Have you ever wondered how massive steel structures are cut with such precision? Gas cutting, a remarkable yet often unsung process, has revolutionized the metal fabrication industry. In this article, we’ll delve into the science behind gas cutting, explore its applications, and discover how it has transformed the way we shape and create with metal. Get ready to be amazed by the power and versatility of this cutting-edge technology!

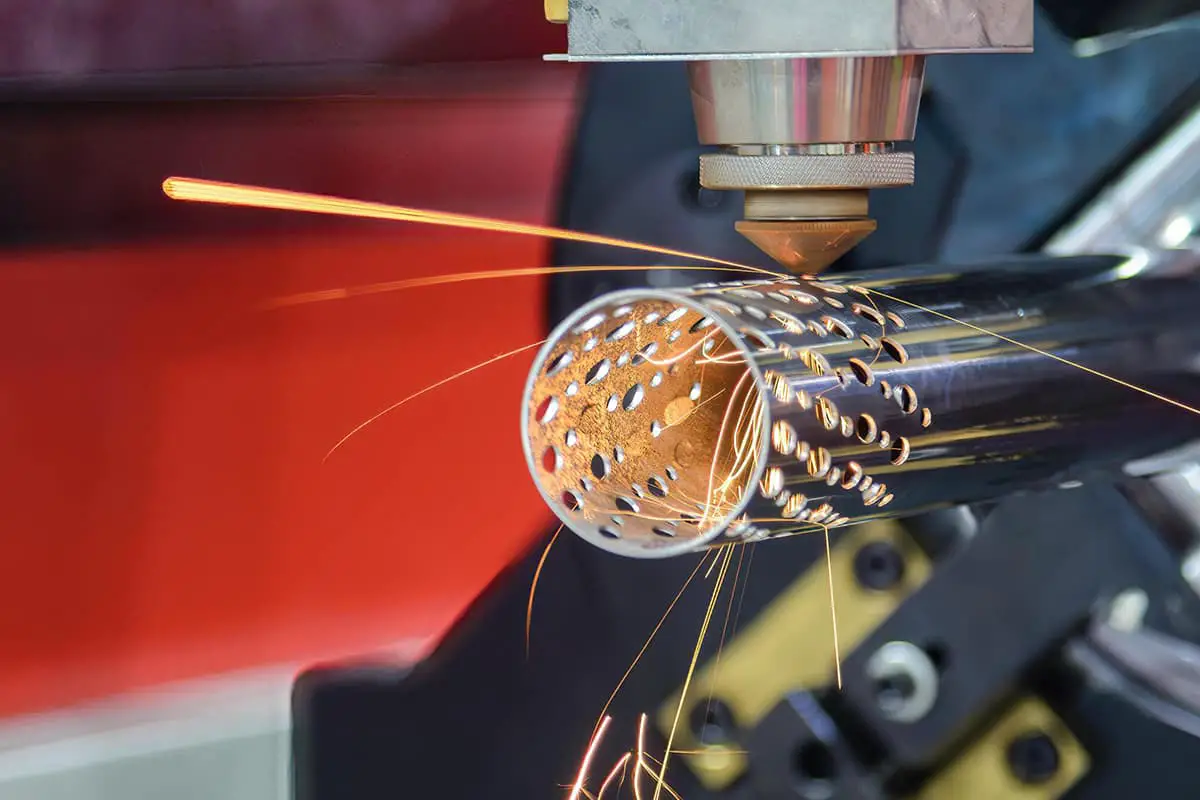

Oxy cutting, also known as oxyacetylene cutting or flame cutting, is a highly effective cutting process in equipment manufacturing.

Oxy cutting equipment is simple and easy to operate, making it suitable for cutting carbon steel and ordinary low alloy steel. It can accurately cut straight lines, circles, and various complex shapes, with a wide range of cutting thicknesses.

It is also easily automated, especially with the application of CNC technology, photoelectric tracking technology, and higher quality cutting nozzles, this trend is becoming more evident. Gas cutting produces clean cutting edges and has a faster cutting speed. Additionally, oxy cutting can also directly cut bevels.

