Ever wondered what those numbers and letters on welding rods mean? This article demystifies the coding system for carbon and stainless steel welding rods, helping you understand their tensile strength, welding positions, and coating types. Get ready to enhance your welding knowledge and make informed choices for your projects!

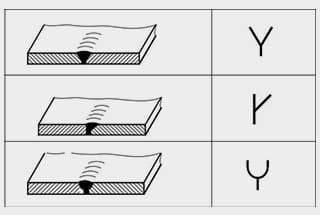

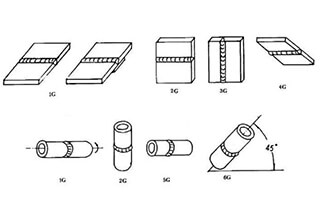

The E in carbon steel welding rod indicates the rod, the first two digits represent the minimum tensile strength of the deposited metal, the third digit represents the welding position, and the combination of the third and fourth digits represents the type of welding current and the type of coating.

For stainless steel welding rods, E stands for the rod, the numbers following “E” represent the classification code of the chemical composition of the deposited metal, and the two digits following “-” represent the type of coating, welding position, and type of welding current.

For more specifics, you can refer to GB5117 and GB983.

| No. | Grade | Model | ||||

| GB | AWS | JIS | DIN | |||

| E43 Series – Tensile Strength of Deposited Metal≥420Mpa(43kgf/mm2) | ||||||

| 1 | CHE40 | J421 | E4313 | E6013 | D4313 | E4332 R3 |

| 2 | CHE420T | J420G | E4300 | |||

| 3 | CHE421 | J421 | E4313 | E6013 | D4313 | E4332 R3 |

| 4 | CHE421Fe16 | J421Fe16 | E4324 | E6024 | ||

| 5 | CHE421Fe18 | J421Fe18 | E4324 | E6024 | ||

| 6 | CHE421D | J421X | E4313 | E6010 | D4313 | E4333R (C) 3 |

| 7 | CHE42 | J422 | E4303 | E6019 | D4303 | |

| 8 | CHE422 | J422 | E4303 | D4303 | ||

| 9 | CHE423 | J423 | E4301 | D4301 | ||

| 10 | CHE424 | J424 | E4320 | E6020 | D4320 | E4354AR11160 |

| 11 | CHE424Fe16 | J424Fe16 | E4327 | E6027 | D4327 | E4354AR11160 |

| 12 | CHE425 | J425 | E4311 | E6011 | D4311 | |

| 13 | CHE425G | J425G | E4310 | E6010 | ||

| 14 | CHE425GX | J425G | E4310 | E6010 | E4343C4 | |

| 15 | CHE426 | J426 | E4316 | E6016 | D4316 | E4343B10 |

| 16 | CHE47 | J427 | E4315 | |||

| 17 | CHE427 | J427 | E4315 | |||

| 18 | CHE427T | J427X | E4315 | |||

| E50 Series – Tensile Strength of Deposited Metal≥490Mpa(50kgf/mm2) | ||||||

| 1 | CHE501Fe | J501Fe | E5014 | E7014 | E4321AR11120 | |

| 2 | CHE501Fe16 | J501Fe16 | E5024 | E7024 | E5142RR11160 | |

| 3 | CHE502 | J502 | E5003 | D5003 | ||

| 4 | CHE503 | J503 | E5001 | |||

| 5 | CHE505 | J505 | E5011 | E7011-A1 | ||

| 6 | CHE505G | E5010 | E7010-A1 | |||

| 7 | CHE505GX | E5010 | E7010-A1 | |||

| 8 | CHE56 | J506 | E5016 | E7016 | D5016 | E5154B (R) 10 |

| 9 | CHE506 | J506 | E5016 | E7016 | D5016 | E51431310 |

| 10 | CHE50 | J507 | E5015 | E7015 | ||

| 11 | CHE507 | J507 | E5015 | E7015 | E51551310 | |

| 12 | CHE507T | J507X | E5015 | E7015 | E51551310 | |

| 13 | CHE507Fe16 | J507Fe16 | E5028 | E7028 | D5026 | E5155B (R) /2160 |

| 14 | CHE58-1 | E5018-1 | E7018-1 | D5016 | E5154B (R) 10 | |

| 15 | CHE508-1 | E5018-1 | E7018-1 | E5154B10 | ||

| 16 | CHE508 | E5018 | E7018 | D5016 | E5153B10 | |

| 17 | CHE508T | E5048 | E7048 | |||

Please refer to: GB/T 5117-1995 “Carbon Steel Electrodes for Shielded Metal Arc Welding.

