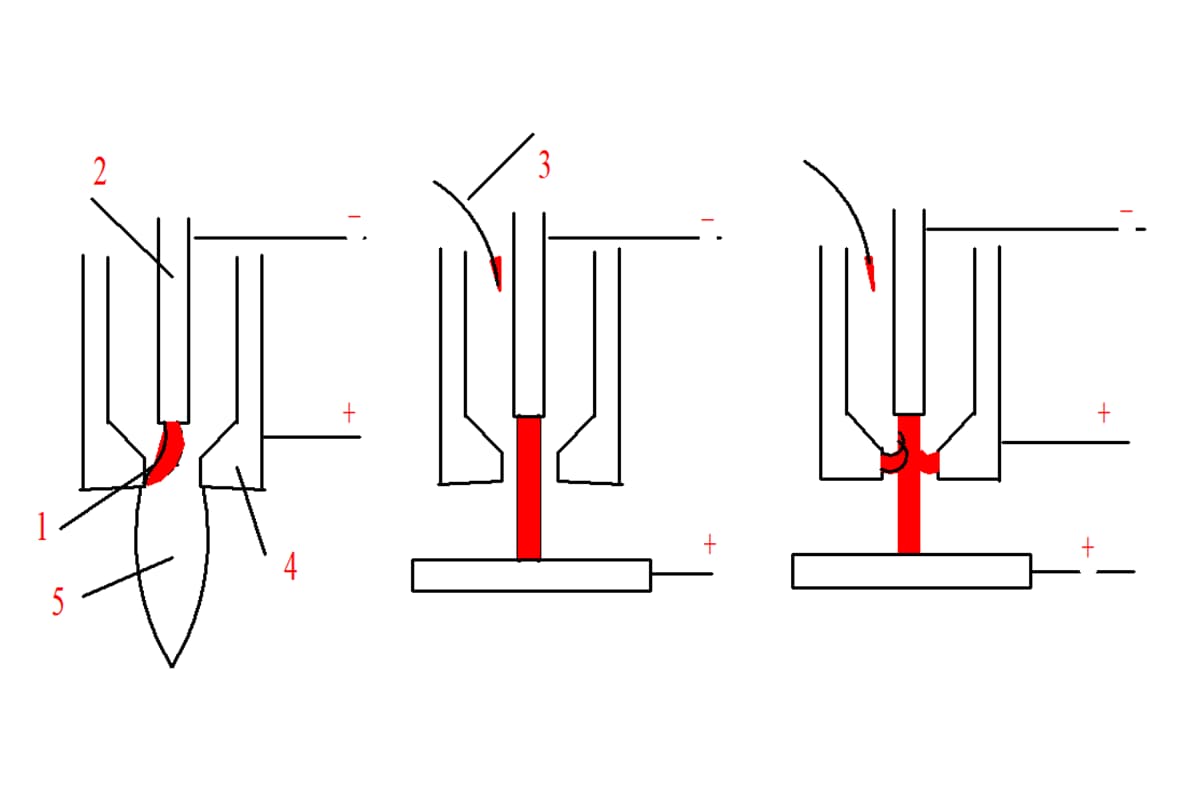

(1) Shielding gas:

Shielding gas is used in gas shielded welding to provide protection to the weld pool from the surrounding atmosphere. Commonly used shielding gases include carbon dioxide (CO2), argon (Ar), helium (He), oxygen (O2), nitrogen (N2), hydrogen (H2), and their mixtures (such as Ar + He, Ar + CO2, Ar + CO2 + O2, etc.).

The International Institute of Welding classifies shielding gases based on their oxidation potential: inert or reducing gas (Class I), weak oxidizing gas (Class M1), medium oxidizing gas (Class M2), and strong oxidizing gas (Classes M3 and C).

(2) Gas for gas welding and cutting:

Gas for gas welding and cutting is classified based on its nature into two types: combustion supporting gas (O2) and combustible gas. When combustible gas and oxygen are mixed and burned, they release a significant amount of heat, creating a high-temperature flame with concentrated heat that can melt the metal.

Acetylene (C2H2) is the most commonly used combustible gas in gas welding and cutting, while other widely used gases include propane (C3H8), propylene (C3H6), natural gas (mainly methane CH4), and liquefied petroleum gas (mainly propane).

The role of gas varies in different welding or cutting processes, and the selection of gas depends on the type of material being welded. This requires choosing gas with specific physical or chemical properties, or even a mixture of multiple gases, depending on the occasion.

Table 1 outlines the primary properties and uses of gases typically used in welding and cutting, while Table 2 illustrates the characteristics of different gases during the welding process.