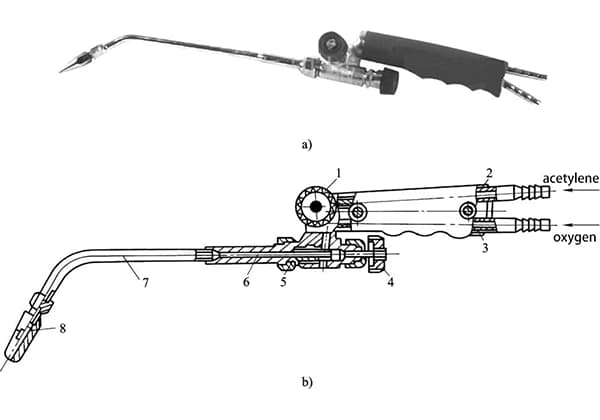

Gas cutting torch is used for thermal cutting of materials by mixing combustible gas with oxygen to produce a flame. It is also known as oxygen cutting or flame cutting.

During gas cutting, the flame preheats the material at the cutting point to its ignition temperature, and then oxygen is injected to cause a vigorous oxidation combustion of the metal material. The resulting oxide slag is blown away by the gas flow, creating a cut.

The purity of oxygen used for gas cutting should be greater than 99%. The combustible gas used is generally acetylene gas, but can also be petroleum gas, natural gas, or coal gas.

Acetylene gas provides the highest cutting efficiency and better quality, but it is more expensive. Gas cutting equipment mainly consists of the cutting torch and the gas source.

The cutting torch is the tool that generates the gas flame, transfers and regulates the cutting heat energy, and its structure affects the cutting speed and quality. The use of fast cutting nozzles can improve cutting speed, resulting in straight cuts and smooth surfaces.

For manual operation, gas cutting torches use oxygen and combustible gas cylinders or generators as the gas source. Semi-automatic and automatic gas cutting machines are equipped with cutting torch drive mechanisms or coordinate drive mechanisms, contour cutting mechanisms, photoelectric tracking or digital control systems.

Automatic gas cutting machines used for mass production can be equipped with multiple cutting torches and computer control systems.

The metal at the cutting point of the workpiece is preheated to its ignition temperature using an oxygen-acetylene flame, and then it is vigorously blown with a high-speed pure oxygen flow.

At this point, the metal undergoes intense oxidation, and the generated heat melts the metal oxide into a liquid.

At the same time, the oxygen flow blows away the molten oxide, resulting in a clean cut in the workpiece. By moving the cutting torch forward, the workpiece can be continuously cut.

To achieve oxygen cutting, the following conditions must be met:

1) The ignition temperature of the metal should be lower than its melting point.

2) The melting point of the metal oxide should be lower than the melting point of the metal.

Pure iron, low carbon steel, medium carbon steel, and ordinary low alloy steel meet the above conditions and have good gas cutting performance. High carbon steel, cast iron, stainless steel, as well as non-ferrous metals such as copper and aluminum, are difficult to be cut by oxygen.

3) Sufficient heat release during metal combustion:

Through testing and analysis, it has been determined that during the cutting of low carbon steel, approximately 70% of the total required heat is released during combustion, while flame preheating only accounts for 15%-30%. Therefore, this requirement can be met.

4) The thermal conductivity of the metal should not be too high:

The thermal conductivity of the metal should not be too high, as excessive heat loss from the preheating flame and heat release during the cutting process at the metal cutting point can prevent the cutting process from starting or continuing. For example, copper and copper alloys cannot be cut due to their high thermal conductivity.

5) Good fluidity of the generated oxide:

The generated oxide should have good fluidity. Otherwise, the oxide cannot be effectively blown away during cutting, hindering the cutting process.

Gas cutting machines are mechanized equipment that replace manual cutting torches for gas cutting. They have higher productivity, better cut quality, lower labor intensity, and lower costs compared to manual gas cutting.

1) Semi-automatic gas cutting machine:

It consists of a small carriage that automatically moves the cutting nozzle along a dedicated track, but the track trajectory needs to be manually adjusted.