Comparison of Old and New Designations for Commonly Used Carbon Steel Welding Rods and Their Applicable Scope:

| National Standards GB980-77 | National Standards GB5117-95 | Using Power Supply | Drying Temperature and Time (℃×h) | Suitable for welding steel materials. |

| J421 | E4320 | Direct Connection of Alternating or Direct Current | 150—200×1 | Flat welding and angle welding of A3, Q235A, Q235F, 10, 20 steel |

| J422 | E4303 | Direct Connection of Alternating or Direct Current | 150—200×1 | A3, Q235A, Q235F, 10, 20 |

| J423 | E4301 | Direct Connection of Alternating or Direct Current | 150—200×1 | A3, Q235A, Q235F, 10, 20 |

| J427 | E4315 | Reverse Connection of Direct Current | 350—400×2 | Q235B, C, D, 20R, 20g |

| J502 | E5003 | Direct Connection of Alternating or Direct Current | 150—200×1 | Q295, Q345, 16Mn, etc. |

| J506 | E5016 | Reverse Connection of Direct Current or Alternating Current | 350—400×2 | Q295, Q345, 16Mn, 16MnR, etc. |

| J507 | E5015 | Reverse Connection of Direct Current | 350—400×2 | Q295, Q345, 16Mn, 16MnR, etc. |

Low Alloy Steel Welding Rod:

