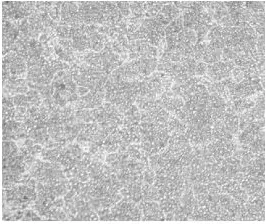

After martensite quenching and tempering, the structure of high-carbon chromium steel bearing parts should be cryptocrystalline or fine-crystalline with small acicular martensite. Additionally, it should have evenly distributed fine residual carbide and a small amount of residual austenite.

For micro-bearings, a small amount of acicular or massive troostite is permissible, as shown in Fig. 1.

The microstructure following quenching and tempering must comply with clause 3.2.2 of JB/T1255-2014, the technical specifications for heat treatment of high-carbon chromium bearing steel parts for rolling bearings.

This structure of high-carbon chromium bearing steel exhibits good hardness, strength, wear resistance, and fatigue resistance.

After tempering, the bearing steel can also acquire excellent comprehensive properties, such as elasticity, toughness, and dimensional stability.

During the heat treatment of high carbon chromium steel bearing parts, various defects can occur due to issues with bearing steel materials, the heat treatment process, processing equipment, and human factors. Such defects can include overheating of the metallographic microstructure (coarse needle martensite), underheating of the metallographic microstructure (troostite exceeding the standard), coarse grain carbides, serious network carbides, and other microstructure defects.

Some of these metallographic microstructure defects can directly cause product scrapping, such as the overheated metallographic microstructure (coarse needle martensite). However, other defects may not result in the product being scrapped, but they can still negatively impact the product’s service life.

For instance, under-heated metallographic microstructure (troostite exceeding the standard) can affect the bearing’s service life, leading to early ring breakage of the bearing and significantly impacting the quality of the bearing product.

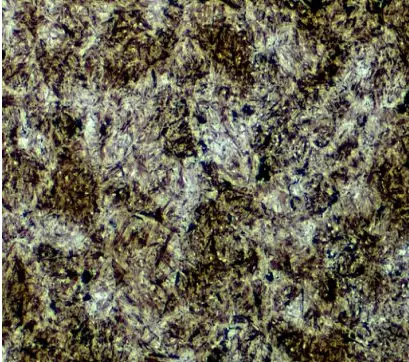

1. Quenching superheated metallographic microstructure (coarse needle martensite)

Figures 2 and 3 depict the metallographic microstructure resulting from quenching at a superheat temperature, exhibiting coarse acicular martensite with distinct structural characteristics. This type of structure is known to decrease the toughness and impact resistance of the bearing, leading to a shorter service life and even quenching cracks in cases of severe overheating.

(1) Cause

This issue is mainly caused by excessively high quenching heating temperature or extended holding time at the upper limit of quenching heating temperature, which results in excessive dissolution of secondary carbides. The austenite grain is also given an opportunity to grow, weakening the hindering effect on the growth of martensite and increasing the possibility of larger martensite growth.

When viewed under a 500x (or 1000x) metallographic microscope, the overheated metallographic microstructure is evident as coarse needle martensite.

Another possible cause is the presence of seriously banded carbides in the raw material or uneven size distribution of carbides in the annealed structure, resulting in fine flake pearlite in the annealed structure.

Even during normal quenching, coarse acicular martensite may form in areas with sparsely distributed carbides or fine particles, with few obstacles to martensite growth.

Surface decarburization results in little to no carbides, and therefore has a minimal effect on hindering martensite growth.

If cooling conditions are optimal, martensite still has a chance to grow and form coarse acicular martensite.

(2) Measures

It is important to choose an appropriate quenching temperature and heating time. These parameters should be selected in accordance with the material standards, and it is necessary to strictly control the formation of carbide bands.

To enhance the quality of annealing, it is crucial to monitor the furnace temperature closely during production. In case of any power or equipment failure, timely and effective measures should be taken to prevent any negative impact on the process.

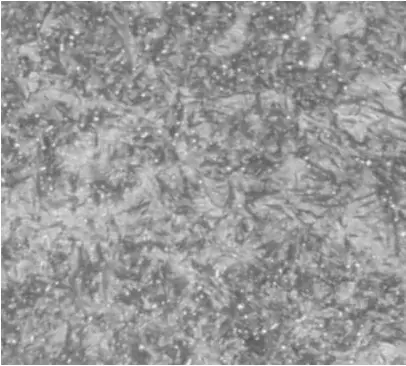

2. Metallographic microstructure of quenching under heating (troostite exceeds the standard)

Troostite is a structure that forms due to undercooling or poor cooling during the cooling process. It is the result of the pearlite transformation of austenite.

Troostite has an exceptionally fine pearlite structure. In bearing steel, troostite can be categorized based on its metallographic morphology into four types: massive troostite (see Fig. 4), acicular troostite (see Fig. 5), a combination of acicular and massive structures (see Fig. 6), and banded troostite (see Fig. 7).