2) Profile gas cutting machine:

Gantry type: The cutting nozzle is driven along the profile by wheels.

Swing arm type: The cutting nozzle is driven by a swinging arm mechanism.

3) Photoelectric tracking gas cutting machine:

This automated gas cutting equipment uses the principles of photoelectric tracking to automatically follow patterns and drive the cutting torch for profile cutting.

4) CNC gas cutting machine:

CNC stands for Computer Numerical Control, which is a new control method where instructions (or programs) for controlling machine tools or equipment are given in digital form. When these instructions are provided to the control equipment of a CNC automatic gas cutting machine, the machine can automatically perform cutting according to the given program.

The gas cutting process mainly includes the pressure of the cutting oxygen, cutting speed, efficiency of the preheating flame, the tilt angle of the cutting nozzle and workpiece, and the distance between the cutting nozzle and the workpiece.

1) Pressure of the cutting oxygen:

It is influenced by the thickness of the workpiece, the type of cutting nozzle, and the purity of the oxygen.

When cutting thin materials, a smaller cutting nozzle size and lower oxygen pressure should be selected.

The purity of the oxygen has a significant impact on cutting speed, gas consumption, and cut quality.

2) Cutting speed:

It depends on the thickness of the workpiece and the shape of the cutting nozzle. As the thickness increases, the cutting speed decreases.

The cutting speed should not be too fast or too slow, as it can result in excessive drag and incomplete cuts.

The correctness of the cutting speed is mainly judged based on the amount of drag in the cut.

3) Efficiency of the preheating flame:

A neutral flame or a slightly oxidizing flame is used for preheating in gas cutting, and a carburizing flame should not be used.

The efficiency of the preheating flame is expressed in terms of the consumption rate of the combustible gas per hour.

The efficiency of the preheating flame is related to the thickness of the workpiece.

4) Tilt angle of the cutting nozzle and workpiece:

The tilt angle of the cutting nozzle and workpiece is determined primarily by the thickness of the workpiece.

The tilt angle of the cutting nozzle and workpiece directly affects the cutting speed and drag.

A backward tilt can reduce drag and increase cutting speed.

5) Distance between the cutting nozzle and the workpiece surface:

The distance between the cutting nozzle and the workpiece surface should be determined based on the length of the preheating flame and the thickness of the workpiece, generally around 3 to 5mm.

When δ<20mm, the flame can be longer, and the distance can be increased accordingly.

When δ>=20mm, the flame should be shorter, and the distance can be reduced.

6) Quality requirements of gas cutting cuts:

The surface of the gas cutting cut should be smooth and clean, with consistent coarse and fine lines. The iron oxide slag produced during gas cutting is easy to detach. The gap of the gas cutting cut should be narrow and consistent, and there should be no melting of the steel plate edges.

Evaluation criteria and grading of cut quality:

a) Surface roughness: Surface roughness refers to the distance between the peaks and valleys on the cutting surface (average of five arbitrary points), indicated by G.

b) Flatness: Flatness refers to the level of unevenness along the cutting direction perpendicular to the cutting surface. It is calculated as a percentage of the thickness δ of the cut steel plate, indicated by B.

c) Degree of upper edge melting: This refers to the extent of melting or collapse during the gas cutting process, manifested by the presence of collapsed corners and the formation of intermittent or continuous droplets or melted strips, indicated by S.

d) Slag hanging: Slag hanging refers to the iron oxide adhering to the lower edge of the cut surface. It is classified into different grades based on the amount of adhesion and the difficulty of removal, indicated by Z.

e) Maximum defect spacing: Maximum defect spacing refers to the appearance of grooves on the cut surface along the cutting line direction due to vibrations or interruptions, causing a sudden decrease in surface roughness. The depth of the groove is between 0.32mm to 1.2mm, and the width of the groove does not exceed 5mm. Such grooves are considered defects. The maximum defect spacing is indicated by Q.

f) Straightness: Straightness refers to the gap between the straight line connecting the starting and ending points along the cutting direction and the crown-like cloud cutting surface. It is indicated by P.

g) Perpendicularity: Perpendicularity refers to the maximum deviation between the actual cut surface and the perpendicular line to the surface of the metal being cut.