| No | Grade | GB | AWS | JIS | DIN | |

| 1 | CHE502WCu | J502Wcu | TBE5003-G | |||

| 2 | CHE505Mo | E5010-A1 | E7010-A1 | |||

| 3 | CHE506NiLH | E5016-G | E7016-G | |||

| 4 | CHE506WCu | J506Wcu | TBE5016-G | |||

| 5 | CHE507NiLH | E5015-G | E7015-G | |||

| 6 | CHE507RH | E5015-G | ||||

| 7 | CHE507CuP | J507CuP | E5015-G | E7015-G | ||

| 8 | CHE507MnMo | E5015-G | E7015-G | |||

| 9 | CHE507CrNi | J507CrNi | E5015-G | E7015-G | ||

| 10 | CHE507GX | |||||

| 11 | CHE508Ni | E5018-G | E7018-G | |||

| 12 | CHE555GX | E5510-G | E8010-P1 | |||

| 13 | CHE557 | J557 | E5515-G | E8015-G | D5316 | EY5066NiMoBH5 |

| 14 | CHE557MoV | J557MoV | E5515-G | E8015-G | D5316 | EY5066NiMoBH5 |

| 15 | CHE557GX | |||||

| 16 | CHE558GX | |||||

| 17 | CHE62CFLH | E6015-G | E9015-G | D5816 | E55548XXH5 | |

| 18 | CHE606 | J606 | E6016-D1 | E9016-G | D5816 | E55548XXH5 |

| 19 | CHE607 | J607 | E6015-D1 | E9015-G | D5816 | DY5554BXXH5 |

| 20 | CHE607Ni | J607Ni | E6015-G | E9015-G | D5816 | EY5554BXXH5 |

| 21 | CHE607GX | |||||

| 22 | CHE707 | J707 | E7015-D2 | E10015-G | D7016 | EY624BXXH5 |

| 23 | CHE707MnMo | E7015-G | E10015-G | D7016 | EY624BXXH5 | |

| 24 | CHE707Ni | J707Ni | E7515-G | E10015-G | D7016 | EY624BXXH5 |

| 25 | CHE757 | J757 | E7517-G | E11015-G | D7016 | EY6924BXXH15 |

| 26 | CHE758 | E7518-G | E11018-G | |||

| 27 | CHE80C | E8015-G | E12015-G | |||

| 28 | CHE857 | J857 | E8515-G | E12015-G | EY7953BXXH15 | |

| 29 | CHE857Cr | J857Cr | E8515-G | E12015-G | EY7953BXXH15 | |

| 30 | CHE857CrNi | J857CrNi | E8515-G | E12015-G | EY7953BXXH15 | |

| 31 | CHE858 | E8518-G | E12018-G | |||

| 32 | CHH107 | R107 | E5015-A1 | E7015-A1 | DT1216 | EMoB10+ |

| 33 | CHH108 | E5018-A1 | E7018-A1 | |||

| 34 | CHH202 | R202 | E5503-B1 | |||

| 35 | CHH207 | R207 | E5518-B1 | E8015-B1 | ||

| 36 | CHH307 | R307 | E5515-B2 | E8015-B2 | DT2315 | ECrMolB10+ |

| 37 | CHH308 | E5515-B2 | E8018-B2 | |||

| 38 | CHH317 | R317 | E5515-B2-V | E8016-B2 | DT2315 | |

| 39 | CHH327 | R327 | E5515-B2-VW | |||

| 40 | CHH337 | R337 | E5515-B2-VNb | |||

| 41 | CHH347 | R347 | E5515-B3-VWB | |||

| 42 | CHH347A | |||||

| 43 | CHH407 | R407 | E6015-B3 | E9015-B3 | DT2415 | EcCrMo2B10+ |

| 44 | CHH417 | R417 | E5515-B3-VNb | |||

| 45 | HL107 | W107 | E5015-C2L | E7015-C2L | ||

| 46 | HL707 | W707 | E5515-Cl | E8015-C1 | ||

| 47 | HL907 | E7015-G | ||||

Comparison of old and new model numbers of alloy steel welding rods, and their application scope:

| National Standards GB982-77 | National Standards GB5118-95 | Drying | Suitable for welding steel materials. |

| R102 | E5003-A1 | 150~200℃×1 h | Preheat 15Mo to 90-110°C, then temper at 605-635°C. |

| R107 | 350℃×1 h | ||

| R202 | E5503-B1 | 150~200℃×1 h | Preheat 12CrMo to 150-200°C, then temper at 605-635°C. |

| R207 | 350℃×1 h | ||

| R302 | E5503-B2 | 150~200℃×1 h | Preheat 15CrMo at 160-200℃, temper at 675-705℃. |

| R307 | E5515-B2 | 350℃×1 h | |

| R312 | E5503-B2-V | 200℃×1 h | Preheat 12CrMoV at 250-300℃, temper at 715-745℃. |

| R317 | E5515-B2-V | 350℃×1 h | |

| R327 | E5515-B2-VW | Preheat 15CrMoV to 250-300℃, then temper at 715-745℃. | |

| R337 | E5515-B2-VNb | ||

| R402 | E6003-B3 | 200℃×1 h | Preheat 12Cr2Mo at 160-200℃, temper at 675-705℃. |

| R407 | E6015-B3 | 350℃×1 h | |

| R417 | E5515-B3-VNb | Preheat 12Cr3Mo3SiTiB at 200-300℃, then temper at 715-745℃. | |

| R507 | E15MoV-15 | Cr5Mo should be preheated at 300 to 400 degrees Celsius, followed by tempering treatment at 740 to 760 degrees Celsius. | |

| R707 | E9Mo-15 | Cr5Mo should be preheated at 300 to 400℃, and then tempered at 730 to 750℃. | |

| R802 | E11MoVNi-16 | 1Cr11MoV should be preheated at 300-400°C, then tempered at 730-750°C. | |

| R807 | E11MoVNi-15 | ||

| R817 | E11MoVNiW-15 | Cr11MoNiVW should be preheated at 350-450℃, and then undergo tempering treatment at 730-750℃. | |

| R827 | Cr11MoNiV; Preheat Cr11MoV at 350 to 450℃, then temper at 730 to 750℃. |