The troostite structure can be found in quenched bearing steel, and it can lead to a decrease in both the hardness and strength of the steel. This structure is also unfavorable for wear and fatigue resistance, and it greatly reduces the rust resistance of bearing steel.

Although the hardness of the part is within the qualified range, the presence of a small amount of acicular and massive troostite does meet the metallographic microstructure requirements specified in JB/T1255-2014 technical conditions for heat treatment of high carbon chromium bearing steel parts for rolling bearings.

However, the presence of massive and reticular troostite exceeds the standard provisions, making it an unqualified structure. This may result in lower hardness of the part, and make it easier to identify soft spots after pickling.

(1) Cause

Massive troostite forms when there is inadequate heating (either the temperature is too low or the holding time is too short). This results in uneven austenitic alloying concentration and low hardenability in certain areas of the steel, leading to pearlite transformation during normal cooling.

Acicular troostite forms due to poor cooling, where the quenching medium is not able to cool the steel at a sufficient rate. Even with normal heating, certain areas of the steel may not reach the critical cooling rate necessary for proper hardening.

Zonal troostite forms when there are carbides present in the raw material of bearing steel that are distributed in a strip shape in areas with low carbon concentration.

(2) Measures

If troostite appears during production, its metallographic microstructure must be inspected, and the causes analyzed in order to take the appropriate measures.

If the troostite is in a massive form, the quenching heating temperature should be increased properly and the holding time extended.

If the troostite is in an acicular form, the cooling rate should be increased.

If the heating temperature, heat preservation, and cooling are within normal range but troostite still occurs, it is necessary to check for raw material problems, temperature control issues, equipment malfunctions, and other potential causes. It is important to identify the cause in a timely manner and take the necessary measures.

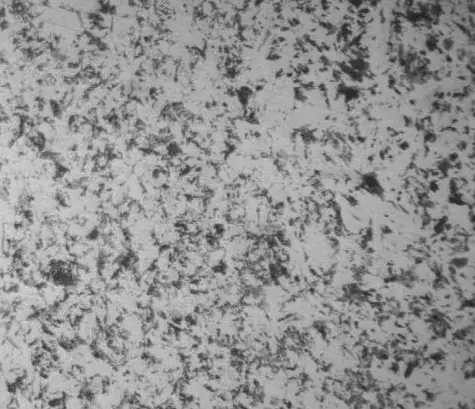

3. Severe network carbide

Figure 8 depicts the severe network carbide formation resulting from deep corrosion using a 4% nitric acid alcohol solution.

This structural defect does not arise during the quenching process but rather results from improper rolling, forging, or annealing. It can only be detected through inspection post-quenching.

(1) Cause

The presence of reticulated carbides in steel increases the inhomogeneity of its chemical composition. This can lead to significant structural stress during heat treatment and quenching, which in turn may cause deformation and cracking of parts.

Reticulated carbides weaken the relationship between the matrix grains, and reduce the mechanical properties of steel. In particular, they can greatly reduce the impact properties of steel. Furthermore, as the level of reticulated carbides increases, the impact properties of steel continue to decrease.

Network carbides also have a significant effect on the bending strength and tensile strength of steel. Additionally, the contact fatigue strength of steel decreases with an increase in the level of reticulated carbides. In fact, the contact fatigue strength of longitudinal specimens with coarse reticulated carbides decreases by approximately 30%.

Each grade increase of reticulated carbide reduces the service life of parts by approximately one-third. Severe reticulated carbides cannot be eliminated in subsequent spheroidizing annealing processes, and the structure of the carbides can only be eliminated or improved through a normalizing process.

In cases where the reticulated carbide is light, part of the network can be broken and spheroidized during spheroidizing annealing. However, if the carbide particles are larger, the carbide particles in the spheroidized annealed structure may not be uniform.

(2) Measures

Strict control should be implemented on the reticulated carbides present in the raw materials of bearing steel. The level of reticulated carbides should not exceed the limit specified in GB/T18254-2016 for high carbon chromium bearing steel.

During the forging process of bearing forgings, it is important to regulate the cooling rate to avoid the formation of reticulated carbides resulting from a slow cooling rate.

If necessary, air cooling may be utilized to hasten the cooling rate of forgings and prevent the occurrence of reticulated carbides.

4. Conclusion

An in-depth analysis of the causes of the primary defects in the microstructure of high-carbon chromium bearing steel parts after quenching has been conducted, and preventive and corrective measures have been proposed to improve the quenching quality of high-carbon chromium bearing steel parts.

Given the complexity of production practices, it is crucial to conduct a specific analysis of different situations to ensure the quenching quality of high-carbon chromium bearing steel parts and guarantee the reliable internal quality of bearing products.