7) Causes and prevention methods of common defects:

(1) Excessive width and rough surface of the cut:

This is caused by excessive cutting oxygen pressure. When the cutting oxygen pressure is too low, the slag cannot be blown away, causing the slag to stick together and difficult to remove.

Prevention: Adjust the cutting oxygen pressure to an appropriate level for the desired cut width and surface roughness.

(2) Uneven surface or melting of edges:

This is caused by excessive preheating flame intensity or slow cutting speed. Insufficient preheating flame intensity can lead to interruptions in the cutting process and an uneven surface.

Prevention: Ensure an appropriate preheating flame intensity to achieve a regular and even cut.

(3) Excessive drag after cutting:

This occurs when the cutting speed is too fast, resulting in excessive drag and incomplete cuts. In severe cases, the slag may fly upwards and cause reheat.

Prevention: Adjust the cutting speed to an appropriate level to achieve proper cutting without excessive drag.

8) Ways to improve the surface quality of the cut:

(1) Proper cutting oxygen pressure:

Excessive cutting oxygen pressure can result in a wider cut and a rough surface, while wasting oxygen. Insufficient cutting oxygen pressure can cause the slag to stick together and be difficult to remove.

Solution: Adjust the cutting oxygen pressure to an appropriate level for the desired cut quality.

(2) Proper preheating flame intensity:

Excessive preheating flame intensity can lead to melting of the edges on the cut surface, while insufficient intensity can cause interruptions in the cutting process and an uneven surface.

Solution: Ensure an appropriate preheating flame intensity for a smooth and even cut.

(3) Proper cutting speed:

When the cutting speed is too fast, it can result in excessive drag, incomplete cuts, and the slag flying upwards, leading to reheat. When the cutting speed is too slow, the edges of the steel plate may melt, waste gas, and thinner plates may experience excessive deformation and adhesion, making post-cut cleaning difficult.

Solution: Adjust the cutting speed to an appropriate level for the desired cut quality.

1. Gas cutting is faster than other mechanical cutting methods, making it more efficient.

2. It is more cost-effective to use oxygen-acetylene cutting for cutting sections with difficult shapes and thicknesses that are challenging for mechanical cutting methods.

3. The investment in gas cutting equipment is lower compared to mechanical cutting, and the equipment is lightweight and portable, making it suitable for field operations.

4. When cutting small arcs, the cutting direction can be quickly changed. When cutting large workpieces, there is no need to move the workpiece itself; only the oxygen-acetylene flame needs to be moved for quick cutting.

5. Gas cutting can be done manually or mechanically.

6. The equipment is portable and can be used on-site.

7. Large metal sheets can be quickly cut on-site by moving the cutting torch instead of moving the metal block.

1. The dimensional tolerance is significantly lower than that of mechanical cutting tools.

2. Although gas cutting can also cut metals prone to oxidation, such as titanium, this process is mainly limited to cutting steel and cast iron in industrial applications.

3. The preheating flame and the emitted red-hot slag pose a risk of fire and burns to operators.

4. Proper smoke control and ventilation facilities are required for fuel combustion and metal oxidation.

5. Cutting high-alloy steels and cast irons may require process improvements.

6. Cutting high-hardness steels may require preheating before cutting and continued heating after cutting to control the metallurgical structure and mechanical properties near the cut edge.

7. Gas cutting is not recommended for long-distance cutting over a large area.

1. Widely used for steel plate cutting and preparing weld bevels.

2. Suitable for cutting the gating systems of castings, with cutting thicknesses of up to 300mm or more.

3. Mainly used for cutting various types of carbon steel and low-alloy steel.

4. When cutting high-carbon steel and low-alloy steel with a tendency for quenching, to avoid hardening or cracking at the cut edge, it is necessary to increase the preheating flame intensity and slow down the cutting speed, or even preheat the steel material before cutting.