Description: E5003-A1 – Carbon Molybdenum Steel; E5503-B1, B2, B3 – Increased Chromium content, Chromium Molybdenum Steel; E5515-C2, C2, C3 – Increased Nickel content, Nickel Steel; E5518-NM – Nickel Molybdenum Steel; W6015-D1, D2, D3 – Increased Manganese content, Manganese Molybdenum Steel; E××10-G, E××03-G, etc.: Other low alloy steel welding rods.

| No | Grade | GB | AWS | JIS | DIN | |

| 1 | CHH507 | R507 | E5MoV-15 | E502-15 | DT2516 | EkbCrMo520+ |

| 2 | CHH707 | R707 | E9Mo-15 | E505-15 | EkbCrMo920+ | |

| 3 | CHH807 | R807 | E11MoVNi-15 | |||

| 4 | CHK202 | G202 | E410-16 | E410-16 | D410 | E13B20+ |

| 5 | CHK207 | G207 | E410-15 | E410-15 | E13B20+ | |

| 6 | CHK232 | E410NiMo-16 | E410NiMo-16 | |||

| 7 | CHK307 | G307 | E430-15 | E430-15 | D430 | E17B20+ |

| 8 | CHS002 | A002 | E308L-16 | E308L-16 | D308L | E199ncR23 |

| 9 | CHS002A | E308L-15 | E308L-15 | |||

| 10 | CHS012Si | A012Si | ||||

| 11 | CHS022 | A022 | E316L-16 | E316L-16 | D316L | E19123ncR26 |

| 12 | CHS022N | E316L-16 | E316L-16 | D316L | E19123ncR26 | |

| 13 | CHS022Si | A022Si | ||||

| 14 | CHS032 | A032 | E317MoCuL-16 | E317L-16 | ||

| 15 | CHS042 | A042 | E309MoL-16 | E309MoL-16 | ||

| 16 | CHS052 | A052 | ||||

| 17 | CHS052Cu | |||||

| 18 | CHS062 | A062 | E309L-16 | E309L-16 | ||

| 19 | CHS062A | E309L-15 | E309L-15 | |||

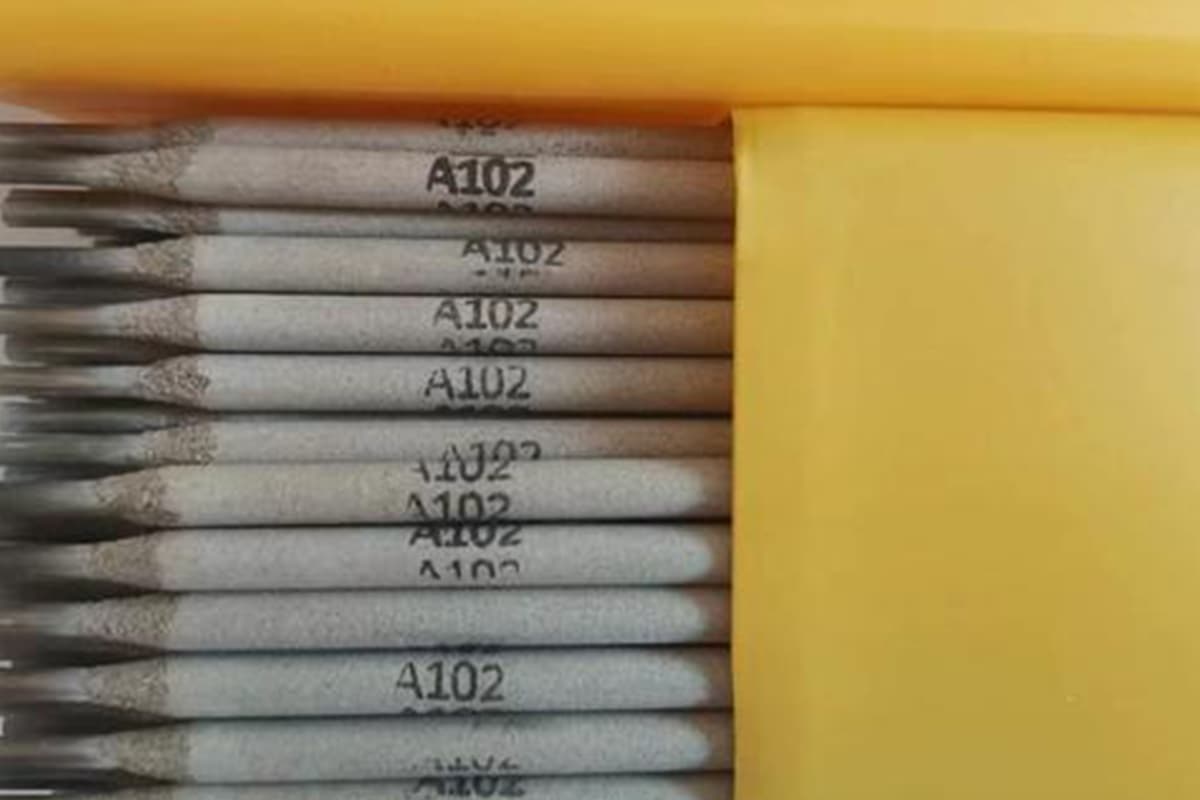

| 20 | CHS102 | A102 | E308-16 | E308-16 | D308-16 | E199R26 |