Table 1 Main characteristics and uses of common welding gases

| Gas | Symbol | Main properties | Application in welding |

|---|---|---|---|

| Carbon dioxide | CO2 | Stable chemical properties;Non combustion and non combustion supporting; It can decompose into CO and o at high temperature and has certain oxidation to metals; Can liquefy;When liquid CO2 evaporates, it absorbs a lot of heat and can solidify into solid carbon dioxide, commonly known as dry ice | Welding wire can be used as shielding gas during welding, such as CO2 gas shielded welding and CO2 + O2, CO2 + a mixed gas shielded welding |

| Argon | Ar | Inert gas;The chemical property is not active, and it does not play a chemical role with other elements at room temperature and high temperature. | It is used as shielding gas for mechanical protection during arc welding, plasma welding and cutting. |

| Oxygen | O2 | Colorless gas;combustion-supporting;It is very active at high temperature and directly combines with many elements; During welding, oxygen entering the molten pool will oxidize metal elements and play a harmful role. | Mixed combustion of oxygen and combustible gas can obtain extremely high temperature for welding and cutting, such as oxygen acetylene flame and hydrogen oxygen flame. It can be mixed with argon and carbon dioxide in proportion for mixed gas shielded welding |

| Acetylene | C2H2 | Commonly known as calcium carbide gas;Less soluble in water, soluble in alcohol, a large amount soluble in acetone;Mixed with air and oxygen to form explosive gas mixture; It burns in oxygen and emits 3500 ℃ high temperature and strong light | For oxyacetylene flame welding and cutting |

| Hydrogen | H2 | Can burn;It is not active at room temperature and very active at high temperature;It can be used as reducing agent for metal ore and metal oxide; During welding, a large amount of molten metal can be precipitated during cooling, which is easy to form pores. | Hydrogen is used as reducing shielding gas during welding. Mixed combustion with oxygen can be used as the heat source of gas welding |

| Nitrogen | N2 | Inactive chemical properties;It can combine directly with hydrogen and oxygen at high temperature;Entering the molten pool during welding is harmful; It basically does not react with copper and can be used as protective gas | When nitrogen arc welding, copper and stainless steel can be welded with nitrogen as shielding gas. Nitrogen is also commonly used in plasma arc cutting as an outer protective gas. |

Table 2 characteristics of different gases during welding

| Gas | pure | Column position gradient | Arc stability | Metal transition characteristics | Chemical properties | Weld penetration shape | Heating characteristics |

| CO2 | 99.90% | high | satisfied | satisfied, but some splashes | Strong oxidation | Flat shape, large penetration | |

| Ar | 99.995% | low | good | satisfied | Mushroom shaped | ||

| He | 99.99% | high | satisfied | satisfied | Flat shape | The heat input of butt weldment is higher than that of pure ar | |

| N2 | 99.90% | high | bad | bad | Pores and nitrides are produced in steel | Flat shape |

The appropriate gases should be utilized for CO2 gas shielded welding, inert gas shielded welding, mixed gas shielded welding, plasma arc welding, brazing in a protective atmosphere, oxygen acetylene gas welding, and cutting.

The choice of welding gas primarily relies on the welding and cutting methods employed. Additionally, it is also influenced by the properties of the welded metal, the quality standards of the welded joint, the thickness of the welded structure, the welding position, and the process utilized.

3.1. Select gas according to the welding method

The gases used for welding, cutting, or gas shielded welding vary depending on the different welding methods utilized during the welding process.

Table 3 provides information on the selection of welding methods and corresponding welding gases. Meanwhile, Table 4 outlines the selection of common brazing gases used in protective atmospheres. Table 5 shows the suitability of various gases for plasma arc cutting.

Table 3 selection of welding methods and welding gases

| Welding method | Welding gas | |||||

|---|---|---|---|---|---|---|

| Gas welding | C2H2+O2 | H2 | ||||

| Gas cutting | C2H2+O2 | Liquefied petroleum gas+O2 | coal gas+O2 | natural gas+O2 | ||

| Plasma arc cutting | air | N2 | Ar+N2 | Ar+H2 | N2+H2 | |

| Tungsten inert gas welding (TIG) | Ar | He | Ar+He | |||

| Solid wire | Inert gas metal arc welding (MIG) | Ar | He | Ar+He | ||

| Active gas metal arc welding (MAG) | Ar+O2 | Ar+CO2 | Ar+CO2+O2 | |||

| CO2 gas shielded welding | CO2 | CO2+O2 | ||||

| Flux cored wire | CO2 | Ar+O2 | Ar+CO2 | |||

Table 4 Selection of common brazing gases in protective atmosphere

| Gas | Nature | Chemical composition and purity requirements | Purpose |

| Argon | inertia | Argon > 99.99% | Alloy steel, thermal strength alloy, copper and copper alloy |

| Hydrogen | Reducibility | Hydrogen 100% | Alloy steel, thermal strength alloy and oxygen free copper |

| Decomposing ammonia | Reducibility | Hydrogen 75% nitrogen 25% | Carbon steel, low alloy steel and hydrogen free copper |

| Decomposing ammonia with insufficient compression | Reducibility | Hydrogen 7% ~ 20% and other nitrogen | mild steel |

| Nitrogen | It is inert relative to copper | Nitrogen 100% | Copper and copper alloys |

Table 5 Applicability of various gases in plasma arc cutting

| Gas | Main purpose | Remarks |

| Ar,Ar+H2, Ar+N2, Ar+H2+N2 | Cutting stainless steel, non-ferrous metals or alloys | Ar is only used for cutting thin metals |

| N2, N2+H2 | N2, as the working gas of water recompression plasma arc, can also be used to cut carbon steel | |

| O2, Air | Cutting carbon steel and low alloy steel, also used for cutting stainless steel and aluminum | Important aluminum alloy structural parts are generally not used |

| Carbon dioxide | Decomposing ammonia | Ar+CO2 |

| Nitrogen | C2H2+O2 | CO2+02 |

| Argon | LPG + O2 | Ar+O2 |

| Oxygen | Ar+N2 | Ar+H2+N2 |

| Acetylene | N2+H2 | Welding mixture |

| Hydrogen | Ar+H2 | Ar+He |