| 21 | CHS107 | A107 | E308-15 | E308-15 | E199B26 | |

| 22 | CHS122 | A122 | ||||

| 23 | CHS132 | A132 | E347-16 | E347-16 | D347-16 | E199NbR26 |

| 24 | CHS137 | A137 | E347-15 | E347-15 | D347-15 | E199NbB26 |

| 25 | CHS157Mn | |||||

| 26 | CHS202 | A202 | E316-16 | E316-16 | D316 | E19123R26 |

| 27 | CHS207 | A207 | E316-15 | E316-15 | E19123B20+ | |

| 28 | CHS212 | A212 | E318-16 | E318-16 | E19123NbR26 | |

| 29 | CHS222 | A222 | E317MoCu-16 | E316Cu-16 | ||

| 30 | CHS232 | A232 | E318V-16 | |||

| 31 | CHS237 | A237 | E318V-15 | |||

| 32 | CHS302 | A302 | E309-16 | E309-16 | D309-16 | E2312R26 |

| 33 | CHS307 | A307 | E309-15 | E309-15 | D309-15 | E2212B20+ |

| 34 | CHS312 | A312 | E309Mo-16 | E309Mo-16 | D309Mo-16 | E2312R26 |

| 35 | CHS402 | A402 | E310-16 | E310-16 | D310-16 | E2520R26 |

| 36 | CHS407 | A407 | E310-15 | E310-15 | D310-15 | E2520B26 |

| 37 | CHS412 | A412 | E310Mo-16 | E310Mo-16 | D310Mo-16 | |

| 38 | CHS437 | E310H-15 | B.S:25.20H | |||

| 39 | CHS502 | A502 | E16-25MoN-16 | E16-8-2-16 | D16-8-2 | |

| 40 | CHS507 | A507 | E16-25MoN-15 | E16-8-2-15 | D16-8-2 | |

| 41 | CHS29.9 | E312-16 | E312-16 | D312 | ||

| 42 | CHS29.9Co | |||||

| 43 | CHS2209 | E2209-16 | E2209-16 | |||

Comparison of old and new models of stainless steel welding rods and their application range:

| National Standards GB983-77 | National Standards GB983-85 | National Standards GB983-95 | Drying | Suitable for welding steel materials |

| A002 | E00-19-10-16 | E308L-16 | 150℃×1 h | 0Cr19Ni10; 0Cr19Ni11Ti; |

| A022 | E00-18-12Mo-16 | E316L-16 | 00Cr17Ni14 Mo2 | |

| A032 | E00-19-13Mo2-Cu2-16 | E317 Mo-CuL-16 | 0Cr18Ni12Mo2Cu2 | |

| A042 | E00-23-13Mo2-16 | E309 Mo L-16 | 00Cr23Ni13Mo2 | |

| A062 | E00-23-13-16 | E309 L-16 | 00Cr23Ni13 | |

| A101 | E0-19-10-16 | E308-16 | 1Cr19Ni9; Cr19Ni10; 0Cr19Ni11 | |

| A102 | E0-19-10-16 | E308-16 | 0Cr19Ni9; 0Cr19Ni11Ti | |

| A107 | E0-19-10-15 | E308-15 | 250℃×1 h | 0Cr19Ni9 |

| A132 | E0-19-10Nb-16 | E347-16 | 150℃×1 h | Cr19Ni11Ti |

| A137 | E0-19-10Nb-15 | E347-15 | 250℃×1 h | 0Cr19Ni11Ti |

| A201 | E0-18-12Mo2-16 | E316-16 | 250℃×1 h(Prohibit repeated baking.) | 0Cr18Ni12Mo2 |

| A202 | E0-18-12Mo2-16 | E316-16 | 150℃×1 h | 0Cr18Ni12Mo2 |

| A207 | E0-18-12Mo2-15 | E316-15 | 250℃×1 h | 0Cr18Ni12Mo2; Cr13; Cr17 |

| A242 | E0-19-13Mo3-16 | E317-16 | 150℃×1 h | Cr19Ni13Mo3 |

| A302 | E1-23-13-16 | E309-16 | Cr23Ni13 | |

| A307 | E1-23-13-15 | E309-15 | 250℃×1 h | Cr23Ni13 |

| A312 | E1-23-13Mo2-16 | E309 Mo -16 | 150℃×1 h | Cr23Ni13Mo2 |

| A402 | E2-26-21-16 | E310 -16 | Cr25Ni20 | |

| A407 | E2-26-21-15 | E310 -15 | 250℃×1 h | Cr25Ni20 |

| A412 | E1-21-21Mo2-16 | E310Mo -16 | 150℃×1 h | Cr26Ni21Mo2 |

| A422 | Cr25Ni20Si2 |

Description: 15, 25 – Alkaline, direct current reversed polarity; 16, 17, 26 – Titanium calcium type, alternating current or direct current reversed polarity.

| No | Grade | GB | AWS | JIS | |

| 1 | CHC100 | Z100 | |||

| 2 | CHC | Z | |||

| 3 | CHC208 | Z208 | EZC | ||

| 4 | CHC308 | Z308 | EZNi-1 | ENi-CI | DECNi |

| 5 | CHC408 | Z408 | EZNiFe-1 | ENiFe-CI | DFCNiFe |

| 6 | CHC508 | Z508 | EZNiCu-1 | ENiCu-B | DFCNiCu |

Comparison of old and new model numbers for low temperature steel welding rods and their application range

| National Standards GB982-77 | National Standards GB5118-95 | Drying | Suitable for welding steel materials. |

| W707 | 350℃×1 h | 09Mo2V; 09MnTiCuXi | |

| W707Ni | E5515-C1 | 09Mo2V; 16MnVAl; 3.5Ni Steel, etc. | |

| W907Ni | E5515-C2 | 3.5Ni steel should be preheated to 150℃, then tempered at a temperature range of 600-650℃. | |

| W107Ni | 06AlNbCuN;16MnNb; 3.5Ni steel |

| No | Grade | Welding Forms | GB | AWS | DIN | JIS |

| 1 | CHW-40CNH | Gas Shielded Welding | TB/T H08MnSiCuCrNi Ⅱ | |||

| 2 | CHW-50C | Gas Shielded Welding | ER49-1 | |||

| 3 | CHW-50C3 | Gas Shielded Welding | ER50-3 | ER70S-3 | YGW16 | |

| 4 | CHW-50C6 | Gas Shielded Welding | ER50-6 | ER70S-6 | SG2 | YGW12 |

| 5 | CHW-50C8 | Gas Shielded Welding | ER70S-G | |||

| 6 | CHW-60C | Gas Shielded Welding | ER80S-G | |||

| 7 | CHW-62B3 | Gas Shielded Welding | ER62-B3 | ER80S-B3 | ||

| 8 | CHW-S1 | Submerged Arc Welding | H08A (E) | EL12 | S1 | |

| 9 | CHW-S2 | Submerged Arc Welding | H08MnA | EM12 | S2 | |

| 10 | CHW-S3 | Submerged Arc Welding | H10Mn2 | EH14 | S4 | W41 |

| 11 | CHW-S4 | Submerged Arc Welding | H10MnSi | EM13K | ||

| 12 | CHW-S5 | Submerged Arc Welding | H08Mn2SiA | |||

| 13 | CHW-S6 | Submerged Arc Welding | ER50-6 | |||

| 14 | CHW-S7 | Submerged Arc Welding | H008Mn2MoA | |||

| 15 | CHW-S8 | Submerged Arc Welding | H13Cr2.25MolA | EB3 | ||

| 16 | CHW-S9 | Submerged Arc Welding | HO8MnMoA | EA2 | ||

| 17 | CHW-SG | Submerged Arc Welding | ||||

| 18 | CHW-SQ1 | Submerged Arc Welding | ||||

| 19 | CHW-SQ2 | Submerged Arc Welding | ||||

| 20 | CHW-G1 | Gas Welding | H08A | EL12 | 8557-S1 |

Welding Fluxes for Carbon Steel and Low Alloy Steel:

| No | Grade | GB | AWS | |

| 1 | CHF101 | SJ101 | F5A2-H10Mn2 | E7A0-EH14 |

| 2 | CHF101GX | |||

| 3 | CHF102 | F5A4-H10Mn2 | E7A4-EH14 | |

| 4 | CHF103 | SJ103 | F4A4-H108MnA | E6A4-EM12 |

| 5 | CHF105 | SJ105 | F5P5-H10Mn2 | E7P6-EH14 |

| 6 | CHF105GX | |||

| 7 | CHF105HR | F5131-H10Mn2 | E7P2-EH14 | |

| 8 | CHF106Fe | F5A2-H10Mn2 | E7A0-EH14 | |

| 9 | CHF113 | F7141-H08Mn2MoA | F62P4-EA4-A4 | |

| 10 | CHF115 | F8121-H08Mn2MoA | F69P2-EA4-A4 | |

| 11 | CHF201 | SJ201 | F5A4-H10Mn2 | E6A0-EM12 |

| 12 | CHF250 | HJ250 | ||

| 13 | CHF301 | SJ301 | F4A2-H08A | E6A0-EL12 |

| 14 | CHF302 | SJ302 | F5A2-H08A | E7A0-EL12 |

| 15 | CHF303 | SJ303 | F5A2-H10MnSi | F7A0-EM13K |

| 16 | CHF330 | HJ330 | F4A0-H10Mn2 | F6AZ-EH14 |

| 17 | CHF350 | HJ350 | F4A2-H10Mn2 | F6A0-EH14 |

| 18 | CHF360 | HJ360 | ||

| 19 | CHF431 | HJ431 | F4A2-H08A | F6A0-EL12 |

| 20 | CHF501 | SJ501 | F4A0-H08A | F6AZ-EL12 |

| 21 | CHF523 | F4A0-H08A | F6AZ-EL12 | |

| 22 | CHFGP60 | F4A0-H08A | F6AZ-EL12 | |

| 23 | CHF603 | |||

| 24 | CHF603HR |

Welding Fluxes for Stainless Steel, Non-ferrous Metals, and Repair Welding:

| No | Grade | GB | |

| 1 | CHF131 | HJ131 | |

| 2 | CHF150 | HJ150 | |

| 3 | CHF202 | SJ202 | |

| 4 | CHF203 | SJ203 | |

| 5 | CHF260 | HJ260 | F308-H0Cr21Ni10 |

| 6 | CHF304D | ||

| 7 | CHF521 | ||

| 8 | CHF522 | SJ522 | |

| 9 | CHF570 | SJ570 | |

| 10 | CHF601 | SJ601 | F308-H0Cr21Ni10 |